Question: Background: In your reading this week and in your assignment problems, you calculate measures of inventory, turns, days in supply, and average inventory. In a

Background:

In your reading this week and in your assignment problems, you calculate measures of inventory, turns, days in supply, and average inventory. In a simple sort of way, it would make sense that you would be sure to hold enough inventory so that you would never run out- to avoid having customers not being satisfied. In previous chapters, we have examined how inventory builds up between different processes and resources, ensuring things run smoothly at the activity and no labor is wasted. In systems where items are purchased, there are similar measures to ensure that inventory is there when it is needed.

However, the more inventory you hold, the more issues that potentially affect your firm.

Here are three examples of inventory failures:

Best Buy

Best Buys failure to manage its inventory was not only detrimental to sales, it also eroded the consumer trust that is central to any retailers success. With numerous articles with http://techcrunch.com/2011/12/23/how-best-buy-stole-christmas/ the negative publicity was overwhelming. According to Lee Resources Inc consultancy company, 91% of unhappy customers will not willingly do business with a company they had a bad experience with again. The nature of online business means that customers can move their business over to Amazon with the mere click of a button -which many did after this fiasco.Although Best Buy never released the details of what happened, its clear that information mismatch is to blame for Best Buys inability to deliver. Their solution of cancelling orders rather than delaying shipping seems to indicate that they oversold products that they didnt have in stock. Hello stockout! Its unlikely though that Best Buy would intentionally set out to disappoint their customers. However, the inability to deliver in the busiest season of the year directly plays into the narrative already on the minds of many consumers - that Best Buy could no longer adapt to market conditions, and that it was on its way down. The importance of a strong technological foundation cannot

be overstated in the management of an online business.

Walmart

With over 11,000 stores in 27 countries and an average of $32 billion in inventory, Walmarts supply chain is an

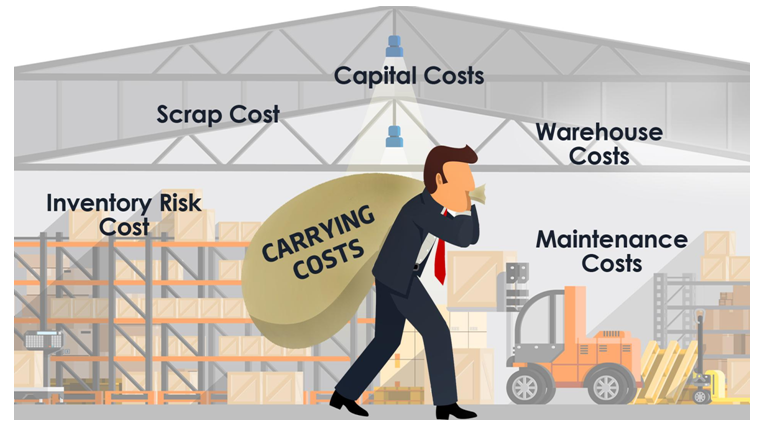

impressive logistical accomplishment. Nevertheless, Walmarts out-of-stock problem has been making waves in the recent years, periodically highlighted by both financial analysts and news channels including Forbes and Bloomberg. So, what went wrong? Analysts have attributed Walmarts problems to mismanaged inventory. In fact, one of the most important metrics for retailers is inventory turns - or the rate at which a retailer will cycle through its entire inventory. The faster the turn, the lower the cost, as helpfully outlined by this inventory holding

cost barometer infographic. Walmarts logistics are calculated down to incredible precision, from automatic resupply orders from Walmarts global head office to delivery trucks programmed to take the most efficient routes. Despite the meticulous detail that went into optimizing Walmarts processes from top down, many

shoppers were still not getting the experience that they expected from the retail giant.A customer interviewed by Bloomberg quite succinctly describes the problem: If its not on the shelf, I cant buy it. Walmart claims 90% to 95% in-stock level. Although this figure seems impressive, especially when taking into account the enormous size of its operations, it also means that the company could be foregoing $1.29 billion to $2.58

billion in potential sales (calculated as 5-10% of its inventory level of $25.8 billion on its 2012 annual report).

Walmarts logistics are calculated down to incredible precision, from automatic resupply orders from Walmarts

global head office to delivery trucks programmed to take the most efficient routes. Despite the meticulous detail that went into optimizing Walmarts processes from top down, many shoppers were still not getting the experience that they expected from the retail giant.A customer interviewed by Bloomberg quite succinctly

describes the problem: If its not on the shelf, I cant buy it. In fact, actual losses could be substantially greater - customers are much less likely to return to a store that continuously fails to restock products that they want.

Retail is a fiercely competitive industry, and with players such as Amazon gaining traction, mismanagement of

inventory could make or break a business virtually overnight. Walmart is famed for its extremely lean and technologically advanced supply chain, which makes the problem even more puzzling for onlookers. According to insiders, there were many cases where stock was available in storage, but due to shortage of staff, it got delayed for moving out to the shop floor. Customers gradually stopped shopping at Walmart because of bad service and empty shelves, and management cycle worsened the problem by further cutting back staff to save in costs. Hence, a vicious cycle. In this case, Walmart failed because they didnt anticipate and forecast the effect that their out-of-stock inventory level would have on the customer experience. In fact, a recent academic paper published by the Kenan-Flagler Business School suggests that a companys inventory management practices, good or bad, can predict the one-year ahead earnings for retailers.Even for giants like Walmart, inventory management remains the core of their business.

Nike

http://tradegecko.com/inventory-optimization/ is one of the biggest challenges merchants today are facing.

Nikes supply chain software implementation failure in 2001 is a cautionary tale for companies looking to implement complex systems without having the right resources in place. Nike installed its demand-planning software without sufficient testing, a necessary step for a company with such global and complex operations.

The result was excess stock of low selling shoes and not enough stock of the popular Air Jordans. According to a Nike press release, the mismatch directly resulted in a loss in sales of $100 million. Unlike the previous two examples, Nikes failure was a direct result of doing too much, too quickly. Technology can be transformational to a business when executed correctly. However, there is a tendency for businesses to misuse technology, and to cut costs without consideration for the potential effect it can have on business processes.

POST: Quickly review the 1-page thumbnail sketches of these three companies that illustrate inventory and supply chain failures and issues. From the list of Inventory Holding Costs from your reading in section 10.4.2 on page 309, POST two (2) different examples from the articles that illustrates clearly one of the four holding costs listed in the reading.

Be sure to 1) note the type of holding cost, and 2) how the article shows the difficulty or cost of holding inventory for that company. Be specific. Be sure you do this twice using different inventory holding costs.

Inventory Risk Capital Costs

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts