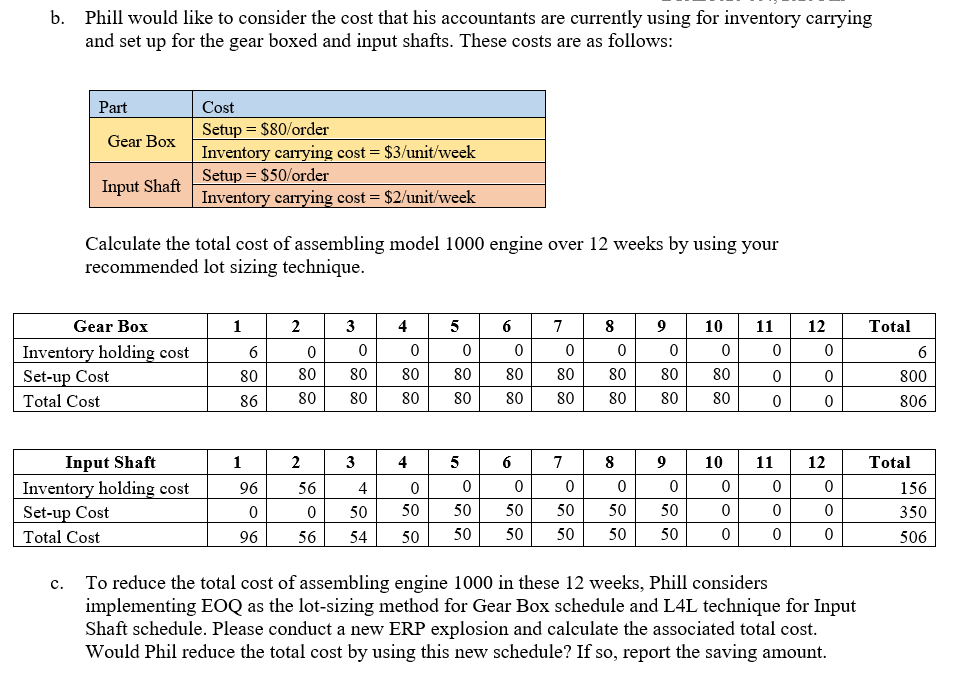

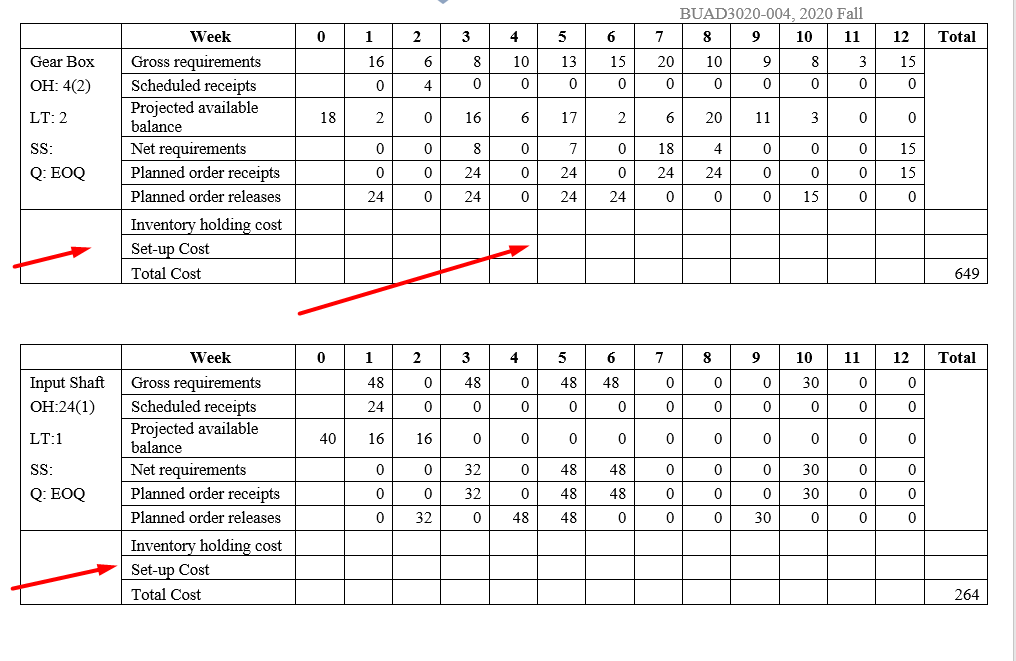

Question: Can some please help me to complete part C which has empty tables. Also please guide me if other parts have some mistake. Thanks In

Can some please help me to complete part C which has empty tables. Also please guide me if other parts have some mistake. Thanks

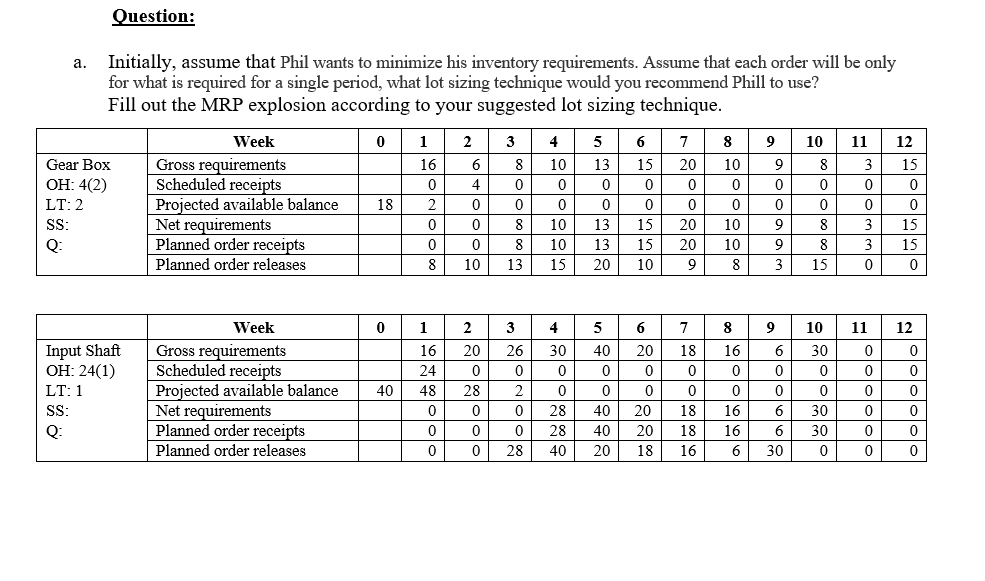

In preparing the MRP example, Phil planned to use the worksheets shown the below and to make the following assumptions:

- Eighteen gear boxes are on hand at the beginning of Week 1, and four gear boxes are currently on order to be delivered at the start of Week 2.

- Forty input shafts are on hand at the start of Week 1, and 24 are scheduled for delivery at the beginning of Week 1.

| Model 1000 Master Schedule | ||||||||||||

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Demand | 16 | 6 | 8 | 10 | 13 | 15 | 20 | 10 | 9 | 8 | 3 | 15 |

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts