Question: At this point, Besta Bikes has not utilized a second shift, even though they can use a maximum of 100 workers on any given shift.

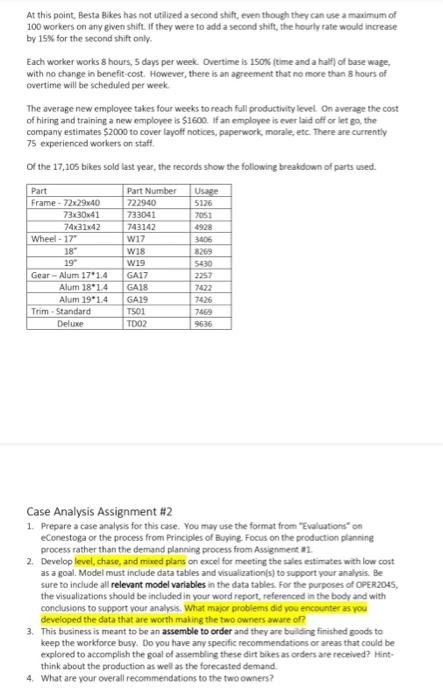

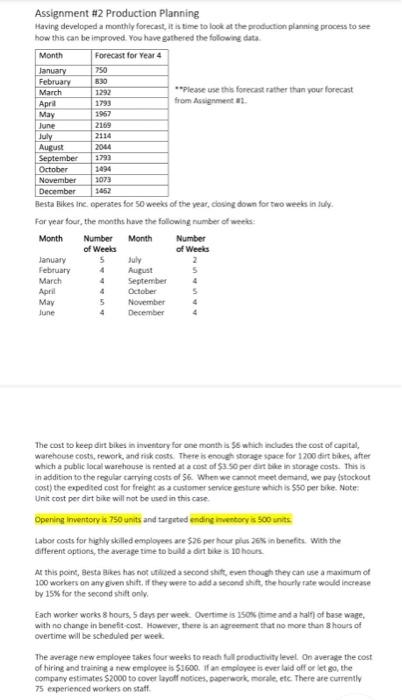

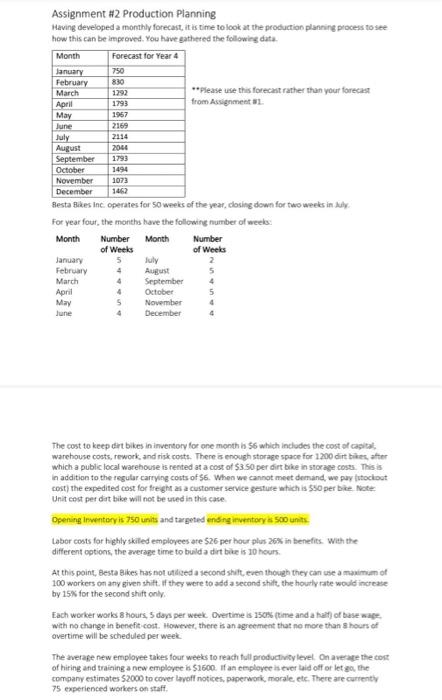

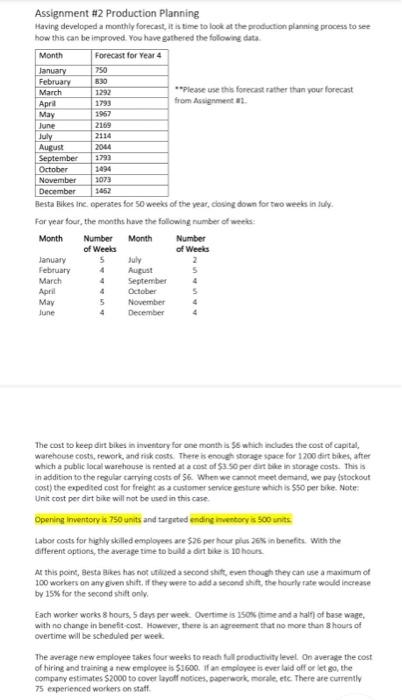

At this point, Besta Bikes has not utilized a second shift, even though they can use a maximum of 100 workers on any given shift. If they were to add a second shift, the hourly rate would increase by 15% for the second shift only Each worker works 8 hours, 5 days per week Overtime is 150% time and a half of base wage. with no change in benefit-cost. However, there is an agreement that no more than Bhours of overtime will be scheduled per week The average new employee takes four weeks to reach full productivity level. On average the cost of hiring and training a new employee is $1600. If an employee is everlaid off or let go, the company estimates $2000 to cover layoff notices, paperwork morale, etc. There are currently 75 experienced workers on staff of the 17,105 bikes sold last year, the records show the following breakdown of parts used. Usage Part Frame - 72x29x40 73x30x41 74x31x42 Wheel - 17" 189 19 Gear - Alum 17'1.4 Alum 18*1.4 Alum 1914 Trim - Standard Deluxe Part Number 722940 733041 743142 w17 W18 W19 GA17 GA18 GA19 TS01 TDO2 5126 7051 4928 3406 8269 5430 2257 7422 7426 7669 9636 Case Analysis Assignment #2 1. Prepare a case analysis for this case. You may use the format from "Evaluations on eConestoga or the process from Principles of Buyine. Focus on the production planning process rather than the demand planning process from Assignment #1 2. Develop level chase, and mored plans on excel for meeting the sales estimates with low cost as a goal. Model must include data tables and visualization(s) to support your analysis. Be sure to include all relevant model variables in the data tables for the purposes of OPER2045, the visualizations should be included in your word report, referenced in the body and with conclusions to support your analysis. What major problems did you encounter as you developed the data that are worth making the two owners aware of 3. This business is meant to be an assemble to order and they are building finished goods to keep the workforce busy. Do you have any specific recommendations or areas that could be explored to accomplish the goal of assembling these dirt bikes as orders are received? Hint think about the production as well as the forecasted demand 4. What are your overall recommendations to the two owners? 750 830 Assignment #2 Production Planning Having developed a monthly forecast, it is time to look at the production planning process to see how this can be improved. You have gathered the following data Month Forecast for Year 4 January February March 1292 **Please use this forecast rather than your forecast April from Assignment May June July August September October November December nesta likes the operates for 50 weeks of the year, ciesing down for two weeks in July For year four, the months have the following number of words Month Number Month Number of Weeks of Weeks January 5 July 2 February 4 August 5 March 4 September 4 April 4 October s May 5 November June 4 December 1793 1962 2169 2114 2014 1792 1494 1073 1452 The cost to keep dirt bikes in inventory for one month $6 which includes the cost of capital, warehouse costs, rework, and risk costs. There is noen storage space for 1200 dirt bikes, after which a public local warehouse's rented at a cost of $350 per dirt bike in storage costs. This is in addition to the regular carrying costs of 56. When we cannot meet demand, we pay stockout cost) the expedited cost for freight as a customer senice gesture which is 550 per bike. Note: Unit cost per dirt bike will not be used in this case. Opening Inventory is 750 units and targeted ending inventory is 500 units Labor costs for highly skilled employees we $26 per hour plus 26% in benefits. With the different options, the average time to build a dirt bikes 10 hours At this point, Besta Bikes has noted a second she even though they can use a maximum of 100 workers on any given shift, if they were to add a second thift, the hourly rate would increase by 15% for the second shift only Each worker works 8 hours, 5 days per week Overtime's 150time and a half of base wage. with no change in benefitcost. However, there is an agreement that no more than 8 hours of overtime will be scheduled per week The average new employee takes four weeks to reach productivity level On average the cost of hiring and training a new employee is $3600 fan employee is ever taid off or let go, the company estimates S2000 to cover layoff notices, work morale, etc. There are currently 75 experienced workers on staff Assignment #2 Production Planning Having developed a monthly forecast, it is time to look at the production planning process to see how this can be improved. You have gathered the following data. Month Forecast for Year 4 January February March **Please use this forecast rather than your forecast April from Assignment May June July August September October November December Besta Bikes Inc. operates for so weeks of the year, closing down for two weeks in My. For year fout, the months have the following number of weekes Month Number Month Number of Weeks of Weeks January 5 July 2 February 4 August 5 March 4 September 4 April 4 October 5 May 5 November June 4 December 4 750 830 1292 1793 1967 2169 2114 2044 1793 1494 1073 1462 The cost to keep it bikes in inventory for one month 656 which includes the cost of capital warehouse costs, rework and risk costs. There is enough storage space for 1200 dirt bikes after which a public local warehouse is rented at a cost of $3.50 per dirt bike in storage costs. This is In addition to the regular carrying costs of 56. When we cannot meet demand, we pay stockout cost the expedited cost for freght as a customer service gesture which is $50 per bie Note: Unit cost per dirt bike will not be used in this case, Opening inventory is 750 units and targeted ending inventory issunits. Labor costs for highly skilled employees are $26 per hour plus 26% in benefits. With the different options, the average time to build a dirt bike is 20 hours. At this point, Besta Bikes has noticed a second shit even though they can use a maximum of 100 workers on any given shift. If they were to add a second shift the hourly rate would increase by 15% for the second shift only Each worker works 8hours, 5 days per week. Overtime is 50% (time and a half of base wape with no change in benefit cost. However, there is an agreement that no more than 8 hours of overtime will be scheduled per week The average new employee takes four weeks to reach tail productivity level On average the cost of hiring and training a new employees $1600 of an employee is ever taid off or let go, the company estimates 52000 to cover layoff notices, paperwork morale etc. There are currently 75 experienced workers on staff