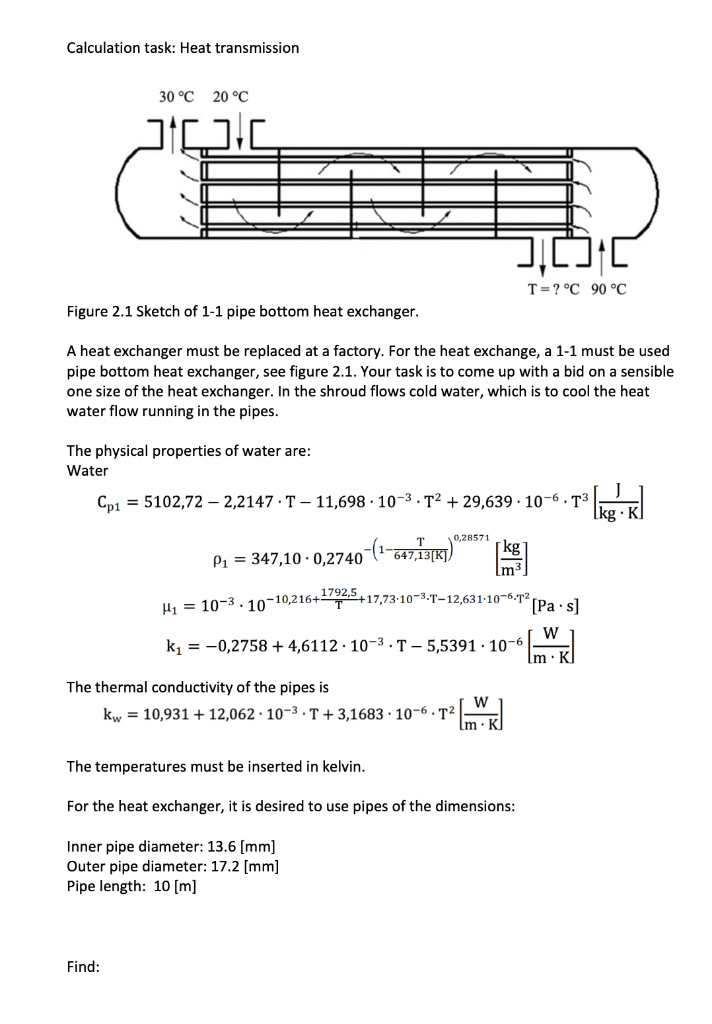

Question: Calculation task: Heat transmission 30 C 20 C DC 1.DC T= ? C 90 C Figure 2.1 Sketch of 1-1 pipe bottom heat exchanger. A

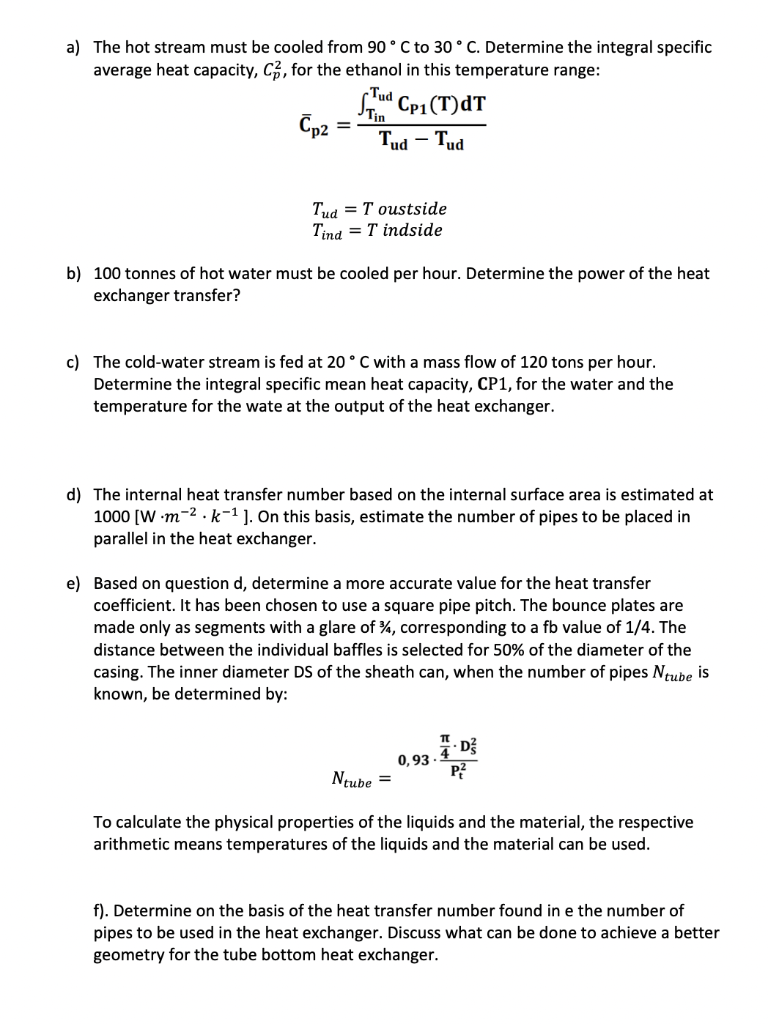

Calculation task: Heat transmission 30 C 20 C DC 1.DC T= ? C 90 C Figure 2.1 Sketch of 1-1 pipe bottom heat exchanger. A heat exchanger must be replaced at a factory. For the heat exchange, a 1-1 must be used pipe bottom heat exchanger, see figure 2.1. Your task is to come up with a bid on a sensible one size of the heat exchanger. In the shroud flows cold water, which is to cool the heat water flow running in the pipes. The physical properties of water are: Water * 1] 0,28571 m Cp1 = 5102,72 2,2147. T- 11,698 . 10-3.T2 + 29,639. 10-6.13 Ikg. Pa = 347,10 -0,2740-(1-647,7 47,13[k]) [kg Hi = 10-3 . 10-10,216+17,73-10-3-1-12,631-10-6.12, [Pas] W ki = -0,2758 + 4,6112. 10-3.1- 5,5391 10-6 Im.K 17922+ The thermal conductivity of the pipes is W kw = 10,931 + 12,062 . 10-3. T +3,1683 10-6.12 Im. The temperatures must be inserted in kelvin. For the heat exchanger, it is desired to use pipes of the dimensions: Inner pipe diameter: 13.6 [mm] Outer pipe diameter: 17.2 [mm] Pipe length: 10 [m] Find: a) The hot stream must be cooled from 90 C to 30 C. Determine the integral specific average heat capacity, C, for the ethanol in this temperature range: Sud Cpu (T)dt Tin Cp2 Tud - Tud Tud = T oustside Tind = T indside b) 100 tonnes of hot water must be cooled per hour. Determine the power of the heat exchanger transfer? c) The cold-water stream is fed at 20C with a mass flow of 120 tons per hour. Determine the integral specific mean heat capacity, CP1, for the water and the temperature for the wate at the output of the heat exchanger. d) The internal heat transfer number based on the internal surface area is estimated at 1000 [Wm-2.k-1). On this basis, estimate the number of pipes to be placed in parallel in the heat exchanger. e) Based on question d, determine a more accurate value for the heat transfer coefficient. It has been chosen to use a square pipe pitch. The bounce plates are made only as segments with a glare of %, corresponding to a fb value of 1/4. The distance between the individual baffles is selected for 50% of the diameter of the casing. The inner diameter DS of the sheath can, when the number of pipes Ntube is known, be determined by: TE 0,93 Ntube = P? To calculate the physical properties of the liquids and the material, the respective arithmetic means temperatures of the liquids and the material can be used. f). Determine on the basis of the heat transfer number found in e the number of pipes to be used in the heat exchanger. Discuss what can be done to achieve a better geometry for the tube bottom heat exchanger. Calculation task: Heat transmission 30 C 20 C DC 1.DC T= ? C 90 C Figure 2.1 Sketch of 1-1 pipe bottom heat exchanger. A heat exchanger must be replaced at a factory. For the heat exchange, a 1-1 must be used pipe bottom heat exchanger, see figure 2.1. Your task is to come up with a bid on a sensible one size of the heat exchanger. In the shroud flows cold water, which is to cool the heat water flow running in the pipes. The physical properties of water are: Water * 1] 0,28571 m Cp1 = 5102,72 2,2147. T- 11,698 . 10-3.T2 + 29,639. 10-6.13 Ikg. Pa = 347,10 -0,2740-(1-647,7 47,13[k]) [kg Hi = 10-3 . 10-10,216+17,73-10-3-1-12,631-10-6.12, [Pas] W ki = -0,2758 + 4,6112. 10-3.1- 5,5391 10-6 Im.K 17922+ The thermal conductivity of the pipes is W kw = 10,931 + 12,062 . 10-3. T +3,1683 10-6.12 Im. The temperatures must be inserted in kelvin. For the heat exchanger, it is desired to use pipes of the dimensions: Inner pipe diameter: 13.6 [mm] Outer pipe diameter: 17.2 [mm] Pipe length: 10 [m] Find: a) The hot stream must be cooled from 90 C to 30 C. Determine the integral specific average heat capacity, C, for the ethanol in this temperature range: Sud Cpu (T)dt Tin Cp2 Tud - Tud Tud = T oustside Tind = T indside b) 100 tonnes of hot water must be cooled per hour. Determine the power of the heat exchanger transfer? c) The cold-water stream is fed at 20C with a mass flow of 120 tons per hour. Determine the integral specific mean heat capacity, CP1, for the water and the temperature for the wate at the output of the heat exchanger. d) The internal heat transfer number based on the internal surface area is estimated at 1000 [Wm-2.k-1). On this basis, estimate the number of pipes to be placed in parallel in the heat exchanger. e) Based on question d, determine a more accurate value for the heat transfer coefficient. It has been chosen to use a square pipe pitch. The bounce plates are made only as segments with a glare of %, corresponding to a fb value of 1/4. The distance between the individual baffles is selected for 50% of the diameter of the casing. The inner diameter DS of the sheath can, when the number of pipes Ntube is known, be determined by: TE 0,93 Ntube = P? To calculate the physical properties of the liquids and the material, the respective arithmetic means temperatures of the liquids and the material can be used. f). Determine on the basis of the heat transfer number found in e the number of pipes to be used in the heat exchanger. Discuss what can be done to achieve a better geometry for the tube bottom heat exchanger

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts