Question: Bondi Cerealsoperators ( laying off ) , under - utilise its current work force or build up inventories. All these options have a cost associated

Bondi Cerealsoperators laying off underutilise its current work force or build up inventories. All these options

have a cost associated with them and businesses often use a combination of these strategies and

policies, not just a single option. Determining the least expensive option is difficult and a challenge

for many businesses and an important issue for Bondi Cereals.

Useful Formulae

All demand in each week must be met, either by producing product, or by supplying orders out of

inventory or by creating backorders. For instance, at the beginning of each period week the

factory knows what inventory it has in stock at the end of the previous period The net demand

for that period will then be the gross demand refer Tables and minus what it has in inventory

if : plus any backorders carried forward if : The factory will then decide how

much to produce we will call this This will depend on the demand as well as whether we want

to produce more than demand and build inventory or produce less than demand and create

backorders.

We can derive a formula for :

Where:

equals gross demand in period

equals a positive inventory holding carried forward from the previous period.

equals backorders carried fTable shows the selling price, retail markup, discount and manufacturing cost structure

e

The purpose of this question is to apply one of the most important and widely used

mathematical algorithms, Linear Programming, to solve one of the most common issues faced

by corporations, the allocation of resources to achieve an optimum outcome. In this

assignment you are given a realistic business scenario complete with operational data and

costing information. You will work through the assignment in a systematic way by

establishing the decision variables, the objective function, identifying the constraints, building

the model, verifying and validating, running the model, interpreting the results, testing different

scenarios, and making recommendatione

Close

Bondi Cereals is a newly formed company that wants to become a premium supplier of high

quality cereals and is based right here in Sydney's eastern beaches. The company offers three

varieties: Vanilla, Hazelnut, and Chocolate.

Bondi produces its product from locally produced grains and ingredients as well as some

imported product, such as vanilla and chocolate. The operation involves mixing, blending, and

baking in strict conformance with their unique recipes.

In March a meeting is scheduled between Tillie and Merle, the two owners. Fixed

volume purchase contracts have been signed with suppliers and it is time to plan the

production of the cereal. The purpose of the meeting is to discuss the production strategy and

the allocation and scheduling of resources to meet the production forecast.

Sales Forecast

Since Bondi is a newcomer to the market, its brand is not yet well known and therefore this

product will initially be sold through a limited number of local supermarkets as a trial. Bondi is

hopeful that its cereal will catch on and that its product line will continue to grow. However, since

their brand is new and unproven and competition is strong, especially from established suppliers,

Merle has come up with a conservative and perhaps even a pessimistic sales forecast, on a

weekly basis for the first six weeks of the trial period. This is shown in Table The Factory

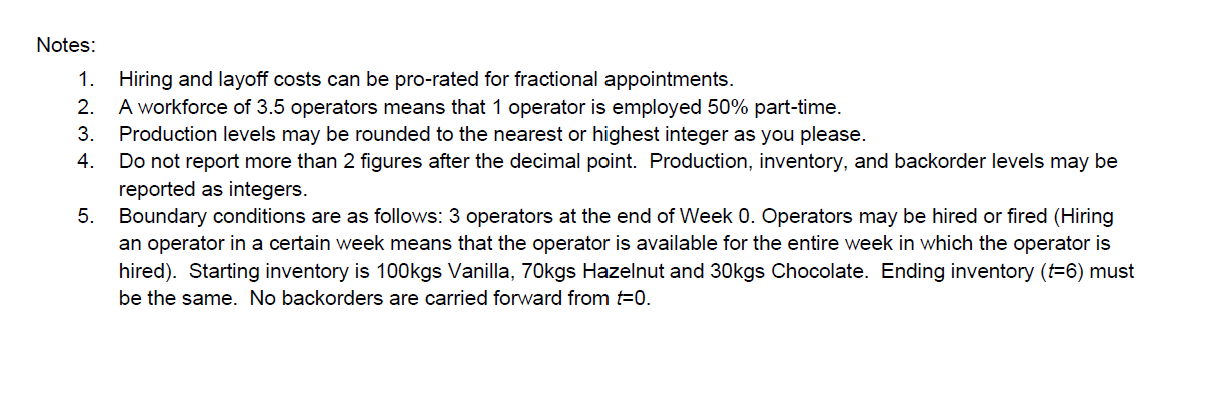

The factory currently employs casual operators. An operator can produce of product per

hour shift. The factory only works a single shift of hours per day minus hour for breaks days

per week. Merle and Tillie are not considering adding a second shift to any of the days but are

willing to commit to overtime. The overtime rate of pay is higher than standard pay.

The production strategy is to manage the variation in sales forecasts and production schedules in

three ways:

By varying the level of operators hiring and firing

Working overtime nb currently capped to hours per week in total. Not per person per

week

Underutilising capacity by maintaining the current workforce level but reducing the

production rate

Building inventory.

Creating backorders nb currently capped to boxes in total each week, regardless of

flavour

When sales are increasing, the business may increase casual operators hiring use overtime, or

draw down existing inventory. Similarly, when sales are decreasing, the firm might decrease casual

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock