Question: Bogged Machine Shop, Inc., has a 1-year contract for the production of 75,000 gear housings for a new off-road vehicle. Owner Luis Borges hopes the

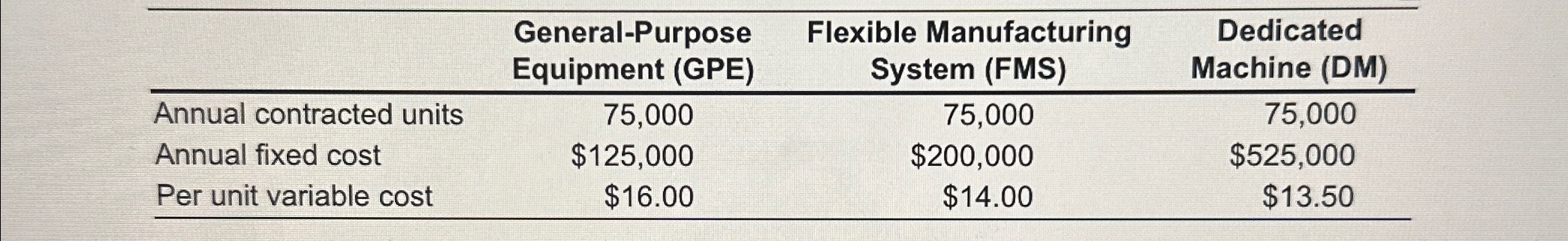

Bogged Machine Shop, Inc., has a 1-year contract for the production of 75,000 gear housings for a new off-road vehicle. Owner Luis Borges hopes the contract will be extended and the volume increased next year. Borges has developed costs for three alternatives. They are general-purpose equipment (GPE), flexible manufacturing system (FMS), and expensive, but efficient, dedicated machine (DM). The cost data follow:

Based on the total cost, the process that is best suited for the current contracted volume is: DM, FMS, GPE

v1 =(enter your response as a whole number).

V2=(enter your response as a whole number).

V3=(enter your response as a whole number).

\begin{tabular}{lccr} \hline & \begin{tabular}{c} General-Purpose \\ Equipment (GPE) \end{tabular} & \begin{tabular}{c} Flexible Manufacturing \\ System (FMS) \end{tabular} & \begin{tabular}{c} Dedicated \\ Machine (DM) \end{tabular} \\ \hline Annual contracted units & 75,000 & 75,000 & 75,000 \\ Annual fixed cost & $125,000 & $200,000 & $525,000 \\ Per unit variable cost & $16.00 & $14.00 & $13.50 \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts