Question: Based on Table 5-14 Annual demand at CoolWipes and Table 5-15 Transportation costs per unit, without using Excel Solver, can you recommend in what cities

Based on Table 5-14 Annual demand at CoolWipes and Table 5-15 Transportation costs per unit, without using Excel Solver, can you recommend in what cities should the new plant(s) be built for wipes or ointment? Please explain your reasons. Please answer this question, not the study questions below.

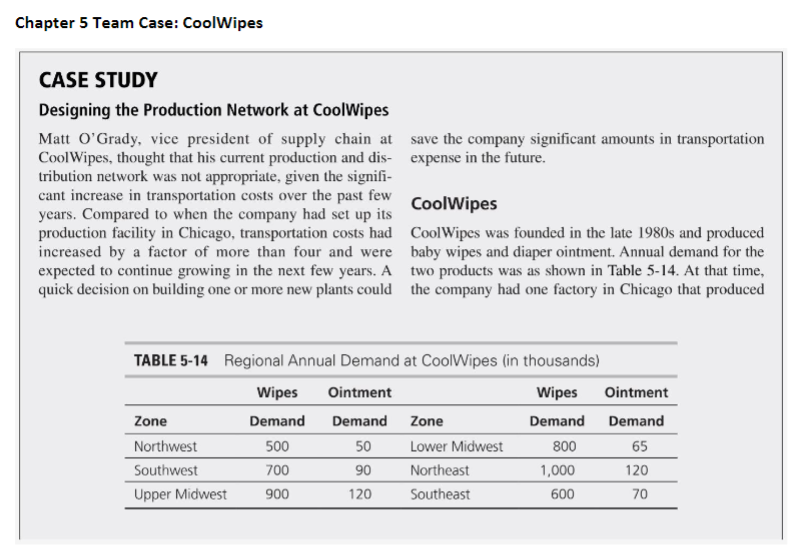

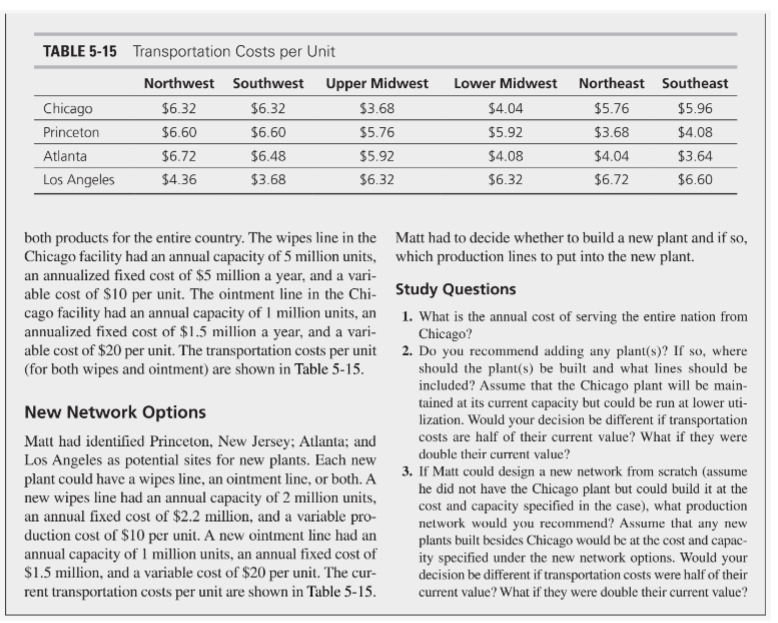

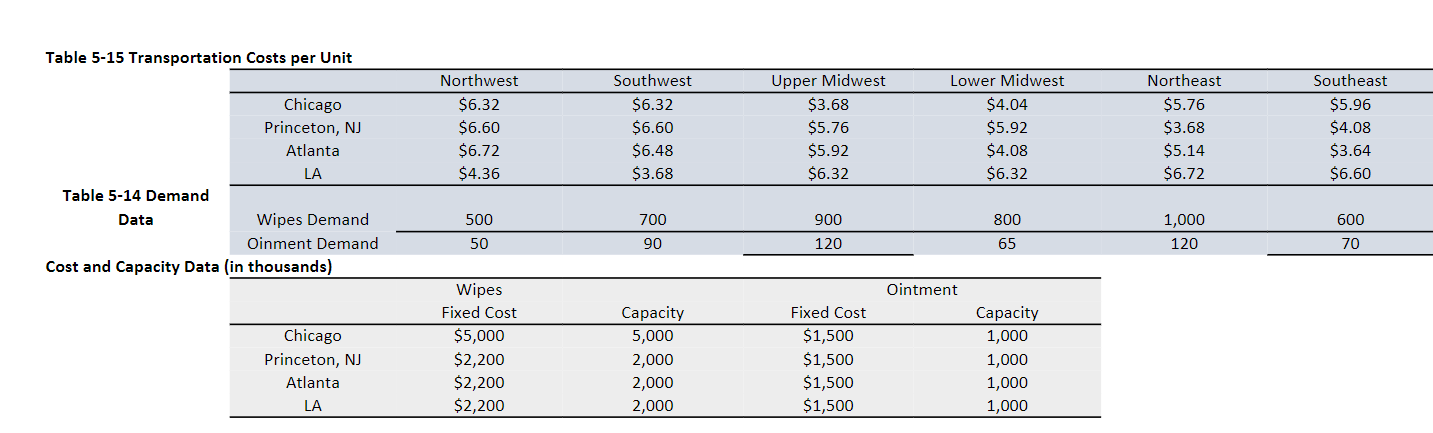

CASE STUDY Designing the Production Network at CoolWipes Matt O'Grady, vice president of supply chain at save the company significant amounts in transportation CoolWipes, thought that his current production and dis- expense in the future. tribution network was not appropriate, given the significant increase in transportation costs over the past few years. Compared to when the company had set up its production facility in Chicago, transportation costs had CoolWipes was founded in the late 1980s and produced increased by a factor of more than four and were baby wipes and diaper ointment. Annual demand for the expected to continue growing in the next few years. A two products was as shown in Table 5-14. At that time, quick decision on building one or more new plants could the company had one factory in Chicago that produced both products for the entire country. The wipes line in the Matt had to decide whether to build a new plant and if so, Chicago facility had an annual capacity of 5 million units, which production lines to put into the new plant. an annualized fixed cost of $5 million a year, and a variable cost of $10 per unit. The ointment line in the ChiStudy Questions cago facility had an annual capacity of 1 million units, an 1. What is the annual cost of serving the entire nation from annualized fixed cost of $1.5 million a year, and a variChicago? able cost of $20 per unit. The transportation costs per unit 2. Do you recommend adding any plant(s)? If so, where (for both wipes and ointment) are shown in Table 5-15. should the plant(s) be built and what lines should be included? Assume that the Chicago plant will be main- New Network Options tained at its current capacity but could be run at lower utiLos Angeles as potential sites for new plants. Each new plant could have a wipes line, an ointment line, or both. A costs are half of their current value? What if they were double their current value? new wipes line had an annual capacity of 2 million units, 3. If Matt could design a new network from scratch (assume an annual fixed cost of $2.2 million, and a variable pro- cost and capacity specified in the case), what production duction cost of $10 per unit. A new ointment line had an network would you recommend? Assume that any new annual capacity of 1 million units, an annual fixed cost of plants built besides Chicago would be at the cost and capacrent transportation costs per unit are shown in Table 5-15. current value? What if they were double their current value? Table 5-15 Transportation Costs per Unit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts