Question: In this assignment you will re-solve the line balancing problem using the example presented in the text on p. 190. Assume the plant will be

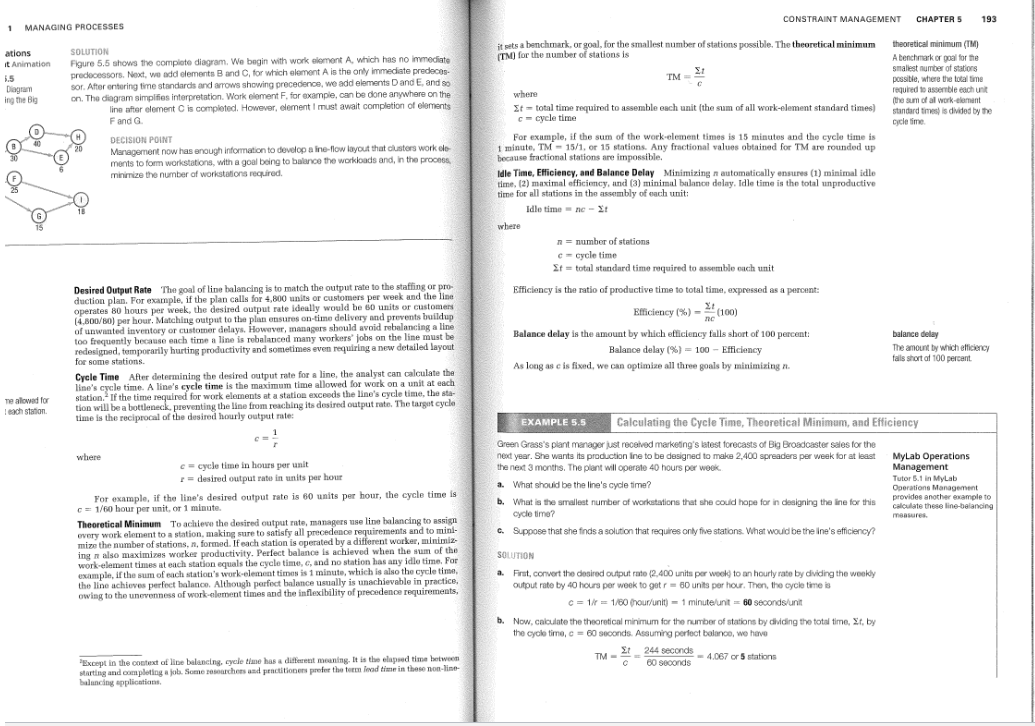

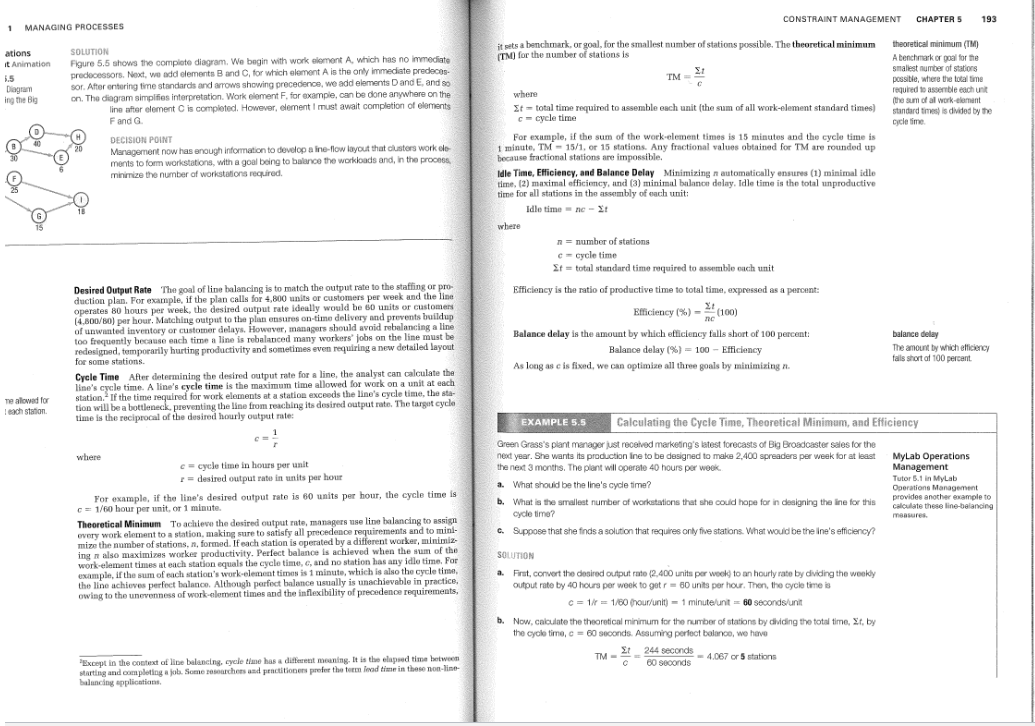

In this assignment you will re-solve the line balancing problem using the example presented in the text on p. 190. Assume the plant will be operating 80 hours per week (e.g. running two 40-hour shifts), but within that time the line is only operational on average about 85% of the time. In other words, rather than having 80 x 60 = 4800 minutes in which to produce the required 4800 units per week, (as in the video explanation), we really only have 80 x 60 x.85 = 4080 minutes in which to produce the required 4800 units per week. 1. Compute the target cycle time using this new information 2. Compute the theoretical minimum number of stations using this new target cycle time 3. Use the Longest Task Time procedure to balance the line using the new target cycle time. You should present your answer by listing the activities assigned to each station, in the order that they were assigned. 4. Compute the efficiency of the line using the actual cycle time resulting from the line balancing solution (as opposed to the target cycle time). 5. Why would it be important to incorporate this 85% "utilization factor" when we are solving the line balancing problem? CONSTRAINT MANAGEMENT CHAPTER 5 193 1 MANAGING PROCESSES ations it Animation 5.5 Diagram ing the Big SOLUTION Figure 5.5 shows the complete diagram. We begin with work element A, which has no immediate predecessors. Next, we add elements Band C, for which element is the only immediate predeces sor. After entering time standards and arrows showing precedence, we add elements and E, and so on. The diagram simplifies interpretation Work clement F, for example, can be done anywhere on the line after element is completed. However, clementi must await completion of elements Fand DECISION POINT Management now has enough information to develop a ine-llow layout that clusters workel ments to form workstations, with a goal being to balance the workloads and, in the proces minimize the number of workstations required it gets a benchmark, or goal, for the smallest number of stations possible. The theoretical minimum (TM) for the number of stations is TM-: where It - total time required to assemble each unit (the sum of all work-element standard times) cycle time theoretical minimum (TM) A benchmark or goal for the smallest number of stations possible, where the total time required to assemble cachunt (the sum of al work-element standard time is divided by the cycle time 15 For example, if the sum of the work-element times is 15 minutes and the cycle time is 1 minute, TM - 15/1, or 15 stations. Any fractional values obtained for TM are rounded up because fractional stations are impossible. Idle Time, Efficiency, and Balance Delay Minimizing automatically ensures (1) minimal idle time, (2) maximal efficiency, and (a) minimal balance delay. Idle time is the total unproductive time for all stations in the assembly of each unit: Idle timenet where n = number of stations c-cycle time St = total standard time required to assemble cach unit Efficiency is the ratio of productive time to total time, expressed as a percent: Efficiency (%) - (100) ne Balance delay is the amount by which efficiency falls short of 100 percent: : Balance delay (%) = 100 - Efficiency %= - As long as c is fixed, we can optimize all three goals by minimizing n. Desired Output Rate The goal of line balancing is to match the output rate to the staffing or pro duction plan. For example, if the plan calls for 4,800 units or customers per week and the line operates 80 hours per week, the desired output rate ideally would be 60 units or customers (4.800/80) per hour. Matching output to the plan ensures on-time delivery and prevents buildup of unwanted inventory or customer delays. However, managers should avoid rebalancing a line too frequently because each time a line is robalanced many workers' jobs on the line must be redesigned, temporarily hurting productivity and sometimes even requiring a new detailed layout for some stations. Cycle Time After determining the desired output rate for a line, the analyst can calculate the line's cycle time. A line's cycle time is the maximum time allowed for work on a unit at each station. If the time required for work elements at a station exceeds the line's cycle time, the sta tion will be a bottleneck, preventing the line from reaching its desired output rate. The target cycle time is the reciprocal of the desired hourly output rate balance delay The amount by which efficiency falls short of 100 percent Tealowed for I each station EXAMPLE 5.5 Calculating the Cycle Time, Theoretical Minimum, and Efficiency MyLab Operations Management Tutor 5.1 in MyLab Operations Management provides another example to calculate these line-balancing where C-cycle time in hours per unit r=desired output rate in units per hour For example, if the line's desired output rate is 60 units per hour, the cycle time is c = 1/60 hour per unit, or 1 minute Theoretical Minimum To achieve the desired output rate, managers te line balancing to assign every work element to a station, making sure to satisfy all precedence requirements and to mini- mize the number of stations, n, formed. If each station is operated by a different worker,minimi ing n also maximizes worker productivity. Perfect balance is achieved when the sum of the work-element times at each station equals the cycle time, and no station has any idle time. For example, if the sum of each station's work-element time is 1 minute, which is also the cycle time, the line achieves perfect balance. Although perfect balance usually is unachievable in practice. owing to the unevenness of work-element times and the inflexibility of precedence requirements, Green Grass's plant manager just received marketing's latest forecasts of Big Broadcaster sales for the next year. She wants its production line to be designed to make 2.400 spreaders per week for at least the next 3 months. The plant will operate 40 hours per week. a. What should be the line's cycle time? b. What is the smallest number of workstations that she could hope for in designing the line for this cycle time? c. Suppose that she finds a solution that requires only five stations. What would be the Ine's efficiency? a . SOLUTION First convert the desired output rato (2.400 units per week to an hourly rate by dividing the weekly output rate by 40 hours per week to get r = 50 units per hour. Then, the cycle time is c = 1/8 = 1/60 (hour/unit) 1 minute/unt = 60 seconds/unit b. Now, calculate the theoretical minimum for the number of stations by dividing the total time, t, by the cycle time, c = 60 seconds. Assuming perfect balance, we have 244 seconds TM - 4.067 or 5 stations 60 seconds Except in the context of le balancing, cycle time has a different meaning. It is the elapsed time between starting and completing a job. Some archers and penctitioners prefer the term load time in these non-line balancing applications In this assignment you will re-solve the line balancing problem using the example presented in the text on p. 190. Assume the plant will be operating 80 hours per week (e.g. running two 40-hour shifts), but within that time the line is only operational on average about 85% of the time. In other words, rather than having 80 x 60 = 4800 minutes in which to produce the required 4800 units per week, (as in the video explanation), we really only have 80 x 60 x.85 = 4080 minutes in which to produce the required 4800 units per week. 1. Compute the target cycle time using this new information 2. Compute the theoretical minimum number of stations using this new target cycle time 3. Use the Longest Task Time procedure to balance the line using the new target cycle time. You should present your answer by listing the activities assigned to each station, in the order that they were assigned. 4. Compute the efficiency of the line using the actual cycle time resulting from the line balancing solution (as opposed to the target cycle time). 5. Why would it be important to incorporate this 85% "utilization factor" when we are solving the line balancing problem? CONSTRAINT MANAGEMENT CHAPTER 5 193 1 MANAGING PROCESSES ations it Animation 5.5 Diagram ing the Big SOLUTION Figure 5.5 shows the complete diagram. We begin with work element A, which has no immediate predecessors. Next, we add elements Band C, for which element is the only immediate predeces sor. After entering time standards and arrows showing precedence, we add elements and E, and so on. The diagram simplifies interpretation Work clement F, for example, can be done anywhere on the line after element is completed. However, clementi must await completion of elements Fand DECISION POINT Management now has enough information to develop a ine-llow layout that clusters workel ments to form workstations, with a goal being to balance the workloads and, in the proces minimize the number of workstations required it gets a benchmark, or goal, for the smallest number of stations possible. The theoretical minimum (TM) for the number of stations is TM-: where It - total time required to assemble each unit (the sum of all work-element standard times) cycle time theoretical minimum (TM) A benchmark or goal for the smallest number of stations possible, where the total time required to assemble cachunt (the sum of al work-element standard time is divided by the cycle time 15 For example, if the sum of the work-element times is 15 minutes and the cycle time is 1 minute, TM - 15/1, or 15 stations. Any fractional values obtained for TM are rounded up because fractional stations are impossible. Idle Time, Efficiency, and Balance Delay Minimizing automatically ensures (1) minimal idle time, (2) maximal efficiency, and (a) minimal balance delay. Idle time is the total unproductive time for all stations in the assembly of each unit: Idle timenet where n = number of stations c-cycle time St = total standard time required to assemble cach unit Efficiency is the ratio of productive time to total time, expressed as a percent: Efficiency (%) - (100) ne Balance delay is the amount by which efficiency falls short of 100 percent: : Balance delay (%) = 100 - Efficiency %= - As long as c is fixed, we can optimize all three goals by minimizing n. Desired Output Rate The goal of line balancing is to match the output rate to the staffing or pro duction plan. For example, if the plan calls for 4,800 units or customers per week and the line operates 80 hours per week, the desired output rate ideally would be 60 units or customers (4.800/80) per hour. Matching output to the plan ensures on-time delivery and prevents buildup of unwanted inventory or customer delays. However, managers should avoid rebalancing a line too frequently because each time a line is robalanced many workers' jobs on the line must be redesigned, temporarily hurting productivity and sometimes even requiring a new detailed layout for some stations. Cycle Time After determining the desired output rate for a line, the analyst can calculate the line's cycle time. A line's cycle time is the maximum time allowed for work on a unit at each station. If the time required for work elements at a station exceeds the line's cycle time, the sta tion will be a bottleneck, preventing the line from reaching its desired output rate. The target cycle time is the reciprocal of the desired hourly output rate balance delay The amount by which efficiency falls short of 100 percent Tealowed for I each station EXAMPLE 5.5 Calculating the Cycle Time, Theoretical Minimum, and Efficiency MyLab Operations Management Tutor 5.1 in MyLab Operations Management provides another example to calculate these line-balancing where C-cycle time in hours per unit r=desired output rate in units per hour For example, if the line's desired output rate is 60 units per hour, the cycle time is c = 1/60 hour per unit, or 1 minute Theoretical Minimum To achieve the desired output rate, managers te line balancing to assign every work element to a station, making sure to satisfy all precedence requirements and to mini- mize the number of stations, n, formed. If each station is operated by a different worker,minimi ing n also maximizes worker productivity. Perfect balance is achieved when the sum of the work-element times at each station equals the cycle time, and no station has any idle time. For example, if the sum of each station's work-element time is 1 minute, which is also the cycle time, the line achieves perfect balance. Although perfect balance usually is unachievable in practice. owing to the unevenness of work-element times and the inflexibility of precedence requirements, Green Grass's plant manager just received marketing's latest forecasts of Big Broadcaster sales for the next year. She wants its production line to be designed to make 2.400 spreaders per week for at least the next 3 months. The plant will operate 40 hours per week. a. What should be the line's cycle time? b. What is the smallest number of workstations that she could hope for in designing the line for this cycle time? c. Suppose that she finds a solution that requires only five stations. What would be the Ine's efficiency? a . SOLUTION First convert the desired output rato (2.400 units per week to an hourly rate by dividing the weekly output rate by 40 hours per week to get r = 50 units per hour. Then, the cycle time is c = 1/8 = 1/60 (hour/unit) 1 minute/unt = 60 seconds/unit b. Now, calculate the theoretical minimum for the number of stations by dividing the total time, t, by the cycle time, c = 60 seconds. Assuming perfect balance, we have 244 seconds TM - 4.067 or 5 stations 60 seconds Except in the context of le balancing, cycle time has a different meaning. It is the elapsed time between starting and completing a job. Some archers and penctitioners prefer the term load time in these non-line balancing applications