Question: Based on the below data for the present state and future state, for the crank shaft production line, draw the value stream map that depicts

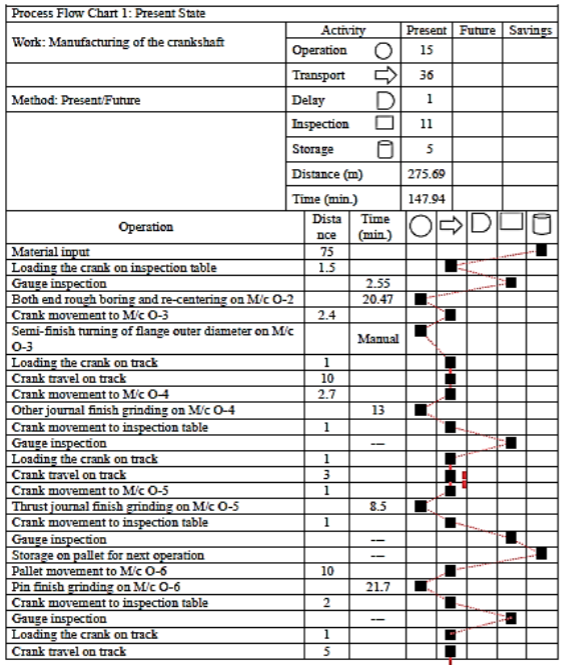

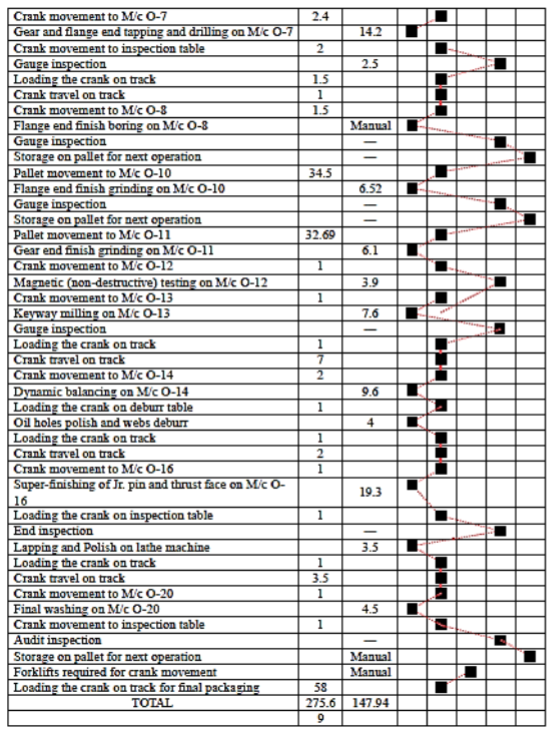

Based on the below data for the present state and future state, for the crank shaft production line, draw the value stream map that depicts the present state. Highlight points on your map that indicate the type of waste.

(There are 21 operations on the flow chart, only the most important operations will be translated into the value stream map. The black squares on the flow represent each activity the present state is going through. There are 8 different types of waste. Suggest what type of waste is involved with each step in the process. The suggestions should represent the future state on the value stream map)

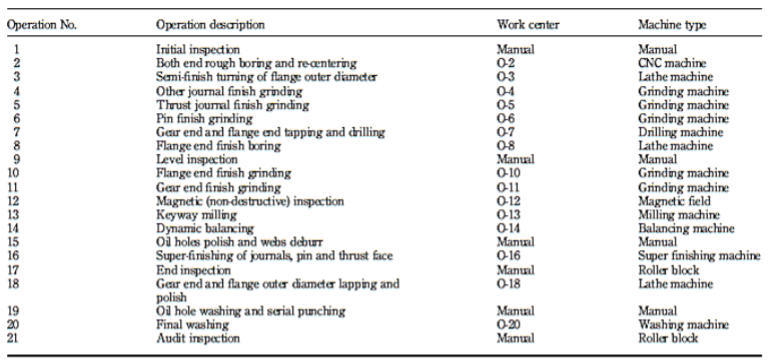

Sequence of operations

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts