Question: based on their cookie booth concept, they were awarded a contract by girl scouts usa to be the sole provider of cookie booth kits. The

based on their cookie booth concept, they were awarded a contract by girl scouts usa to be the sole provider of cookie booth kits.

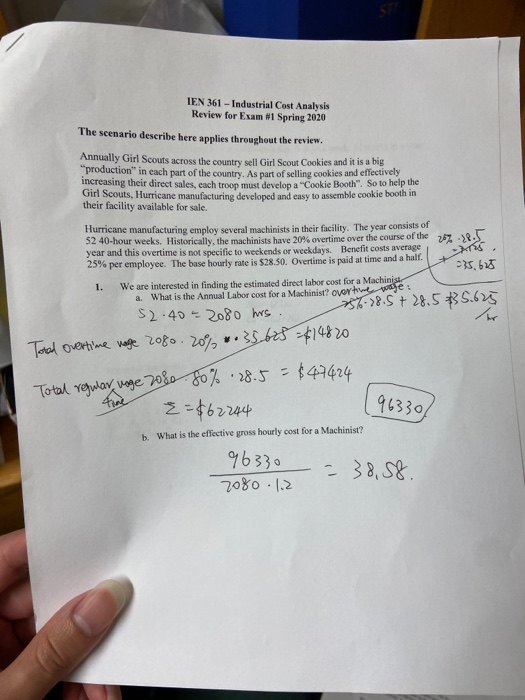

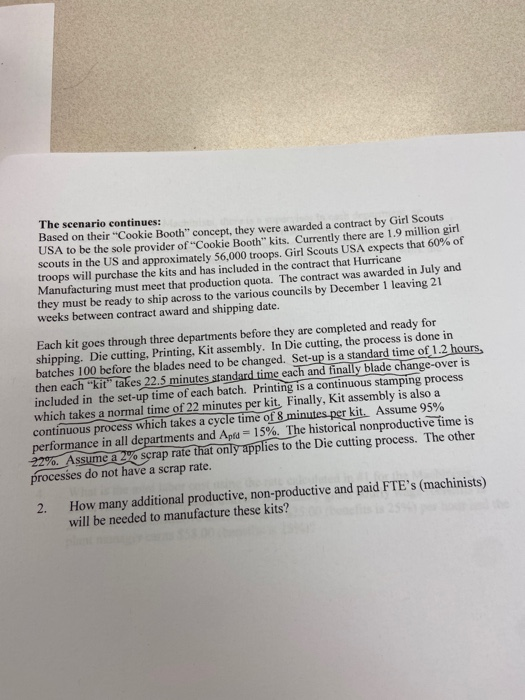

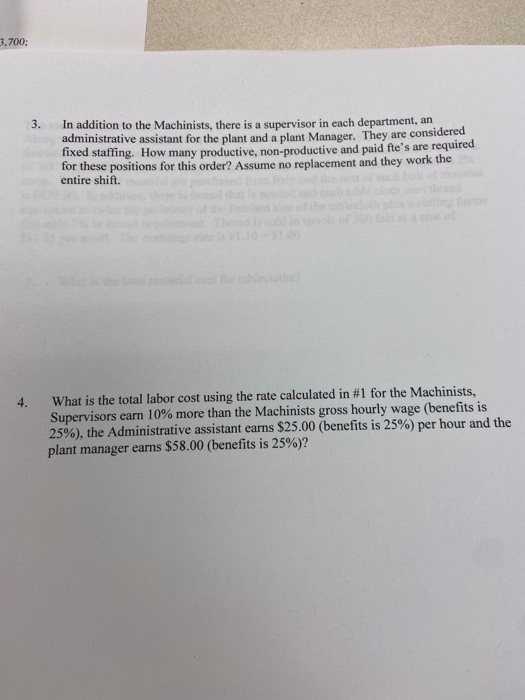

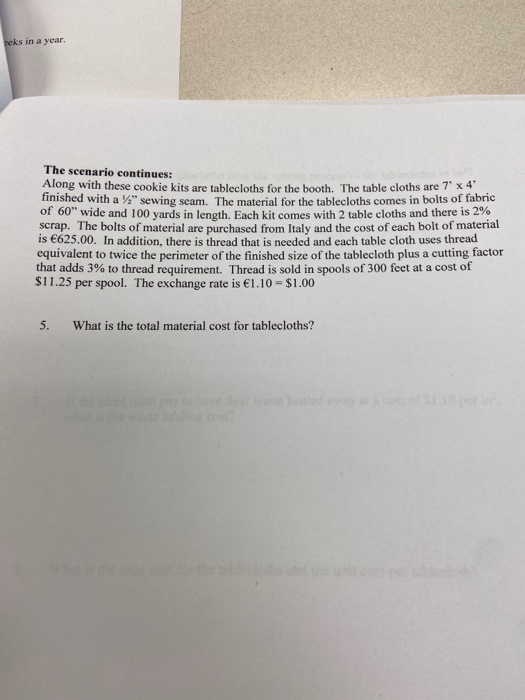

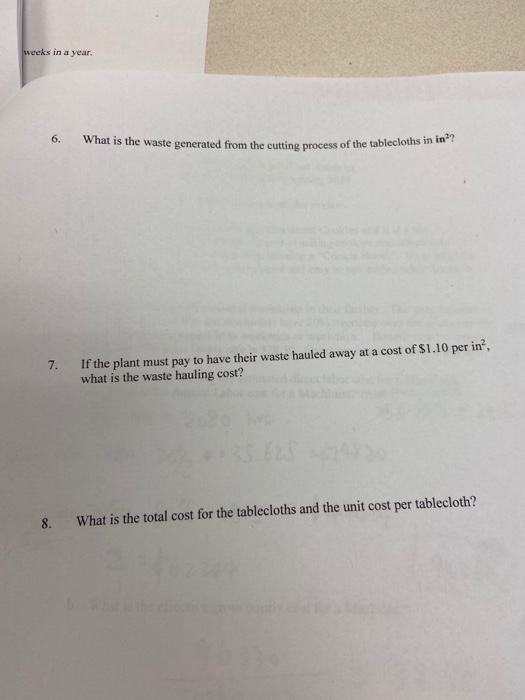

The scenario continues: Based on their "Cookie Booth" concept, they were awarded a contract by Girl Scouts USA to be the sole provider of "Cookie Booth" kits. Currently there are 1.9 million girl scouts in the US and approximately 56,000 troops. Girl Scouts USA expects that 60% of troops will purchase the kits and has included in the contract that Hurricane Manufacturing must meet that production quota. The contract was awarded in July and they must be ready to ship across to the various councils by December 1 leaving 21 weeks between contract award and shipping date. Each kit goes through three departments before they are completed and ready for shipping. Die cutting, Printing, Kit assembly. In Die cutting, the process is done in batches 100 before the blades need to be changed. Set-up is a standard time of 1.2 hours, then each "kit" takes 22.5 minutes standard time each and finally blade change-over is included in the set-up time of each batch. Printing is a continuous stamping process which takes a normal time of 22 minutes per kit. Finally, Kit assembly is als continuous process which takes a cycle time of 8 minutes per kit. Assume 95% performance in all departments and Apfd = 15%. The historical nonproductive time is 22%. Assume a 2% scrap rate that only applies to the Die cutting process. The other processes do not have a scrap rate. 2. How many additional productive, non-productive and paid FTE's (machinists) will be needed to manufacture these kits? 3.700; 3. In addition to the Machinists, there is a supervisor in each department, an administrative assistant for the plant and a plant Manager. They are considered fixed staffing. How many productive, non-productive and paid fte's are required for these positions for this order? Assume no replacement and they work the entire shift. 4. What is the total labor cost using the rate calculated in #1 for the Machinists, Supervisors earn 10% more than the Machinists gross hourly wage (benefits is 25%), the Administrative assistant earns $25.00 (benefits is 25%) per hour and the plant manager earns $58.00 (benefits is 25%)? reks in a year. The scenario continues: Along with these cookie kits are tablecloths for the booth. The table cloths are 7 x4 finished with a sewing seam. The material for the tablecloths comes in bolts of fabric of 60" wide and 100 yards in length. Each kit comes with 2 table cloths and there is 2% scrap. The bolts of material are purchased from Italy and the cost of each bolt of material is 625.00. In addition, there is thread that is needed and each table cloth uses thread equivalent to twice the perimeter of the finished size of the tablecloth plus a cutting factor that adds 3% to thread requirement. Thread is sold in spools of 300 feet at a cost of $11.25 per spool. The exchange rate is 1.10 = $1.00 5. What is the total material cost for tablecloths? weeks in a year. 0. What is the waste generated from the cutting process of the tablecloths 7. If the plant must pay to have their waste hauled away at a cost of $1.10 per in, what is the waste hauling cost? 8. What is the total cost for the tablecloths and the unit cost per tablecloth? IEN 361 - Industrial Cost Analysis Review for Exam #1 Spring 2020 The scenario describe here applies throughout the review. Annually Girl Scouts across the country sell Girl Scout Cookies and it is a big production in each part of the country. As part of selling cookies and effectively increasing their direct sales ench tro must develop a Cookie Booth". So to help the Girl Scouts, Hurricane manufacturing developed and easy to assemble cookie booth in their facility available for sale. Hurricane manufacturing employ several machinists in their facility. The year consists of 52 40 hour weeks. Historically, the machinists have 20% overtime over the course of the 22 . year and this overtime is not specific to weekends or weekdays. Benefit costs average s 25% per employee. The base hourly rate is $28.50. Overtime is paid at time and a half =35,625 1. We are interested in finding the estimated direct labor cost for a Machinist a. What is the Annual Labor cost for a Machinist? Overhvewage 52.40-2080 hrs. 75%->8.5+ 28.5*5.675 hr Total Overtime nage 2080.20% .35625 - $14820 Total regular wage 2080 80% 28.5 = $47424 Time E = $62244 196330 b. What is the effective gross hourly cost for a Machinist? 96330 . 3858. 2080.12 The scenario continues: Based on their "Cookie Booth" concept, they were awarded a contract by Girl Scouts USA to be the sole provider of "Cookie Booth" kits. Currently there are 1.9 million girl scouts in the US and approximately 56,000 troops. Girl Scouts USA expects that 60% of troops will purchase the kits and has included in the contract that Hurricane Manufacturing must meet that production quota. The contract was awarded in July and they must be ready to ship across to the various councils by December 1 leaving 21 weeks between contract award and shipping date. Each kit goes through three departments before they are completed and ready for shipping. Die cutting, Printing, Kit assembly. In Die cutting, the process is done in batches 100 before the blades need to be changed. Set-up is a standard time of 1.2 hours, then each "kit" takes 22.5 minutes standard time each and finally blade change-over is included in the set-up time of each batch. Printing is a continuous stamping process which takes a normal time of 22 minutes per kit. Finally, Kit assembly is als continuous process which takes a cycle time of 8 minutes per kit. Assume 95% performance in all departments and Apfd = 15%. The historical nonproductive time is 22%. Assume a 2% scrap rate that only applies to the Die cutting process. The other processes do not have a scrap rate. 2. How many additional productive, non-productive and paid FTE's (machinists) will be needed to manufacture these kits? 3.700; 3. In addition to the Machinists, there is a supervisor in each department, an administrative assistant for the plant and a plant Manager. They are considered fixed staffing. How many productive, non-productive and paid fte's are required for these positions for this order? Assume no replacement and they work the entire shift. 4. What is the total labor cost using the rate calculated in #1 for the Machinists, Supervisors earn 10% more than the Machinists gross hourly wage (benefits is 25%), the Administrative assistant earns $25.00 (benefits is 25%) per hour and the plant manager earns $58.00 (benefits is 25%)? reks in a year. The scenario continues: Along with these cookie kits are tablecloths for the booth. The table cloths are 7 x4 finished with a sewing seam. The material for the tablecloths comes in bolts of fabric of 60" wide and 100 yards in length. Each kit comes with 2 table cloths and there is 2% scrap. The bolts of material are purchased from Italy and the cost of each bolt of material is 625.00. In addition, there is thread that is needed and each table cloth uses thread equivalent to twice the perimeter of the finished size of the tablecloth plus a cutting factor that adds 3% to thread requirement. Thread is sold in spools of 300 feet at a cost of $11.25 per spool. The exchange rate is 1.10 = $1.00 5. What is the total material cost for tablecloths? weeks in a year. 0. What is the waste generated from the cutting process of the tablecloths 7. If the plant must pay to have their waste hauled away at a cost of $1.10 per in, what is the waste hauling cost? 8. What is the total cost for the tablecloths and the unit cost per tablecloth? IEN 361 - Industrial Cost Analysis Review for Exam #1 Spring 2020 The scenario describe here applies throughout the review. Annually Girl Scouts across the country sell Girl Scout Cookies and it is a big production in each part of the country. As part of selling cookies and effectively increasing their direct sales ench tro must develop a Cookie Booth". So to help the Girl Scouts, Hurricane manufacturing developed and easy to assemble cookie booth in their facility available for sale. Hurricane manufacturing employ several machinists in their facility. The year consists of 52 40 hour weeks. Historically, the machinists have 20% overtime over the course of the 22 . year and this overtime is not specific to weekends or weekdays. Benefit costs average s 25% per employee. The base hourly rate is $28.50. Overtime is paid at time and a half =35,625 1. We are interested in finding the estimated direct labor cost for a Machinist a. What is the Annual Labor cost for a Machinist? Overhvewage 52.40-2080 hrs. 75%->8.5+ 28.5*5.675 hr Total Overtime nage 2080.20% .35625 - $14820 Total regular wage 2080 80% 28.5 = $47424 Time E = $62244 196330 b. What is the effective gross hourly cost for a Machinist? 96330 . 3858. 2080.12