Question: c) Is this possible to increase the efficiency to 100%? d) What is the theoretical minimum number of workstations? The following table details the tasks

c) Is this possible to increase the efficiency to 100%?

d) What is the theoretical minimum number of workstations?

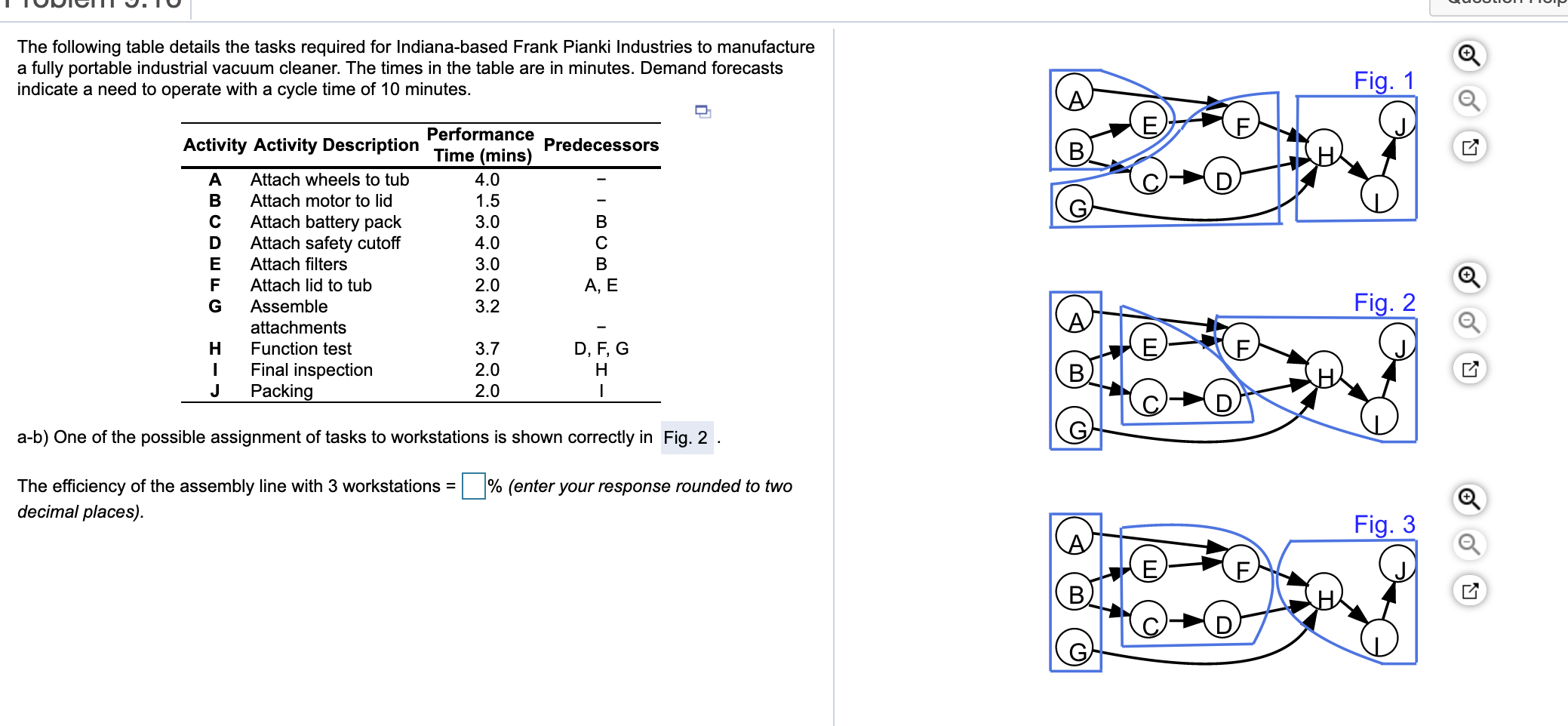

The following table details the tasks required for Indiana-based Frank Pianki Industries to manufacture a fully portable industrial vacuum cleaner. The times in the table are in minutes. Demand forecasts indicate a need to operate with a cycle time of 10 minutes. Fig. 1 B 2 Performance Activity Activity Description Predecessors Time (mins) A Attach wheels to tub 4.0 B Attach motor to lid 1.5 C Attach battery pack 3.0 B D Attach safety cutoff 4.0 E Attach filters 3.0 B F Attach lid to tub A, E G Assemble 3.2 attachments H Function test 3.7 D, F, Final inspection 2.0 . Packing 2.0 1 2.0 Fig. 2 a-b) One of the possible assignment of tasks to workstations is shown correctly in Fig. 2 The efficiency of the assembly line with 3 workstations =% (enter your response rounded to two decimal places). Fig. 3 i Please copy and paste data from text area below. Selected delimiter: Tab Activity Activity Description Performance Time (mins) Immediate Predecessors A Attach wheels to tub 4.0 B Attach motor to lid 1.5 Attach battery pack 3.0 B D Attach safety cutoff 4.0 E Attach filters 3.0 B F Attach lid to tub 2.0 A, E G Assemble attachments 3.2 H Function test 3.7 D, F, G I Final inspection 2.0 H J Packing 2.0 I DoneStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts