Question: can someone help me answer the last three questions please. Whenever Jason Roberts thought about yoing to work on Friday morning, he starled to get

can someone help me answer the last three questions please.

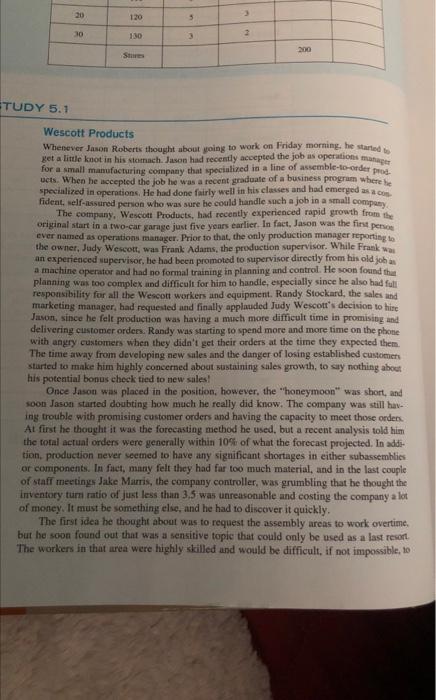

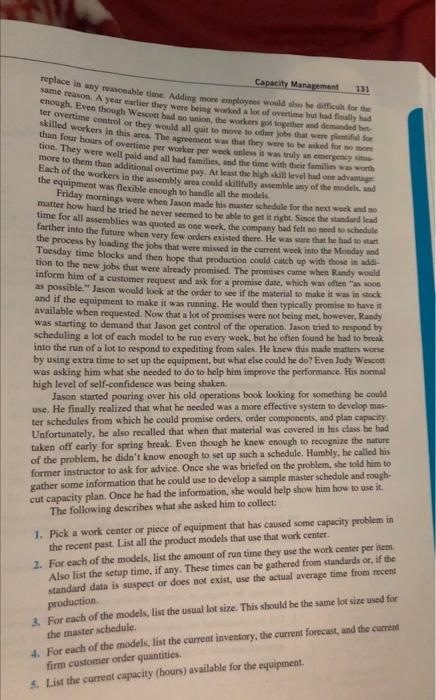

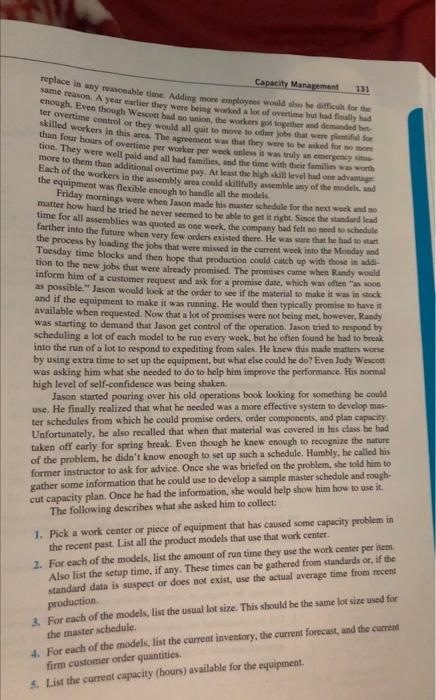

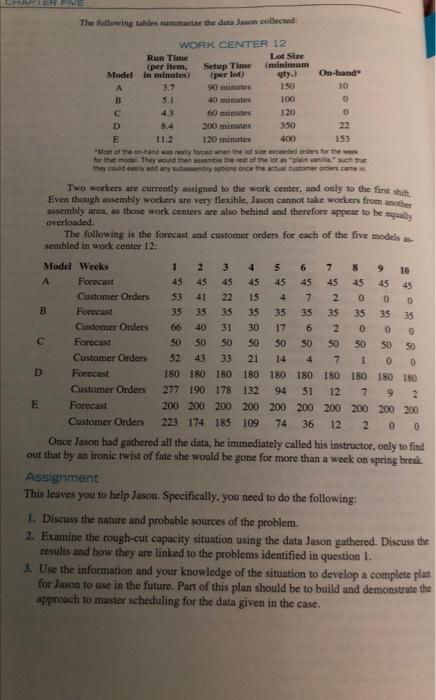

Whenever Jason Roberts thought about yoing to work on Friday morning, he starled to get a litule knot in his stemach. Jason had recently accepted the job as operations mataget for a small manufacturing company that specialized in a line of assemble-to-order pros. vets. When he accepted the job he was a recent graduate of a business program where he specialized in operations. He had done fairly well in his classes and had emerged as a confident, self-assured penion who was sure be could handle such a job in a small compery. The company, Wescon Products, had recently experienced rapid growth from the original start in a two-car garage just five years earlier. In fact, Jason was the firs perioe ever named as operations manager. Prior to that, the only production manager reportieg to the owner, Jady Wescot, was Frank Adams, the production supervisor. While Frakk wan an experienced wupervisor, he had been promoted to supervisor directly from his old joh as a machine operator and had no formal training in planning und control. He soon found that planning was too complex and difficult for him to handle, eypecially since be also had full responsibility for all the Wescot workers and equipment. Randy. Stockard, the sales and marketing manager, bad requested and finally applauded Judy Wescott's decivion to hise Javon, since he felt production was having a much more difficult time in promising and delivering customer orders. Randy was starting to spend more and more time on the phote with angry customers when they dida't get their orders at the time they expected them. The time away from developing new sales and the danger of losing established customen started to make him highly concerned about sustaining sales growh, to say nothing aboet his potential bonus check tied to new sules! Once Jason was placed in the position, however, the "honeymoon" was short, and soon Jason started doubting bow much he really did know. The company was still having trouble with promising customer orders and having the capacity to meet those orden At first he thought it was the forecasting method be used, but a recent analysis told him the total actual orders were generally within 10 si of what the forecast projected. In addtion, production never seemed to have any significant shortages in either subassembties or components. In fact, many felt they had far too much material, and in the last couple of staff meetings Jake Marris, the company controller, was grumbling that he thought the inventory turri ratio of just less than 3,5 was unreasonuble and costing the company a lot of money. It must be something else, and he had to discover it quickly. The first idea he thought about was to request the assembly areas to work overtime. bat he soon found oot that was a sensitive topic that could only be used as a last rewort. The workers in that weat were highly skilled and would be difficult, if not impossible, 10 Capacity Managemont 131 replace in any reaspeablie time. Adding more expployees would also the difficust for toc Same teasoni A year rarlier they were being worked a lot of owrrtime but had findlly bad enough. Even though Wesenet bad no uninn, the worken got together and demasted ber. ter overtime control or they would all quit to move to other jobe that were plentiful for skilted workers in this area. The agreemicot was that they were to te aiked fut oo mors than four hours of overtime per worker per week tenlew it was truly as emergeacy sitastion. They were well paid and all had families, and the time with their families was worth more to them than additional overtime pay. At leat the high skill level hial ene advantage Each of the workens in the assembly area could skillfally assemble any of the models, and the equipment was flexible enoegh to handle all the models. Friday mornings were when Jason made his master schedule for the next week und no matter how hard he tried be never seemed to be able to get it right. Since the standard lead time for all assemblies was quoted as one week, the company had felt no need to schadule farther into the fature when very few orders existed there. He was sure that he had to sturt the process by losding the jobs that were missed in the current week into the Monday and Tuesday time blocics and then hope that peoduction coold catich up with those in addition to the new jobs that were already promised. The promises came when Bandy wexild inform him of a customer request and axk for a promise dase, which was often "as aook as possible," Jason would look at the order to see if ithe material to make it wai in stock and if the equipment to make it was running. He would then typically promise to have if available when requested. Now that a lot of promises were not being met, however, Randy. Was starting to demand that Jason get control of the operation. Jason tried to respond by scheduling a lot of each model to be ran every week, bot he often found he had to break. into the run of a lot fo respond to expediting from sales. He knew this made matiers woene by using extra time to set up the equipment, bet what else could he do? Even Judy Wescopt Was asking him what she needed to do to belp him high level of self-confidence was being shaken. Jason started pouring over his old operations book looking for sornething be could use. He finally realized that what he needed was a more effective system to develop matter schedules from which he could promise orders, otder components, and plan capaciry. Unfortunately, he also recalled that when that material was covered in his class be had taken off early for spring break. Even though be knew enough to recognize the natare of the problem, he didn't know enongh to set up such a schedule. Humbly. he called his former instructor to ask for advice. Once she was brieied on the problem, she told him to gather some information that he could use to develop a sample master schedule and rodghcut capacity plan. Once he had the information, she would help show him how to use it. The following describes what she asked him to collect: 1. Pick a work ceater or picce of equipment that has caused some capacity problem in the recent past. List all the product models that use that work center. 2. For each of the models, list the amount of run time they use the work center per item. Also list the setup time. if any. These times can be gathered from standards or, if the standard data is suspect of does not exist, use the actual average time from recent production. 3. For cach of the models, list the usual lot size. This should be the same lot size used for the master schedule. 4. For each of the models, list the current iaveatory, the cument forecast, and the current firm customer order quantities. 5. List the current capacity (hours) available for the equipment. Two workers are currently assigned to the work center, and only to the first shith. Fven though assembly workers are very flexible, Jason cannot take workers from another assembly area, as those work ceeters are also behind and therefore appear to be equaliy overtanded. The following is the forecast and custotner orden for each of the five models assensbled in work center 12: Once Jason had githered itl the data, he immediately called his instructor, anly to find out that by in ironie twist of fate she would be gone for more than a week on spring break. assigmintiti This leaves you to help Jason. Specifically. you need to do the following: 1. Diseus the nature and probable sources of the problem. 3. Examine the rough-cut capacity situation using the data Jason gathered. Discuss the redults and bow they are linked to the problems identified in question 1. 3. Use the information and your knowledge of the situation to develop a complete plat for Jaion to use in the future. Part of this plan should be to build and demonstrate the approach to master scheduling for the data yiven in the oase

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock