a)what is the bottleneck station(s)

b)what is the cycle time for this balance

c)what is the output rate in the front-end loaders per hour?

d)what is the efficiency of this balance?

e)Using this balance, how many hours per day would the line have to run the line in order to assemble 700 front-end loaders? Can the company meet demand with one shift?

f)If the assembly line wokers are paid $12 per hour for regular time (overtime is $18 per hour), what is the total average labor cost per front-end loader?

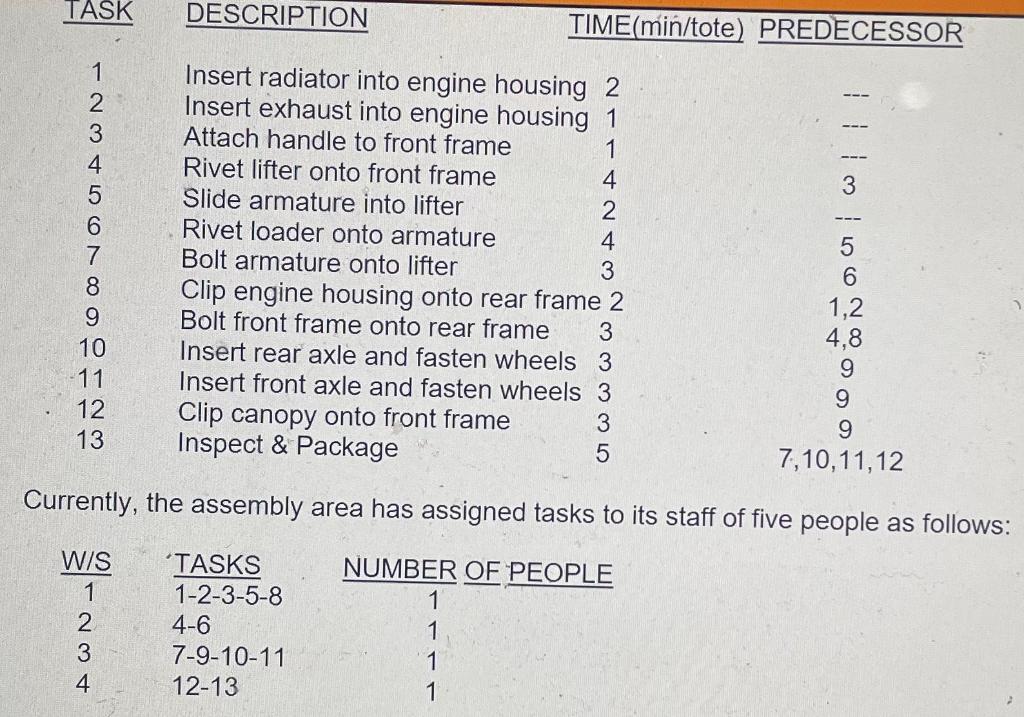

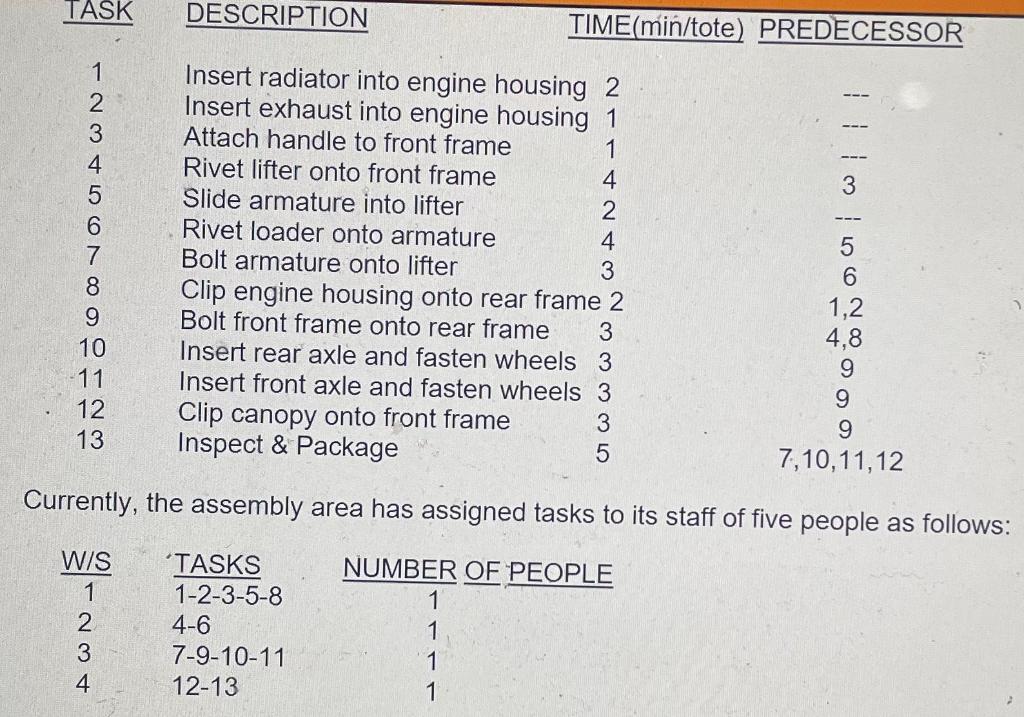

3. ACME Toys, Inc., a well-known manufacturer of toy trucks, cars, and construction equipment is studying the layout used for the final assembly of the front-end loaders - one of the company's most popular product lines. The problem is that the front-end loader's final assembly line is running almost eight hours per day and the company is concerned that the an to increase production to 700 units per day will require a second shift on this line. Of equal concern is the problem of reducing the cost of the front-end loader since, in recent years, competitors from abroad have been making inroads into the American market with cheaper versions of the company's products. The front-end loader gives rise to one of the more complicated assemblies of all the assemblies that the company performs. There are 13 tasks that must be performed along the final assembly line in order to finish the product. There is only enough equipment and space on the line for each task do be done by only one person. The standard times for these tasks are given in the table below. The positioning of these tasks along the line and the assignment of workers to these tasks has a significant impact on the capacity and efficiency of the line. The positioning of the tasks on the line determines the sequence of assembly steps in making the product. Because some assembly steps must necessarily precede other assembly steps, not every sequence is feasible. These necessities in the sequencing of tasks are represented as precedence constraints in the table below. Another constraint is results from the fact that there is only one riveting machine. The loader assemblies are transferred down the assembly line in kanban containers called "totes". Each tote carries parts for 10 front-end loaders. Each station on the line completes all 10 loaders in a tote before starting on the next tote. A TASK DESCRIPTION TIME(min/tote) PREDECESSOR 4 3 coop voor AWN- Insert radiator into engine housing 2 Insert exhaust into engine housing 1 Attach handle to front frame 1 Rivet lifter onto front frame Slide armature into lifter 2 Rivet loader onto armature 4 Bolt armature onto lifter 3 Clip engine housing onto rear frame 2 Bolt front frame onto rear frame 3 Insert rear axle and fasten wheels 3 Insert front axle and fasten wheels 3 Clip canopy onto front frame 3 Inspect & Package 5 10 11 5 6 1,2 4,8 9 9 9 7,10,11,12 13 Currently, the assembly area has assigned tasks to its staff of five people as follows: W/S 1 2 TASKS 1-2-3-5-8 4-6 7-9-10-11 12-13 NUMBER OF PEOPLE 1 1 A 1