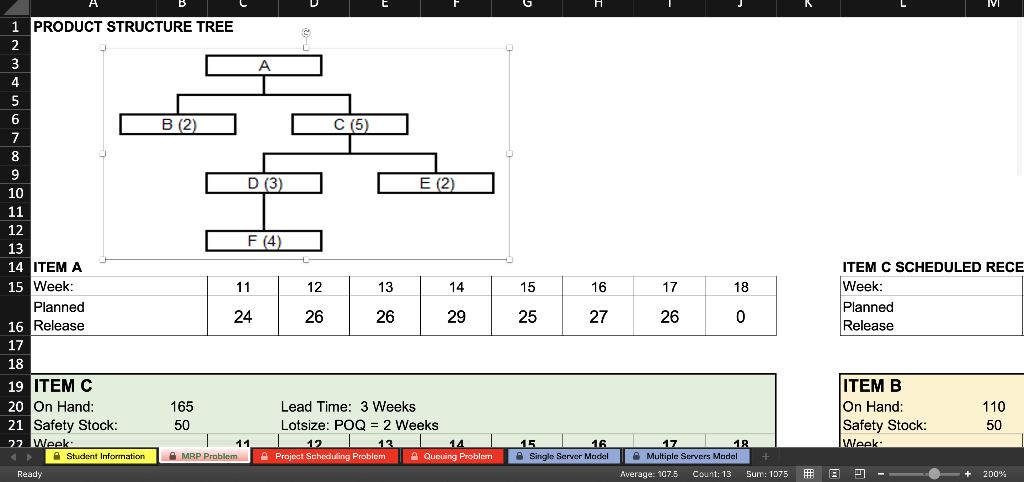

Question: Based on the information provided, what are the current Planned Releases for Product A for weeks 11-18. Enter these into cells C16-J16 on the MRP

Based on the information provided, what are the current Planned Releases for Product A for weeks 11-18. Enter these into cells C16-J16 on the MRP Problem tab of your workbook.

In addition to filling in the complete row in the Excel spreadsheet, enter the two values requested below:

Planned Releases for Item A in week 11:

Planned Releases for Item A in week 12:

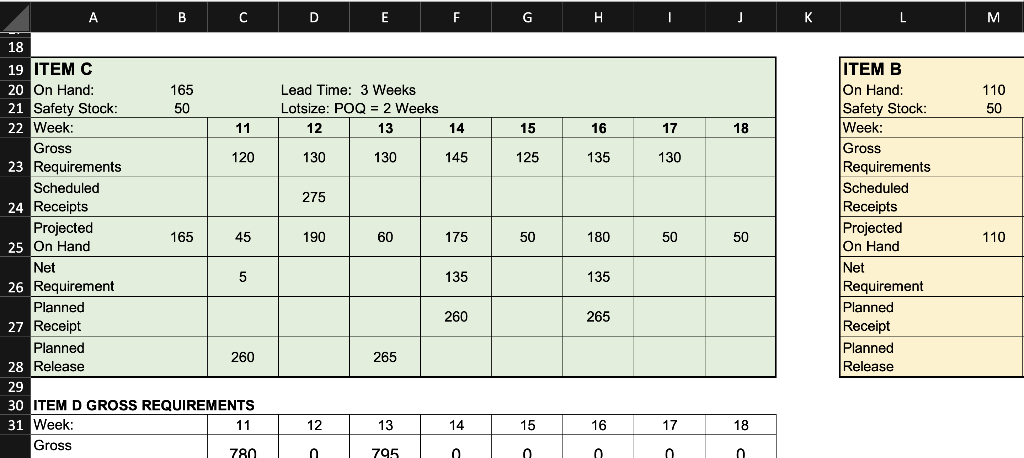

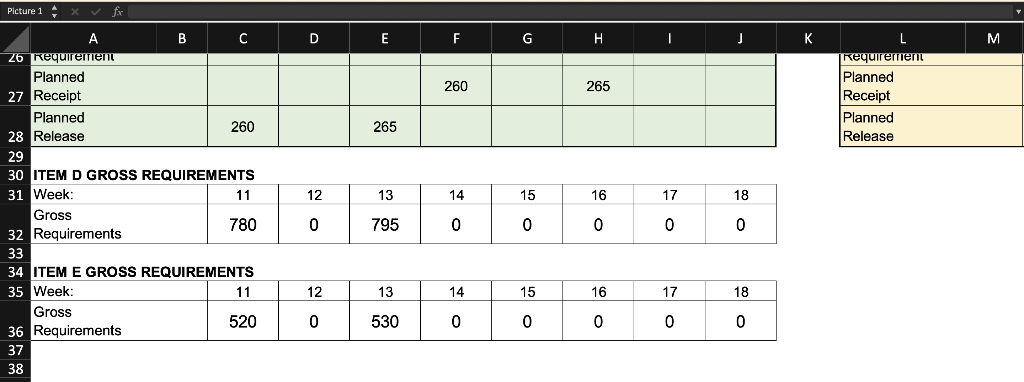

Based on the information provided, what are the current Gross Requirements for Item D for weeks 11-18. Enter these into cells C32-J32 on the MRP Problem tab of your workbook.

In addition to filling in the complete row in the Excel spreadsheet, enter the two values requested below:

Item D Gross Requirements for Week 11:

Item D Gross Requirements for Week 12 :

Based on the information provided, what are the current Gross Requirements for Item E for weeks 11-18. Enter these into cells C36-J36 on the MRP Problem tab of your workbook.

In addition to filling in the complete row in the Excel spreadsheet, enter the two values requested below:

Item E Gross Requirements for Week 11 :

Item E Gross Requirements for Week 12 :

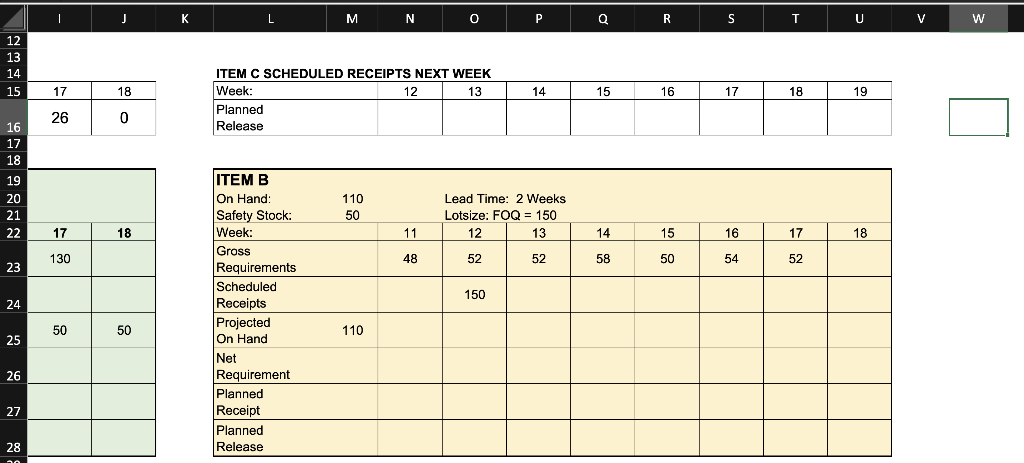

Based on the information provided, what will we be seeing next week in the Scheduled Receipt row, when we come back and complete the Item C MRP table covering weeks 12-19. Enter these into the cells N16-U16 on the MRP Problem tab of your workbook.

In addition to filling in the complete row in the Excel spreadsheet, enter the two values requested below:

Item C Scheduled Receipts for week 12, in the week 12-19 MRP table:

Item C Scheduled Receipts for week 13, in the week 12-19 MRP table:

*I entered what I though the answers were... may be wrong though*

IVI D (3) A 1 PRODUCT STRUCTURE TREE 2 3 A 4 5 6 B (2) C (5) 7 8 9 E (2) 10 11 12 13 14 ITEM A 15 Week: 11 12 13 14 Planned 24 26 26 29 16 Release 17 18 19 ITEMC 20 On Hand: 165 Lead Time: 3 Weeks 21 Safety Stock: 50 Lotsize: POQ = 2 Weeks 22 Week 11 12 13 14 Student Information MRP Problem Project Scheduling Problem Queuing Problem Ready F (4) 15 16 17 18 ITEM C SCHEDULED RECE Week: Planned Release 25 27 26 0 ITEM B On Hand: Safety Stock: Week 110 50 15 16 - Single Server Madel 17 18 Multiple Servers Model Average: 107.5 Count: 13 Sum: 1075 200% A B D E H M Lead Time: 3 Weeks Lotsize: POQ = 2 Weeks 12 13 110 50 14 15 16 17 18 130 130 145 125 135 130 275 ITEM B On Hand: Safety Stock: Week: Gross Requirements Scheduled Receipts Projected On Hand Net Requirement Planned Receipt Planned Release 190 60 175 50 180 50 50 18 19 ITEM C 20 On Hand: 165 21 Safety Stock: 50 22 Week: 11 Gross 120 23 Requirements Scheduled 24 Receipts Projected 165 45 25 On Hand Net 5 26 Requirement Planned 27 Receipt Planned 260 28 Release 29 30 ITEM D GROSS REQUIREMENTS 31 Week: 11 Gross 780 110 135 135 260 265 265 12 13 14 15 16 17 18 n 795 0 Picture 1 Xfx D E F G . T J M 260 265 L Requirement Planned Receipt Planned Release 265 12 13 14 15 16 17 18 A B C 26 Requirement Planned 27 Receipt Planned 260 28 Release 29 30 ITEM D GROSS REQUIREMENTS 31 Week: 11 Gross 32 Requirements 780 33 34 ITEM E GROSS REQUIREMENTS 35 Week: 11 Gross 520 36 Requirements 37 38 0 795 0 0 0 0 0 12 13 14 15 16 17 18 0 530 0 0 0 0 0 | J K L M N 0 P Q R S T. U V W 12 13 14 15 17 18 14 15 16 17 18 19 ITEM C SCHEDULED RECEIPTS NEXT WEEK Week: 12 13 Planned Release 26 0 16 17 18 19 20 21 22 110 50 Lead Time: 2 Weeks Lotsize: FOQ = 150 12 13 17 18 11 14 15 16 17 18 130 48 52 52 58 50 54 52 23 150 24 ITEM B On Hand: Safety Stock: Week: Gross Requirements Scheduled Receipts Projected On Hand Net Requirement Planned Receipt Planned Release 50 50 110 25 26 27 28 20 IVI D (3) A 1 PRODUCT STRUCTURE TREE 2 3 A 4 5 6 B (2) C (5) 7 8 9 E (2) 10 11 12 13 14 ITEM A 15 Week: 11 12 13 14 Planned 24 26 26 29 16 Release 17 18 19 ITEMC 20 On Hand: 165 Lead Time: 3 Weeks 21 Safety Stock: 50 Lotsize: POQ = 2 Weeks 22 Week 11 12 13 14 Student Information MRP Problem Project Scheduling Problem Queuing Problem Ready F (4) 15 16 17 18 ITEM C SCHEDULED RECE Week: Planned Release 25 27 26 0 ITEM B On Hand: Safety Stock: Week 110 50 15 16 - Single Server Madel 17 18 Multiple Servers Model Average: 107.5 Count: 13 Sum: 1075 200% A B D E H M Lead Time: 3 Weeks Lotsize: POQ = 2 Weeks 12 13 110 50 14 15 16 17 18 130 130 145 125 135 130 275 ITEM B On Hand: Safety Stock: Week: Gross Requirements Scheduled Receipts Projected On Hand Net Requirement Planned Receipt Planned Release 190 60 175 50 180 50 50 18 19 ITEM C 20 On Hand: 165 21 Safety Stock: 50 22 Week: 11 Gross 120 23 Requirements Scheduled 24 Receipts Projected 165 45 25 On Hand Net 5 26 Requirement Planned 27 Receipt Planned 260 28 Release 29 30 ITEM D GROSS REQUIREMENTS 31 Week: 11 Gross 780 110 135 135 260 265 265 12 13 14 15 16 17 18 n 795 0 Picture 1 Xfx D E F G . T J M 260 265 L Requirement Planned Receipt Planned Release 265 12 13 14 15 16 17 18 A B C 26 Requirement Planned 27 Receipt Planned 260 28 Release 29 30 ITEM D GROSS REQUIREMENTS 31 Week: 11 Gross 32 Requirements 780 33 34 ITEM E GROSS REQUIREMENTS 35 Week: 11 Gross 520 36 Requirements 37 38 0 795 0 0 0 0 0 12 13 14 15 16 17 18 0 530 0 0 0 0 0 | J K L M N 0 P Q R S T. U V W 12 13 14 15 17 18 14 15 16 17 18 19 ITEM C SCHEDULED RECEIPTS NEXT WEEK Week: 12 13 Planned Release 26 0 16 17 18 19 20 21 22 110 50 Lead Time: 2 Weeks Lotsize: FOQ = 150 12 13 17 18 11 14 15 16 17 18 130 48 52 52 58 50 54 52 23 150 24 ITEM B On Hand: Safety Stock: Week: Gross Requirements Scheduled Receipts Projected On Hand Net Requirement Planned Receipt Planned Release 50 50 110 25 26 27 28 20Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts