Question: Based on this article: How would you characterize large home appliances, such as refrigerators, washing machines, and dryers (in terms of product type)? Why? Assume

Based on this article:

- How would you characterize large home appliances, such as refrigerators, washing machines, and dryers (in terms of product type)? Why?

- Assume that you are the Operations Manager for a large home appliances factory, what are some of the manufacturing decisions you would make in terms supply chain levers such as inventory strategy, and other parameters such as batch sizes, lead time, etc.? Why?

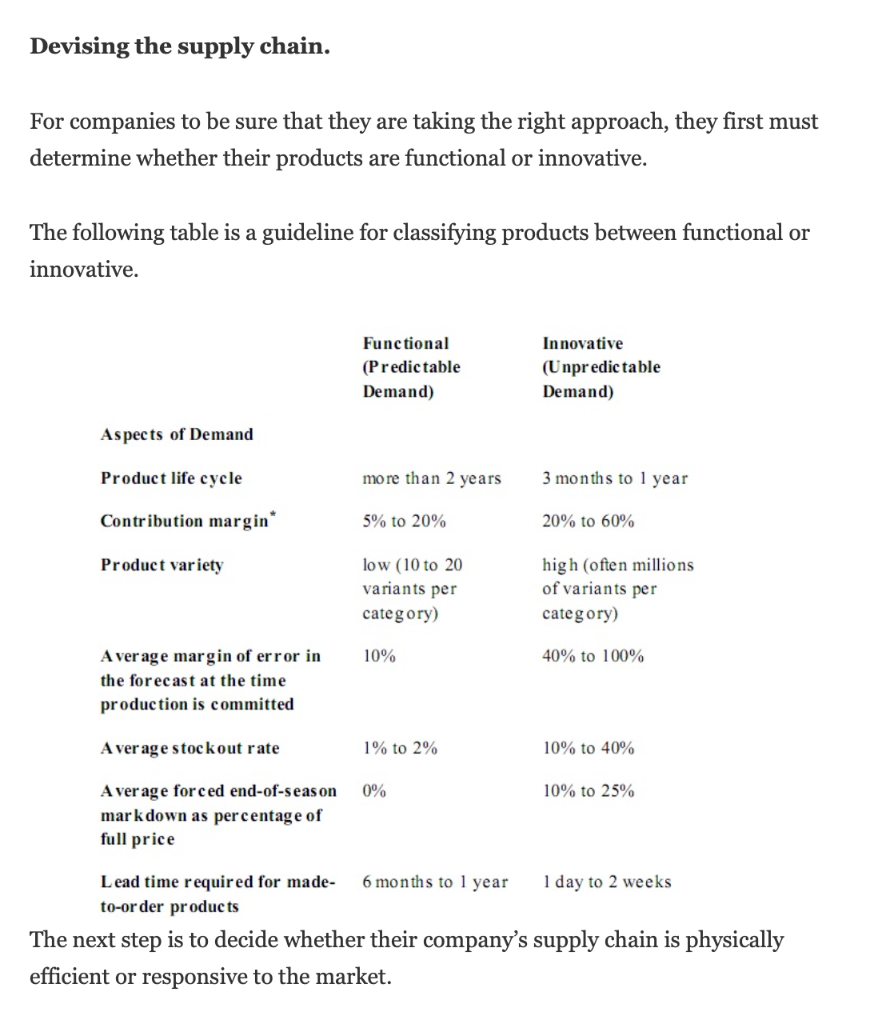

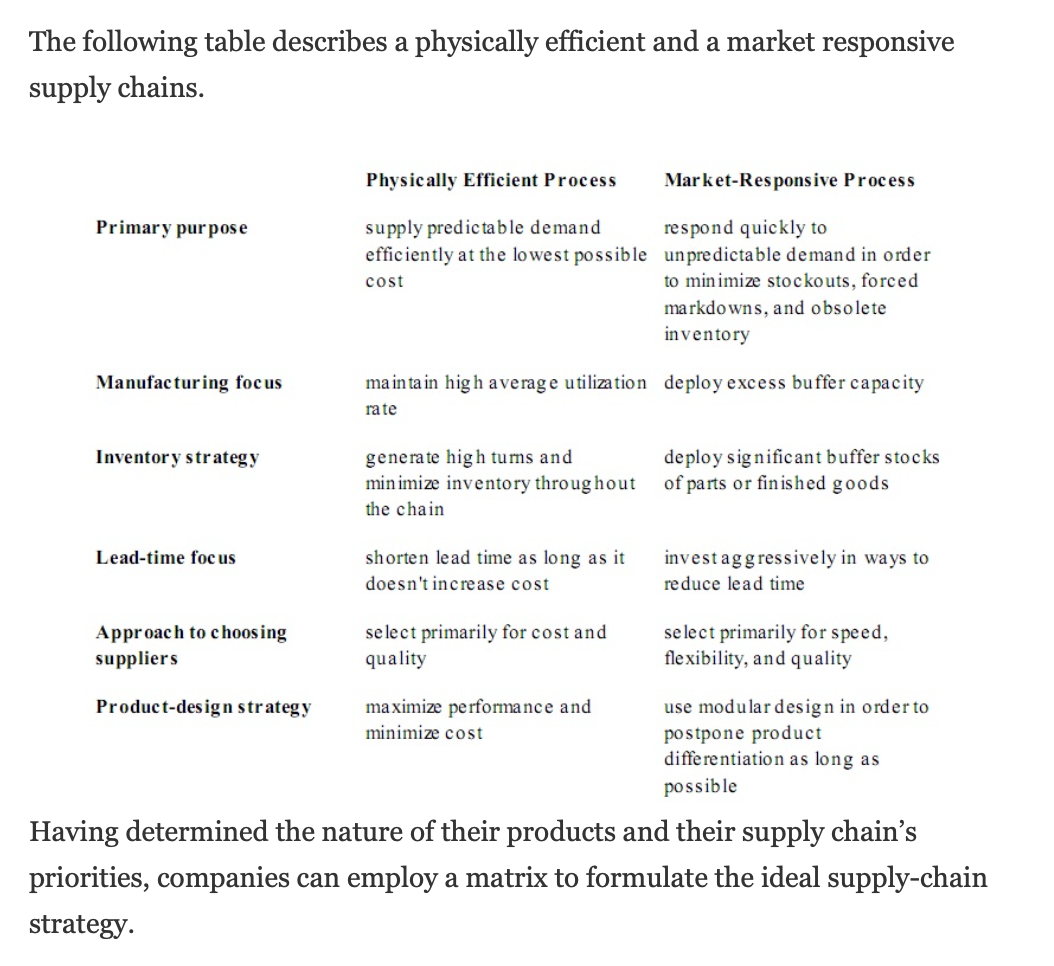

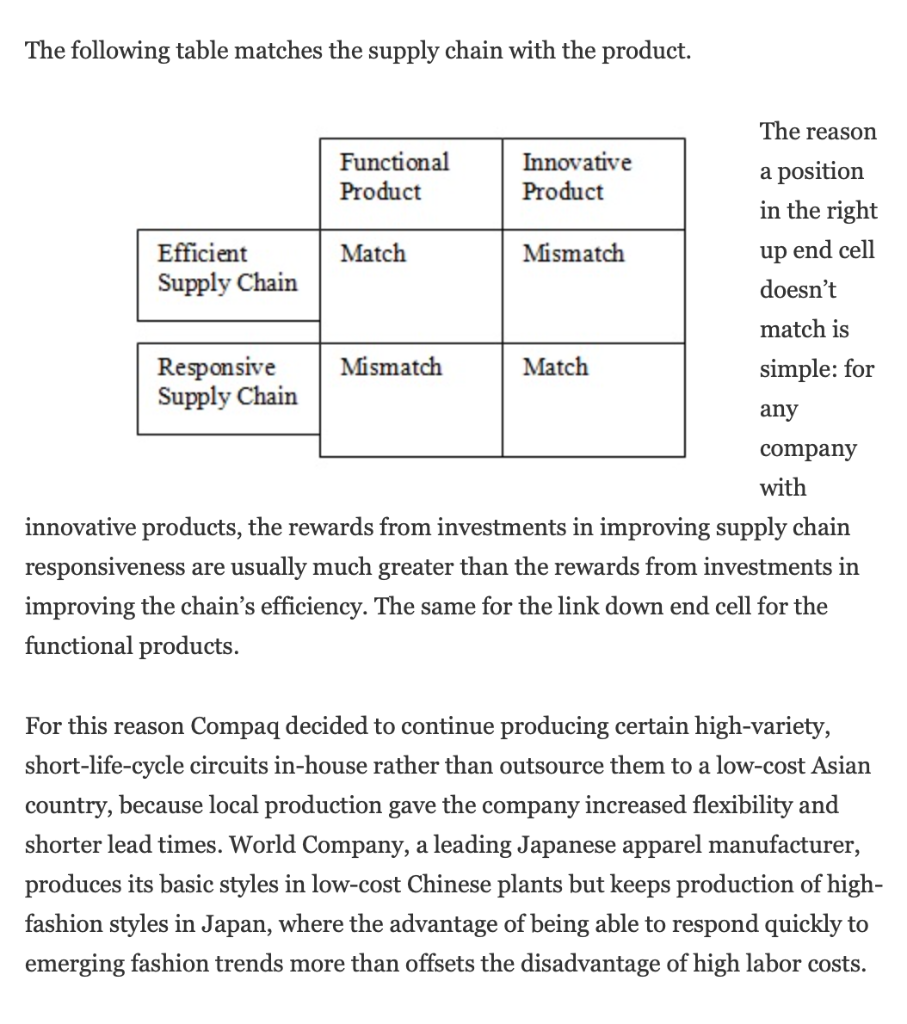

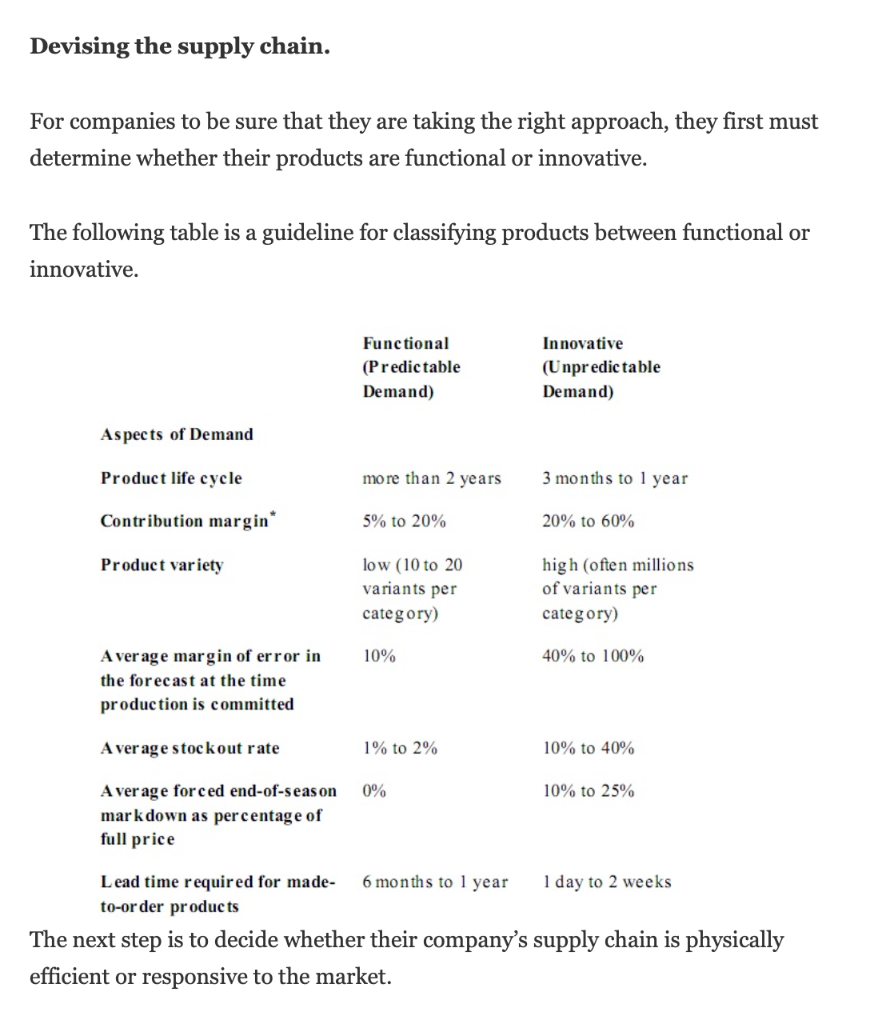

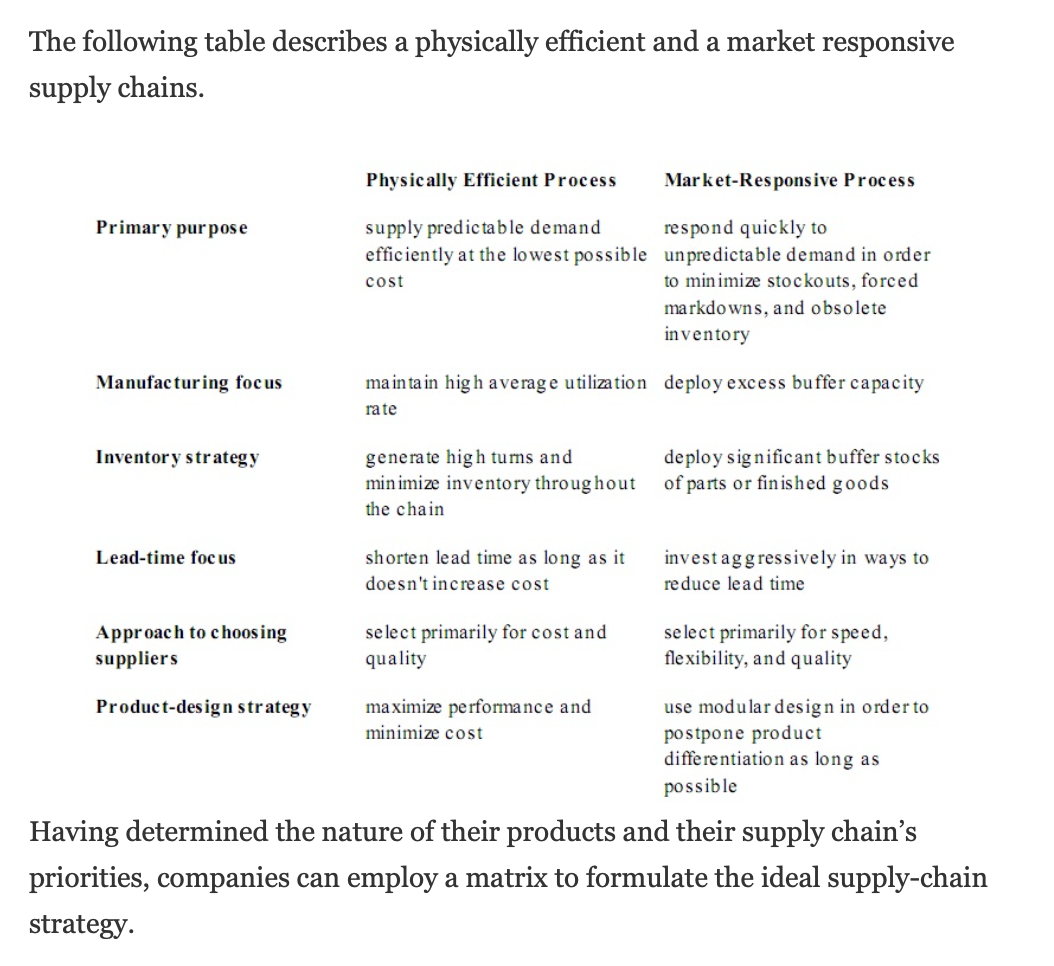

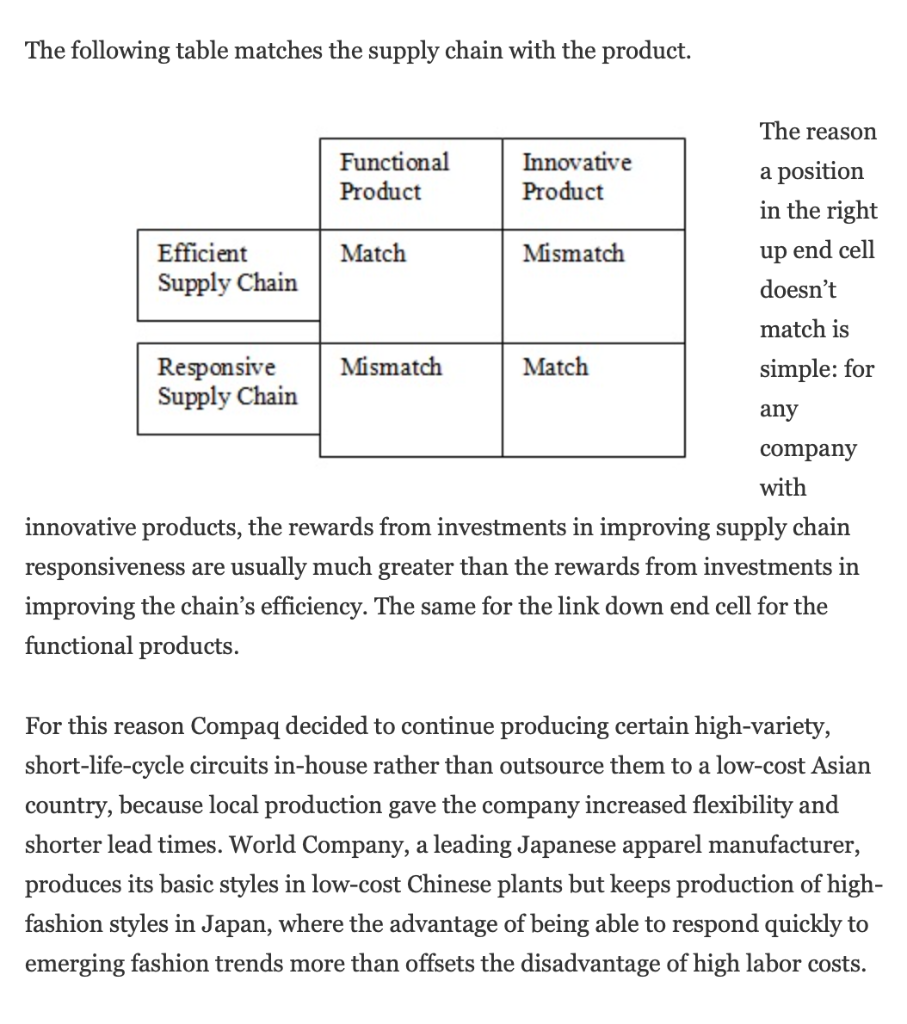

The right supply chain for a product Posted on September 9, 2010 1 Comment Supply chains in many industries suffer from an excess of some products and a shortage of others owing to an inability to predict demand. A good structure in the supply chain can avoid such problems and reduce the costs. It was developed a framework to devise the supply chain of a company based on the nature of their products. This framework helps to understand the nature of the demand for the products and devise the supply chain that can best satisfy that demand. The first step in devising an effective supply-chain strategy is therefore to consider the nature of the demand for the products one's company supplies. Many aspects are important (product life cycle, demand predictability, product variety, market standards for lead time and services), but if we watch the products on the basis of their demand patterns we divide them in two categories: primarily functional or primarily innovative. Functional products include many things people buy in the grocery store, retail outlet and may other shops. Because such products satisfy basic needs, which don't change much over time, they have stable, predictable demand and long life cycles. But their stability invites competition, which often leads to low profit margins. To avoid low margins, many companies introduce innovations in fashion or technology to give customers an additional reason to buy their offerings. Innovative products can help a company to achieve higher profit margins, but makes demand for them unpredictable. In addition, their life cycle is short usually just a few months and with a great variety of these products. These characteristics further increase unpredictability. With their high profit margins and volatile demand, innovative products require a fundamentally different supply chain than stable, low-margin functional products. The supply chain performs two distinct types of functions: a physical function and a market mediation function. A supply chain's physical function is readily apparent and includes converting raw materials into parts, components, and eventually finished goods, and transporting all of them from one point in the supply chain to the next. Less visible but equally important is market mediation, whose purpose is ensuring that the variety of products reaching the marketplace matches what consumers want to buy. Physical costs are the costs of production, transportation, and inventory storage. Market mediation costs arise when supply exceeds demand and a product has to be marked down and sold at a loss or when supply falls short of demand, resulting in lost sales opportunities and dissatisfied customers. The predictable demand of functional products makes market mediation easy because a nearly perfect match between supply and demand can be achieved. Companies that make such products are thus free to focus almost exclusively on minimizing physical costs. For this reason, companies usually create a schedule for assembling finished goods for at least the next month. In this instance, the important flow of information is the one that occurs within the chain as suppliers, manufacturers, and retailers coordinate their activities in order to meet predictable demand at the lowest cost. In this case the primary focus are the physical costs and to gain the physical efficiency through also some program as the continuous replenishment. With innovative products the approach has to be different. The uncertain market reaction to innovation increases the risk of shortages or excess supplies. The costs of these shortages are high and caused by the high profit margins and the importance of early sales in establishing market share. The cost of obsolescence and excess supplies are on the other side the same high. Hence market mediation costs predominate for these products, and they, not physical costs, should be managers' primary focus. Most important in this environment is to read early sales numbers or other market signals and to react quickly, during the new product's short life cycle. The critical decisions are about where in the chain to position inventory and available production capacity in order to hedge against uncertain demand. Suppliers should be chosen for their speed and flexibility, not for their low cost. A company should be directed to reduce the sales opportunities due to stockouts through increased speed, flexibility and responsiveness to the market. Although the distinctions between functional and innovative products and between physical efficiency and responsiveness to the market seem obvious, it is not easy to classify a product that are physically the same but can be either functional or innovative. This depends on the company but also on how the customer perceives a product. Devising the supply chain. For companies to be sure that they are taking the right approach, they first must determine whether their products are functional or innovative. The following table is a guideline for classifying products between functional or innovative. Functional (Predictable Demand) Innovative (Unpredictable Demand) Aspects of Demand Product life cycle more than 2 years 3 months to 1 year Contribution margin* 5% to 20% 20% to 60% Product variety low (10 to 20 variants per category) high (often millions of variants per category) 10% 40% to 100% Average margin of error in the forecast at the time production is committed A ver age stockout rate 1% to 2% 10% to 40% 0% 10% to 25% A ver age forced end-of-season mark down as percentage of full price Lead time required for made 6 months to 1 year 1 day to 2 weeks to-or der products The next step is to decide whether their company's supply chain is physically efficient or responsive to the market. The following table describes a physically efficient and a market responsive supply chains. Physically Efficient Process Market-Responsive Process Primary purpose supply predictable demand respond quickly to efficiently at the lowest possible unpredictable demand in order cost to minimize stockouts, forced markdowns, and obsolete inventory Manufacturing focus ma in ta in high average utilization deploy excess buffer capacity rate Inventory strategy generate high turns and minimize inventory throughout the chain deploy significant buffer stocks of parts or finished goods Lead-time focus shorten lead time as long as it doesn't increase cost invest aggressively in ways to reduce lead time Approach to choosing suppliers select primarily for cost and quality select primarily for speed, flexibility, and quality Product-design strategy maximize performance and minimize cost use modular design in order to postpone product differentiation as long as possible Having determined the nature of their products and their supply chain's priorities, companies can employ a matrix to formulate the ideal supply-chain strategy. The following table matches the supply chain with the product. The reason Functional Product Innovative Product Match Mismatch Efficient Supply Chain a position in the right up end cell doesn't match is simple: for Mismatch Match Responsive Supply Chain any company with innovative products, the rewards from investments in improving supply chain responsiveness are usually much greater than the rewards from investments in improving the chain's efficiency. The same for the link down end cell for the functional products. For this reason Compaq decided to continue producing certain high-variety, short-life-cycle circuits in-house rather than outsource them to a low-cost Asian country, because local production gave the company increased flexibility and shorter lead times. World Company, a leading Japanese apparel manufacturer, produces its basic styles in low-cost Chinese plants but keeps production of high- fashion styles in Japan, where the advantage of being able to respond quickly to emerging fashion trends more than offsets the disadvantage of high labor costs