Question: can someone help with this question and explain in detail? thank you so much An exhaust stream exits a plant at 1atm and 160C at

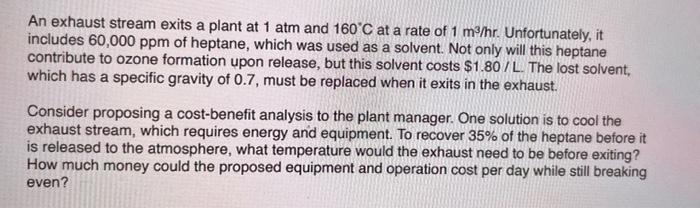

An exhaust stream exits a plant at 1atm and 160C at a rate of 1m3/hr. Unfortunately, it includes 60,000ppm of heptane, which was used as a solvent. Not only will this heptane contribute to ozone formation upon release, but this solvent costs $1.80/L. The lost solvent, which has a specific gravity of 0.7, must be replaced when it exits in the exhaust. Consider proposing a cost-benefit analysis to the plant manager. One solution is to cool the exhaust stream, which requires energy and equipment. To recover 35% of the heptane before it is released to the atmosphere, what temperature would the exhaust need to be before exiting? How much money could the proposed equipment and operation cost per day while still breaking even

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts