Question: Assignment Note: When developing recommendations, please use the same assumptions as Jacobs's team. Those assumptions were 21 productive days per month and 6.5 productive work

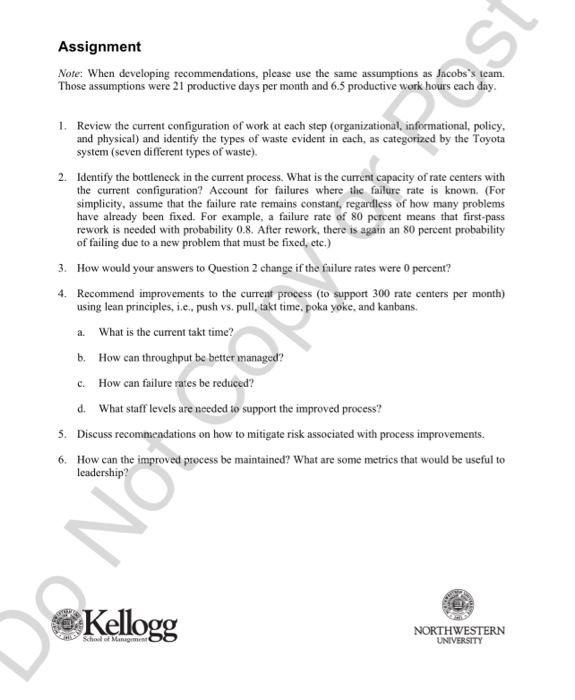

Note: When developing recommendations, please use the same assumptions as Jacobs's ieam. Those assumptions were 21 productive days per month and 6.5 productive work hours each day. 1. Review the current configuration of work at each step (organizational, informational, policy, and physical) and identify the types of waste evident in each, as categorized by the Toyota system (seven different types of waste). 2. Identify the bottleneck in the current process. What is the current capacity of rate centers with the current configuration? Account for failures where the failure rate is known. (For simplicity, assume that the failure rate remains constant, regardless of how many problems have already been fixed. For example, a failure rate of 80 percent means that first-pass rework is needed with probability 0.8 . After rework, there is again an 80 percent probability of failing due to a new problem that must be fixed, etc.) 3. How would your answers to Question 2 change if the failure rates were 0 percent? 4. Recommend improvements to the current process (to support 300 rate centers per month) using lean principles, i.c., push vs, pull, takt time, poka yoke, and kanbans. a. What is the current takt time? b. How can throughput be better managed? c. How can failure rates be reduced? d. What staff levels are needed to support the improved process? 5. Discuss recommendations on how to mitigate risk associated with process improvements. 6. How can the improved process be maintained? What are some metrics that would be useful to leadership

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts