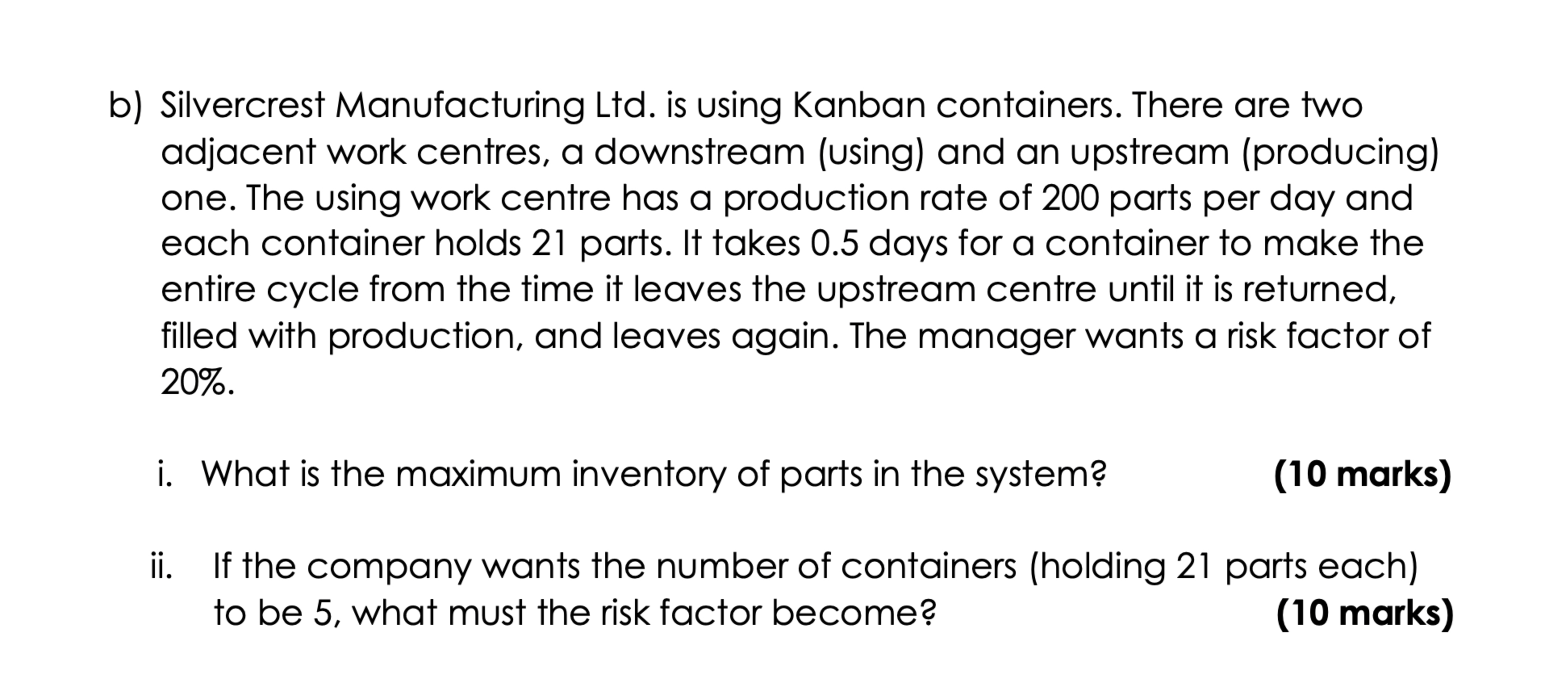

Question: b ) Silvercrest Manufacturing Ltd . is using Kanban containers. There are two adjacent work centres, a downstream ( using ) and an upstream (

b Silvercrest Manufacturing Ltd is using Kanban containers. There are two

adjacent work centres, a downstream using and an upstream producing

one. The using work centre has a production rate of parts per day and

each container holds parts. It takes days for a container to make the

entire cycle from the time it leaves the upstream centre until it is returned,

filled with production, and leaves again. The manager wants a risk factor of

i What is the maximum inventory of parts in the system?

marks

ii If the company wants the number of containers holding parts each

to be what must the risk factor become?

marks The following formula is used to calculate the number of bins for a given part

needed for a single Kanban loop between two cells in a production system:

Where:

Total number of bins for a given part.

Planned usage rate for the part parts per day

Average waiting time for replenishment of parts fraction of a day

Average production time for a container of parts fraction of a day

Capacity of the standard container number of parts

Risk factor set by management expressed as a decimal fraction

a At Schneider Electric Corp. the boxing station at the end of an electric switch

production line has a planned daily usage rate of switches per day

and receives the switches to be boxed from the preceding station in

containers which hold of the day's demand. It takes minutes for the

preceding station to fill a bin and minutes for the filled bin to be delivered to

the boxing station.

How many such bins are needed for the kanban loop to work efficiently in this

production cell, given a single hour shift per day and a risk factor of

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock