Question: B. Batching / Process Interruptions Chapter 7 for Setups Everywhere (25 Points): Consider the following batch-flow process consisting of three process steps, with attrition loss

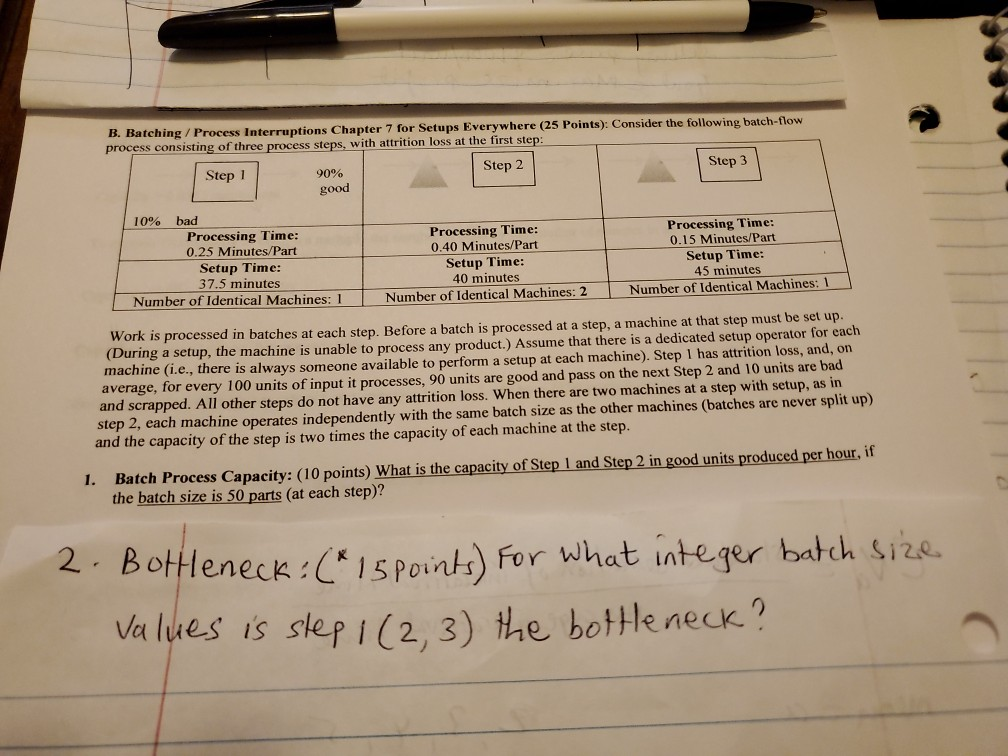

B. Batching / Process Interruptions Chapter 7 for Setups Everywhere (25 Points): Consider the following batch-flow process consisting of three process steps, with attrition loss at the first step: Step 1 90% Step 2 Step 3 good 10% bad Processing Time: 0.25 Minutes/Part Setup Time: 37.5 minutes Number of identical Machines: 1 Processing Time: 0.40 Minutes/Part Setup Time: 40 minutes Number of Identical Machines: 2 Processing Time: 0.15 Minutes/Part Setup Time: 45 minutes Number of Identical Machines: Work is processed in batches at each step. Before a batch is processed at a step, a machine at that step must be set up (During a setup, the machine is unable to process any product.) Assume that there is a dedicated setup operator for each machine (1.e., there is always someone available to perform a setup at each machine). Step 1 has attrition loss, and, on average, for every 100 units of input it processes, 90 units are good and pass on the next Step 2 and 10 units are bad and scrapped. All other steps do not have any attrition loss. When there are two machines at a step with setup, as in step 2, each machine operates independently with the same batch size as the other machines (batches are never split up) and the capacity of the step is two times the capacity of each machine at the step. 1. Batch Process Capacity: (10 points) What is the capacity of Step 1 and Step 2 in good units produced per hour, if the batch size is 50 parts at each step)? 2. Boffleneck (* 15 points for what integer batch size values is step 1 (2, 3) the bottleneck

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock