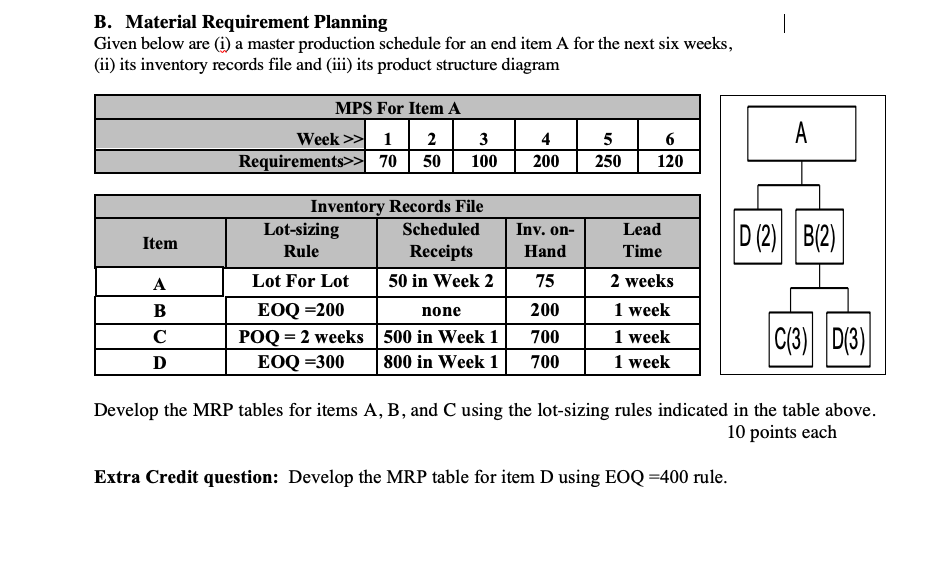

Question: B.Material Requirement Planning30 Points Given below are (i) a master production schedule for an end item A for the next six weeks, (ii) its inventory

B.Material Requirement Planning30 Points

Given below are (i) a master production schedule for an end item A for the next six weeks,

(ii) its inventory records file and (iii) its product structure diagram

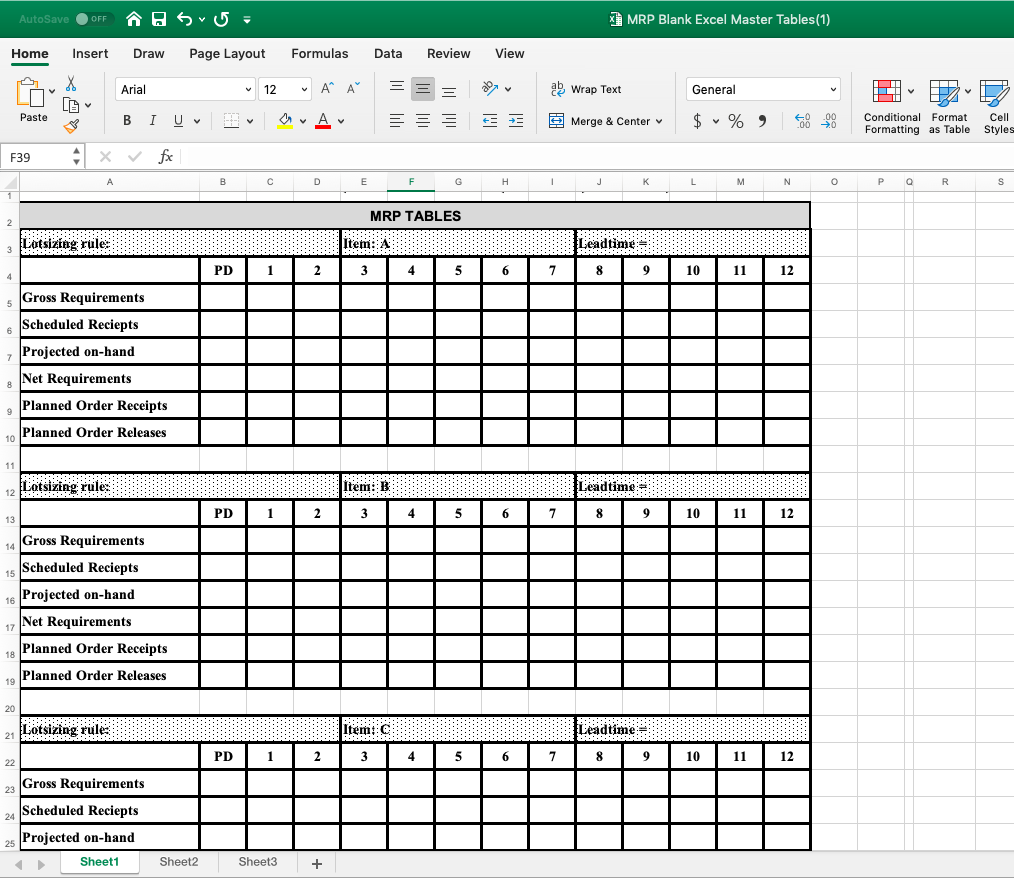

B. Material Requirement Planning Given below are (i) a master production schedule for an end item A for the next six weeks, (ii) its inventory records file and (iii) its product structure diagram MPS For Item A Week > > 2 3 4 5 6 A Requirements> > 70 50 100 200 250 120 Inventory Records File Item Lot-sizing Scheduled Inv. on- Lead Rule Receipts Hand Time D (2) B(2) A Lot For Lot 50 in Week 2 75 2 weeks B EOQ =200 none 200 1 week C POQ = 2 weeks 500 in Week 1 700 1 week D EOQ =300 700 1 week C (3) D(3) 800 in Week 1 Develop the MRP tables for items A, B, and C using the lot-sizing rules indicated in the table above. 10 points each Extra Credit question: Develop the MRP table for item D using EOQ =400 rule.AutoSave OFF Home MRP Blank Excel Master Tables(1) Insert Draw Page Layout Formulas Data Review View Arial 12 = 27 v 28 Wrap Text Paste General BIU V SVAY Merge & Center v X V fx $ ~ % " Conditional Format F39 Formatting as Table Styles Cell B C D E F G H J K L M N 0 P Q R MRP TABLES cutsizing ru PD Leadtime : 18: 2 3 5 6 Gross Requirements 8 10 11 12 Scheduled Reciepts Projected on-hand Net Requirements Order Receipts 10 Planned Order Releases BBBBBBBBB 12 cotsizing ru Item: B 86888868684 13 PD 1 2 Leadtime = 38: 3 4 5 6 7 8 9 Gross Requirements 10 11 12 15 Scheduled Reciepts 16 Projected on-hand Net Requirements 18 Planned Order Receipts 19 Planned Order Releases 20 21 Itemi CH PD 2 3 4 Gross Requirements 10 11 12 24 | Scheduled Reciepts Projected on-hand Sheet1 Sheet2 Sheet3 +

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts