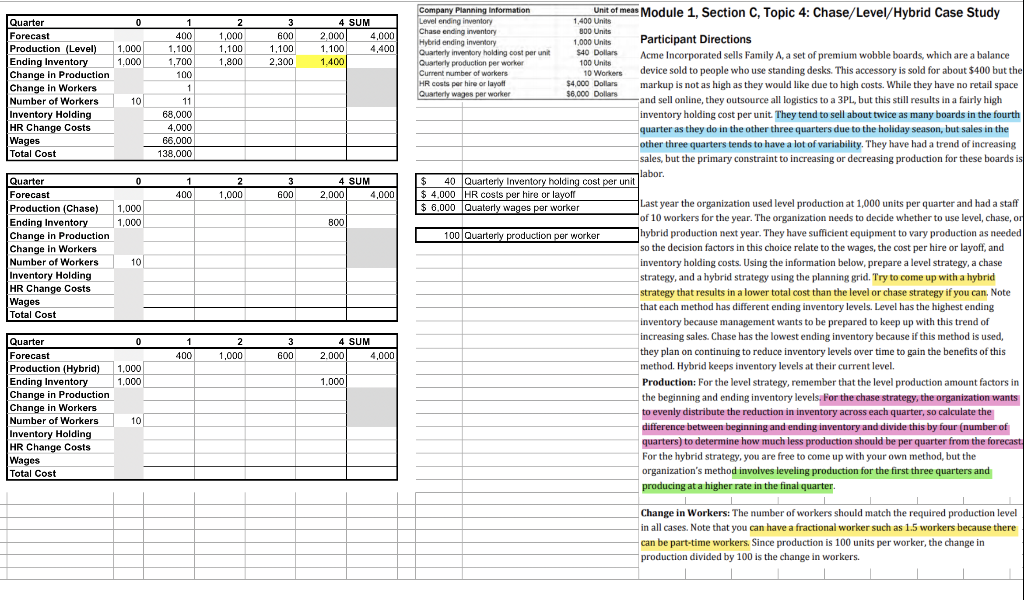

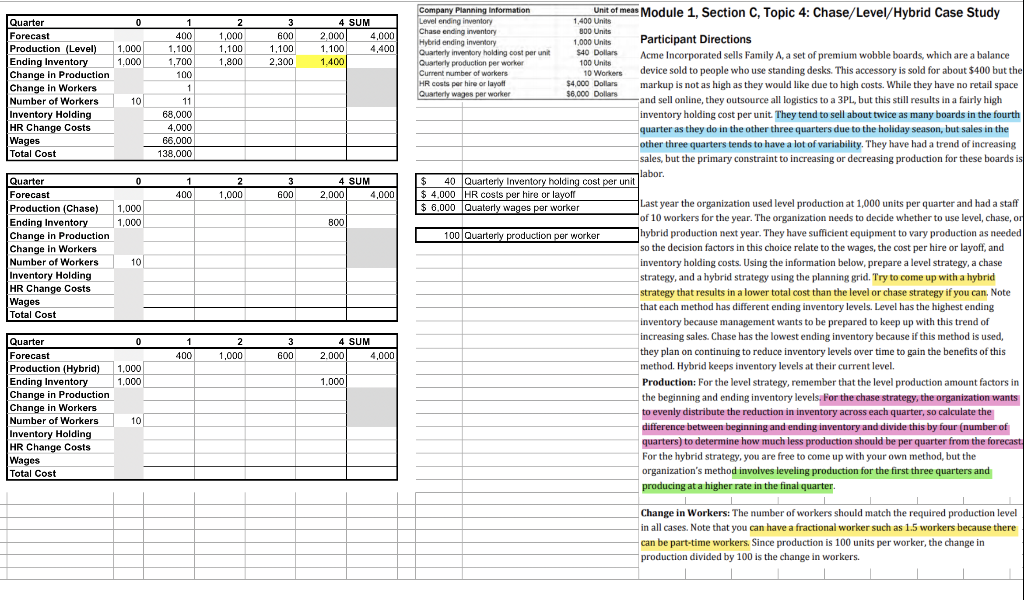

Question: Can someone help me fill out this chart please. First chart should be chase strategy, second chart level strategy and 3rd chart hybrid. 1 400

Can someone help me fill out this chart please. First chart should be chase strategy, second chart level strategy and 3rd chart hybrid.

1 400 1,100 1,700 100 1 1 2 1,000 1,100 1,800 3 600 1.100 2.300 Quarter 0 Forecast Production (Level) 1.000 Ending Inventory 1.000 Change in Production Change in Workers Number of Workers 10 Inventory Holding HR Change Costs Wages Total Cost 4 SUM 2.000 4,000 1.100 4,400 1.400 11 68,000 4,000 66,000 138,000 0 1 400 2 1,000 3 600 4 SUM 2.000 4,000 1,000 1,000 B00 Quarter Forecast Production (Chase) Ending Inventory Change in Production Change in Workers Number of Workers Inventory Holding HR Change Costs Wages Total Cost Company Planning Information Unit of meas Module 1, Section C, Topic 4: Chase/Level/Hybrid Case Study Level ending inventory 1,400 Units Chase ending inventory 800 Units Hybrid ending inventory 1,000 Units Participant Directions Quarterly inventory holding cost per un $40 Dollars Acme Incorporated sells Family A, a set of premium wobble boards, which are a balance Quarterly production per worker 100 Units Current number of workers 10 Workers device sold to people who use standing desks. This accessory is sold for about $400 but the HR costs por hire or layoff $4,000 Dollars markup is not as high as they would like due to high costs. While they have no retail space Quarterly wages per worker $8.000 Dollars and sell online, they outsource all logistics to a 3PL, but this still results in a fairly high inventory holding cost per unit. They tend to sell about twice as many boards in the fourth quarter as they do in the other three quarters due to the holiday season, but sales in the other three quarters tends to have a lot of variability. They have had a trend of increasing sales, but the primary constraint to increasing or decreasing production for these boards is labor $ 40 Quarterly Inventory holding cost per unit $ 4,000 HR costs per hire or layoff $ 6,000 Quaterly wages per worker Last year the organization used level production at 1,000 units per quarter and had a staff of 10 workers for the year. The organization needs to decide whether to use level, chase, or 100 Quarterly production per worker Jhybrid production next year. They have sufficient equipment to vary production as needed so the decision factors in this choice relate to the wages, the cost per hire or layoff, and inventory holding costs. Using the information below, prepare a level strategy, a chase strategy, and a hybrid strategy using the planning grid. Try to come up with a hybrid strategy that results in a lower total cost than the level or chase strategy if you can. Note that each method has different ending inventory levels. Level has the highest ending inventory because management wants to be prepared to keep up with this trend of increasing sales. Chase has the lowest ending inventory because if this method is used, they plan on continuing to reduce inventory levels over time to gain the benefits of this method. Hybrid keeps inventory levels at their current level. Production: For the level strategy, remember that the level production amount factors in the beginning and ending inventory levels. For the chase strategy, the organization wants to evenly distribute the reduction in inventory across each quarter, so calculate the difference between beginning and ending inventory and divide this by four (number of quarters) to determine how much less production should be per quarter from the forecast For the hybrid strategy, you are free to come up with your own method, but the organization's method involves leveling production for the first three quarters and producing at a higher rate in the final quarter. 10 0 1 2 1,000 3 600 4 SUM 2.000 4,000 400 1.000 1,000 1.000 Quarter Forecast Production (Hybrid) Ending Inventory Change in Production Change in Workers Number of Workers Inventory Holding HR Change Costs Wages Total Cost 10 Change in Workers: The number of workers should match the required production level in all cases. Note that you can have a fractional worker such as 1.5 workers because there can be part-time workers. Since production is 100 units per worker, the change in production divided by 100 is the change in workers