Question: can u please help me in this problems. :( i need to practice it but i cannot solve it properly. 1. (10 points) You have

can u please help me in this problems. :( i need to practice it but i cannot solve it properly.

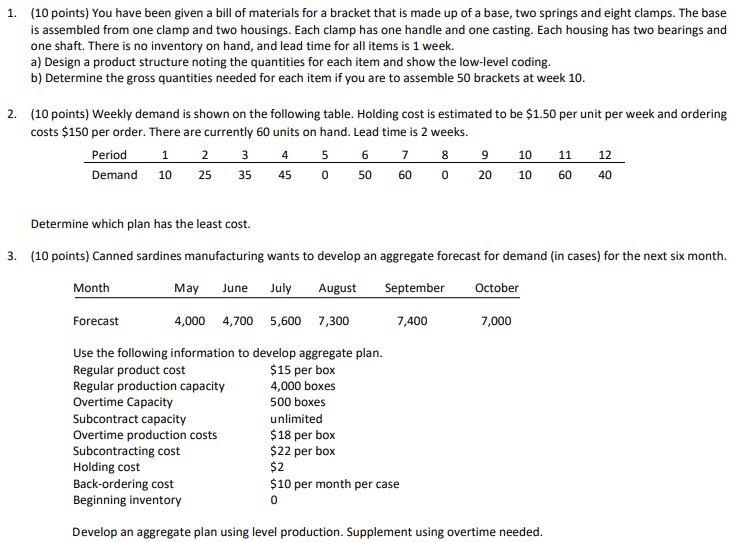

1. (10 points) You have been given a bill of materials for a bracket that is made up of a base, two springs and eight clamps. The base is assembled from one clamp and two housings. Each clamp has one handle and one casting. Each housing has two bearings and one shaft. There is no inventory on hand, and lead time for all items is 1 week. a) Design a product structure noting the quantities for each item and show the low-level coding. b) Determine the gross quantities needed for each item if you are to assemble 50 brackets at week 10. 2. (10 points) Weekly demand is shown on the following table. Holding cost is estimated to be $1.50 per unit per week and ordering costs $150 per order. There are currently 60 units on hand. Lead time is 2 weeks. Period 1 2 3 4 5 6 7 8 9 10 11 12 Demand 10 25 45 0 50 60 60 40 35 0 20 10 Determine which plan has the least cost. 3. (10 points) Canned sardines manufacturing wants to develop an aggregate forecast for demand in cases) for the next six month. Month May June July August September October Forecast 4,000 4,700 5,600 7,300 7,400 7,000 Use the following information to develop aggregate plan. Regular product cost $15 per box Regular production capacity 4,000 boxes Overtime Capacity 500 boxes Subcontract capacity unlimited Overtime production costs $18 per box Subcontracting cost $22 per box Holding cost $2 Back-ordering cost $10 per month per case Beginning inventory 0 Develop an aggregate plan using level production. Supplement using overtime needed. 1. (10 points) You have been given a bill of materials for a bracket that is made up of a base, two springs and eight clamps. The base is assembled from one clamp and two housings. Each clamp has one handle and one casting. Each housing has two bearings and one shaft. There is no inventory on hand, and lead time for all items is 1 week. a) Design a product structure noting the quantities for each item and show the low-level coding. b) Determine the gross quantities needed for each item if you are to assemble 50 brackets at week 10. 2. (10 points) Weekly demand is shown on the following table. Holding cost is estimated to be $1.50 per unit per week and ordering costs $150 per order. There are currently 60 units on hand. Lead time is 2 weeks. Period 1 2 3 4 5 6 7 8 9 10 11 12 Demand 10 25 45 0 50 60 60 40 35 0 20 10 Determine which plan has the least cost. 3. (10 points) Canned sardines manufacturing wants to develop an aggregate forecast for demand in cases) for the next six month. Month May June July August September October Forecast 4,000 4,700 5,600 7,300 7,400 7,000 Use the following information to develop aggregate plan. Regular product cost $15 per box Regular production capacity 4,000 boxes Overtime Capacity 500 boxes Subcontract capacity unlimited Overtime production costs $18 per box Subcontracting cost $22 per box Holding cost $2 Back-ordering cost $10 per month per case Beginning inventory 0 Develop an aggregate plan using level production. Supplement using overtime needed

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts