Question: Batch processes are often used in chemical and pharmaceutical operations to achieve a desired chemical composition for the final product and typically involve a transient

Batch processes are often used in chemical and pharmaceutical operations to achieve a desired chemical composition for the final product and typically involve a transient heating operation to take the product to the desired process temperature. A typical scenario is shown below

Figure : The agitated vessel

The chemical to be heated is in the cylindrical tank and is heated by the coil of copper pipe which typically has heated water running through it The whole mixture is agitated by spinning blades in the center of the tank

For this project, we can simplify this scenario into a completely cylindrical tank as shown below

The dimensions of the tank and the agitator are given by

inner diameter of the tank

the agitator diameter

height of the tank

thickness of jacket no jacket

Figure : The dimensions of cylindrical vessel and bladed disc agitator

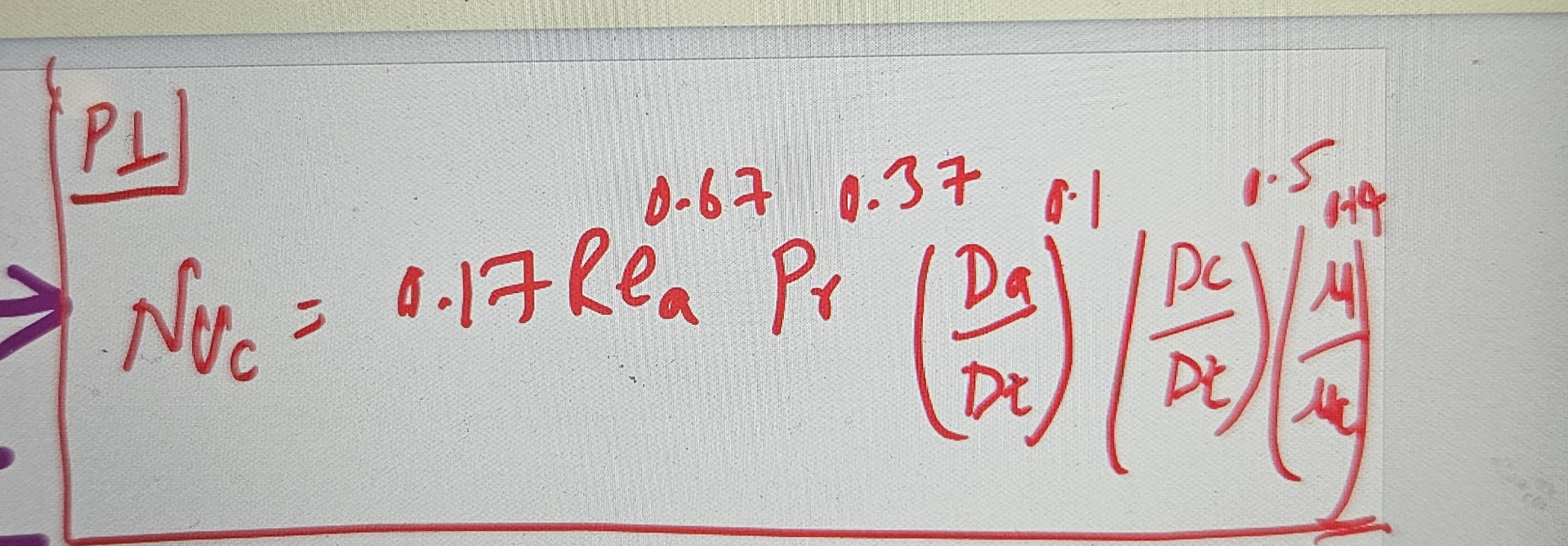

The agitator has flat unpitched blades attached to a disc and is rotating at There are baffles shown in Fig. to prevent formation of a vortex at the center of vessel, which impedes heat transfer. The dimensions given above mean that the proportions are which are "standard" proportions and are basis of many published correlations of agitator performance.

The tank contains a chemical mixture with properties close to water use water properties Assume the volume of the chemical is the volume inside the cylinder; you can neglect the volume occupied by the agitator. You can also assume the chemical inside the vessel is wellstirred such that it is at a uniform temperature at any given time. The chemical is to be heated from to a process temperature of by passing hot water through a coiled tube in the vessel not shown in the figure The inner diameter of the coiled tube is and its outer diameter is The pipe is made of copper and is long. The hot water enters the pipe at The flow rate of water inside the coiled tubing is

Assume that the vessel is wellinsulated no heat loss through walls of the vessel Estimate the initial heat rate from the hot water to the chemical. Also, find the pressure drop through the coil and the pumping power needed. also, find the time it takes for the chemical to reach Tf using the lumpedd capacitance method and assuming that the coefficients and properties above remain the same. solve using matlab code

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock