Question: Bright factory will launch a new cherry variant soap within the next 6 month. The raw materials are imported from abroad with imported lead time

"Bright" factory will launch a new cherry variant soap within the next 6 month. The raw materials are imported from abroad with imported lead time of 2 months (sea fright). Current line utilization that runs 24 hours x 6 days is already running in a very tight capacity. Another complexity in this project is that the waste generated by change over (CO) activity to cherry variant is 500kg, two times higher than the existing variant. Currently, we are also facing the pandemics situation of COVID-19 in which affect distribution of our RMS (Raw Material Sourcing), and delivery of FG (Finished Good) to our customers.

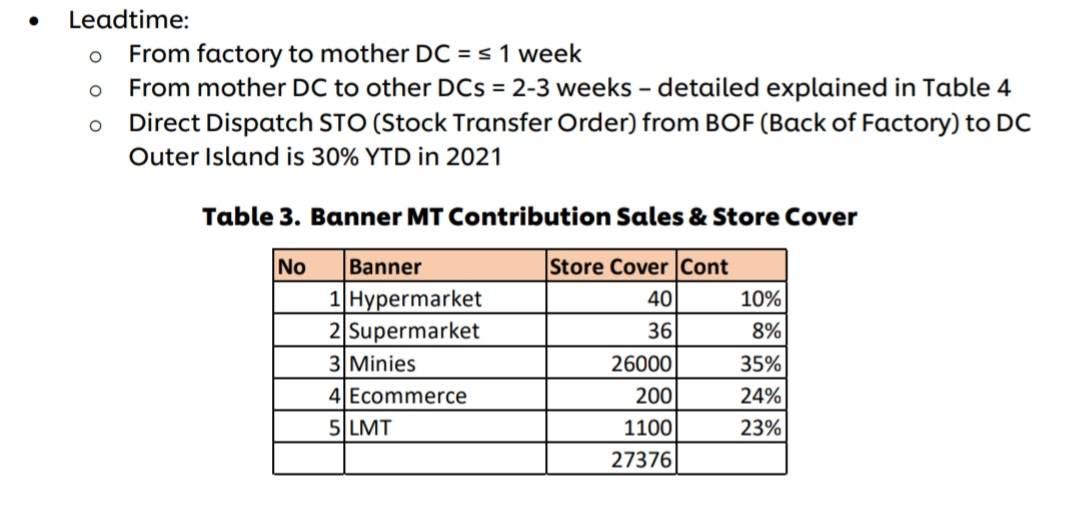

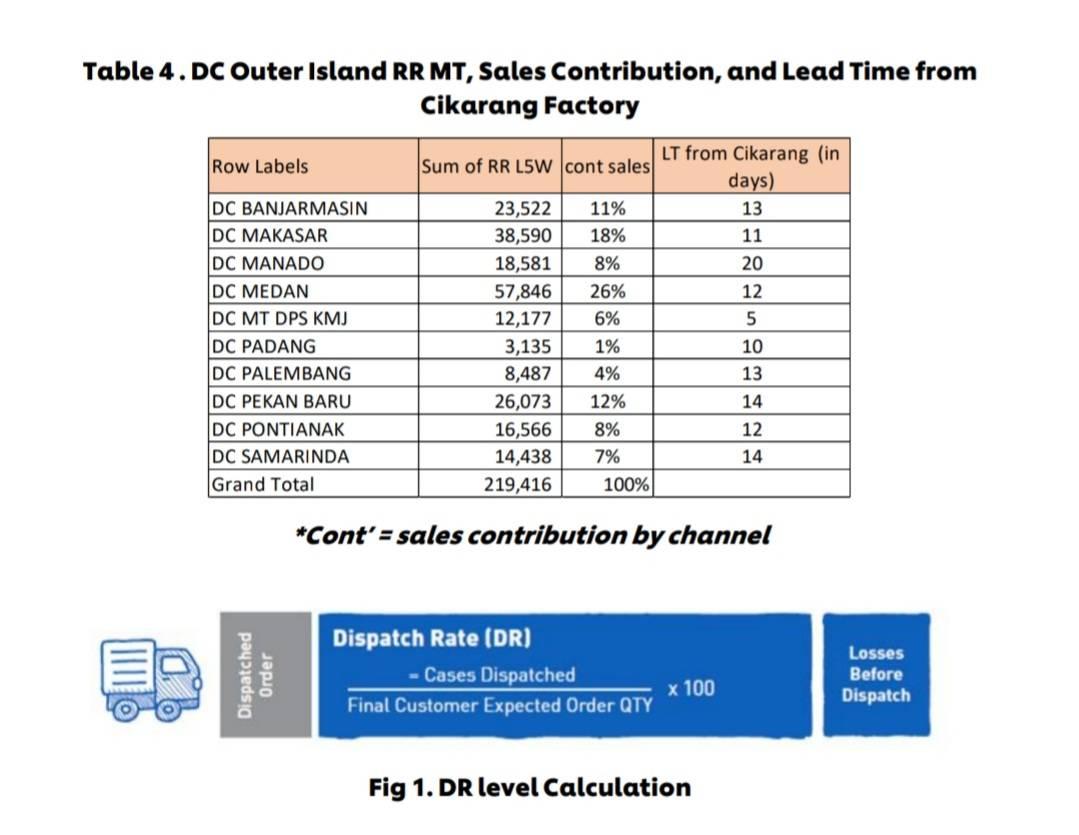

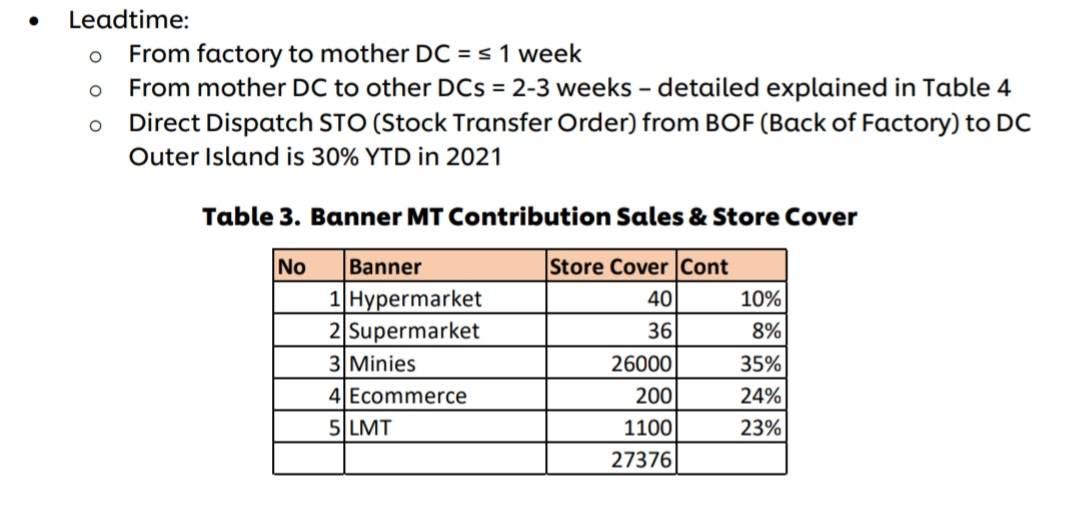

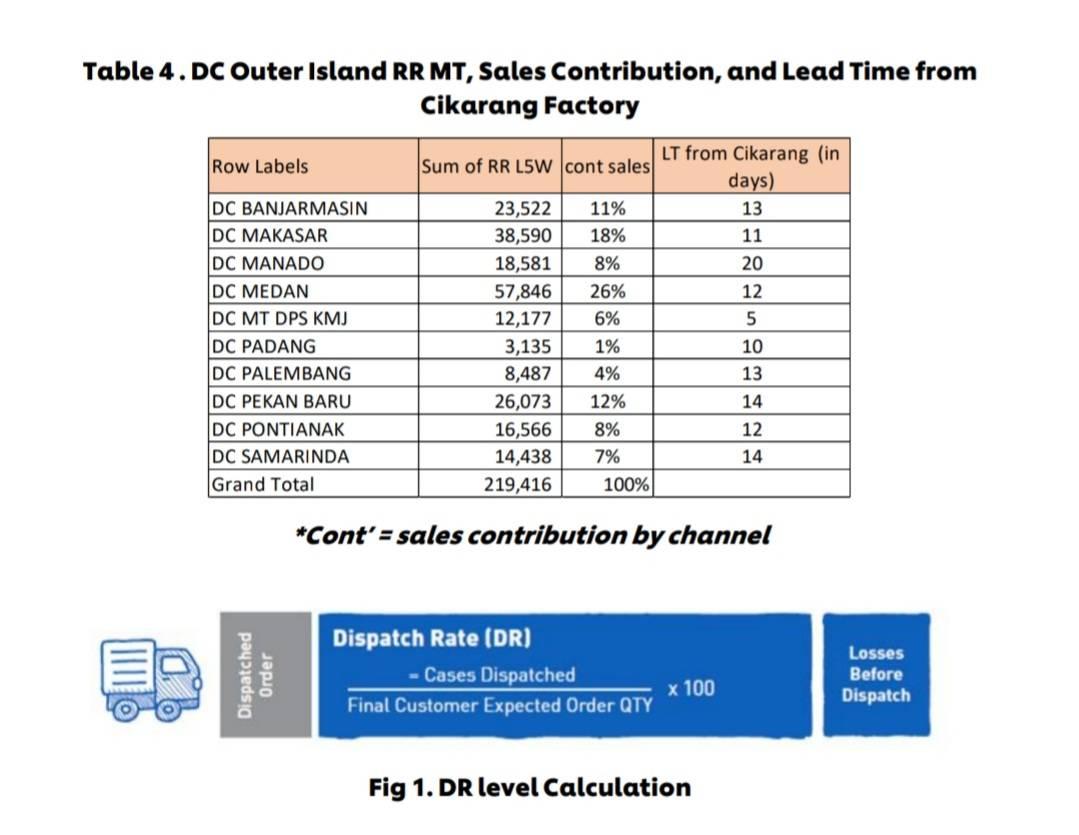

The cherry variant soap is expected to be on shelf by april 2022, means we only have 6 month to design the supply chain model, build the supply chain capability, and deliver product to the market. For the first 6 months, Cherry variant to be distributed to 500 offline stores (Supermarket, E-Commerce, and Local Modern Trade (LMT)) across DC (Distribution Centre) including Outside island DCs which becomes the main focus of service improvement (DR level). Target for DR (Dispatch Rate) level is minimum 93% DR across all DC Outer Island. Dispatch Rate Calculation is explained in Figure 1. After produced in Cikarang site (the Bright Factory) the products will be delivered to Mother DC (DC in Java island) before it gets transported to 11 other DCs located outside the island.

Please create your end-to-end supply chain plan (explain using timeline from October 2021-April 2022) and explain your priority to which DCs are your finished good to be delivered first to achieve Dispatch Rate (DR) minimum 93%!

Please create your end-to-end supply chain plan (explain using timeline from October 2021-April 2022) and explain your priority to which DCs are your finished good to be delivered first to achieve Dispatch Rate (DR) minimum 93%!

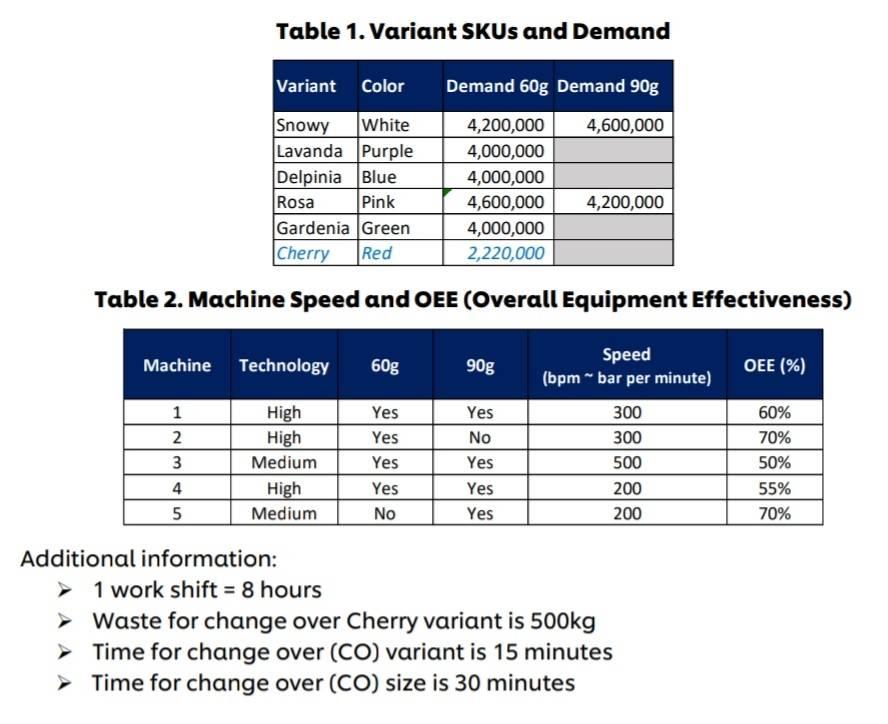

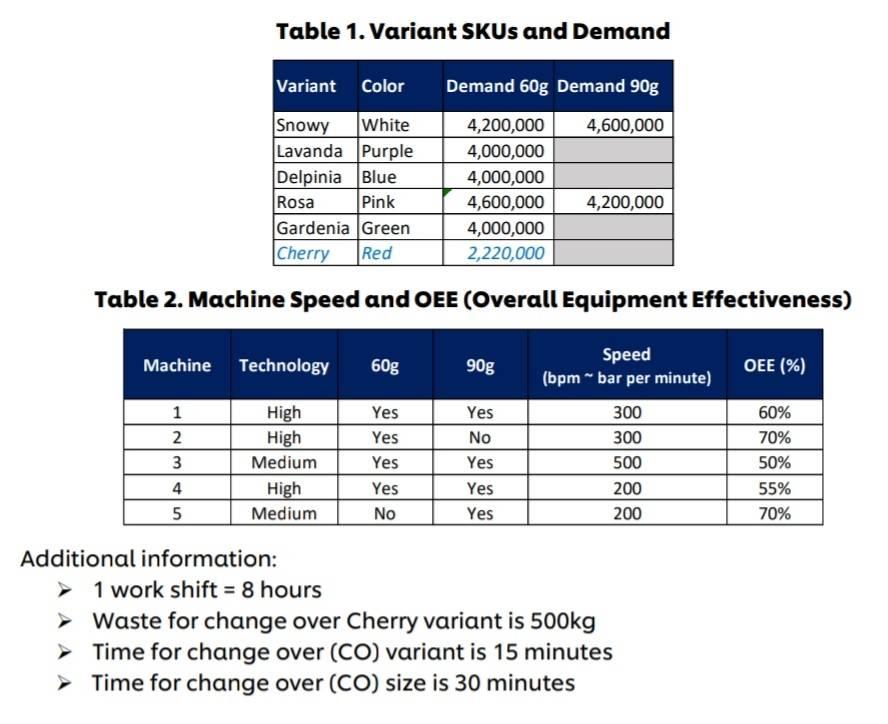

Table 1. Variant SKUs and Demand Variant Color Demand 60g Demand 90g 4,600,000 Snowy White Lavanda Purple Delpinia Blue Rosa Pink Gardenia Green Cherry Red 4,200,000 4,000,000 4,000,000 4,600,000 4,000,000 2,220,000 4,200,000 Table 2. Machine Speed and OEE (Overall Equipment Effectiveness) Machine Technology 60g 90g Speed (bpm bar per minute) OEE (%) NIE 1 2 3 4 5 High High Medium High Medium Yes Yes Yes Yes No Yes No Yes Yes Yes 300 300 500 200 200 60% 70% 50% 55% 70% Additional information: 1 work shift = 8 hours Waste for change over Cherry variant is 500kg Time for change over (CO) variant is 15 minutes Time for change over (CO) size is 30 minutes o Leadtime: From factory to mother DC = s 1 week From mother DC to other DCS = 2-3 weeks - detailed explained in Table 4 Direct Dispatch STO (Stock Transfer Order) from BOF (Back of Factory) to DC Outer Island is 30% YTD in 2021 O o Table 3. Banner MT Contribution Sales & Store Cover No Banner 1 Hypermarket 2 Supermarket 3 Minies Store Cover Cont 40 36 10% 8% 35% 4 Ecommerce 26000 200 1100 27376 24% 23% 5LMT Table 4.DC Outer Island RR MT, Sales Contribution, and Lead Time from Cikarang Factory Row Labels Sum of RR L5W cont sales LT from Cikarang (in days) 13 11% 18% 11 20 12 5 DC BANJARMASIN DC MAKASAR DC MANADO DC MEDAN DC MT DPS KMJ DC PADANG DC PALEMBANG DC PEKAN BARU DC PONTIANAK DC SAMARINDA Grand Total 23,522 38,590 18,581 57,846 12,177 3,135 8,487 26,073 16,566 14,438 219,416 10 + 8% 26% 6% 1% 4% 12% 8% 7% 100% 13 14 12 14 *Cont' = sales contribution by channel Dispatched Order Dispatch Rate (DR) - Cases Dispatched Final Customer Expected Order QTY Losses Before Dispatch x 100 Fig 1. DR level Calculation Table 1. Variant SKUs and Demand Variant Color Demand 60g Demand 90g 4,600,000 Snowy White Lavanda Purple Delpinia Blue Rosa Pink Gardenia Green Cherry Red 4,200,000 4,000,000 4,000,000 4,600,000 4,000,000 2,220,000 4,200,000 Table 2. Machine Speed and OEE (Overall Equipment Effectiveness) Machine Technology 60g 90g Speed (bpm bar per minute) OEE (%) NIE 1 2 3 4 5 High High Medium High Medium Yes Yes Yes Yes No Yes No Yes Yes Yes 300 300 500 200 200 60% 70% 50% 55% 70% Additional information: 1 work shift = 8 hours Waste for change over Cherry variant is 500kg Time for change over (CO) variant is 15 minutes Time for change over (CO) size is 30 minutes o Leadtime: From factory to mother DC = s 1 week From mother DC to other DCS = 2-3 weeks - detailed explained in Table 4 Direct Dispatch STO (Stock Transfer Order) from BOF (Back of Factory) to DC Outer Island is 30% YTD in 2021 O o Table 3. Banner MT Contribution Sales & Store Cover No Banner 1 Hypermarket 2 Supermarket 3 Minies Store Cover Cont 40 36 10% 8% 35% 4 Ecommerce 26000 200 1100 27376 24% 23% 5LMT Table 4.DC Outer Island RR MT, Sales Contribution, and Lead Time from Cikarang Factory Row Labels Sum of RR L5W cont sales LT from Cikarang (in days) 13 11% 18% 11 20 12 5 DC BANJARMASIN DC MAKASAR DC MANADO DC MEDAN DC MT DPS KMJ DC PADANG DC PALEMBANG DC PEKAN BARU DC PONTIANAK DC SAMARINDA Grand Total 23,522 38,590 18,581 57,846 12,177 3,135 8,487 26,073 16,566 14,438 219,416 10 + 8% 26% 6% 1% 4% 12% 8% 7% 100% 13 14 12 14 *Cont' = sales contribution by channel Dispatched Order Dispatch Rate (DR) - Cases Dispatched Final Customer Expected Order QTY Losses Before Dispatch x 100 Fig 1. DR level Calculation

Please create your end-to-end supply chain plan (explain using timeline from October 2021-April 2022) and explain your priority to which DCs are your finished good to be delivered first to achieve Dispatch Rate (DR) minimum 93%!

Please create your end-to-end supply chain plan (explain using timeline from October 2021-April 2022) and explain your priority to which DCs are your finished good to be delivered first to achieve Dispatch Rate (DR) minimum 93%!