Question: can you clarify what calculations are needed for this study? Background Your organization manufactures Time-of-Flight Laser Inspection Systems. These systems perform 3-dimensional scanning using laser

can you clarify what calculations are needed for this study?

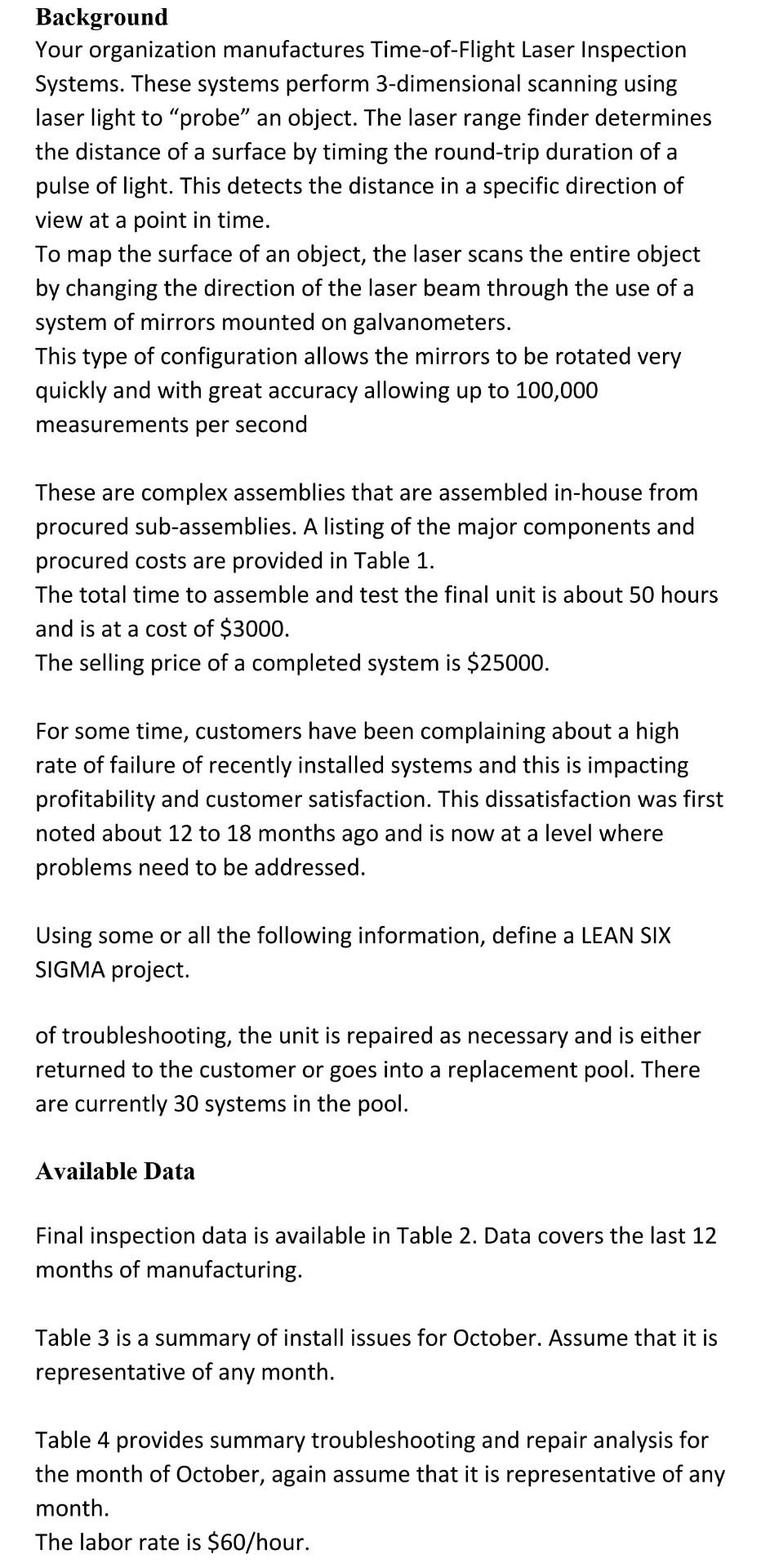

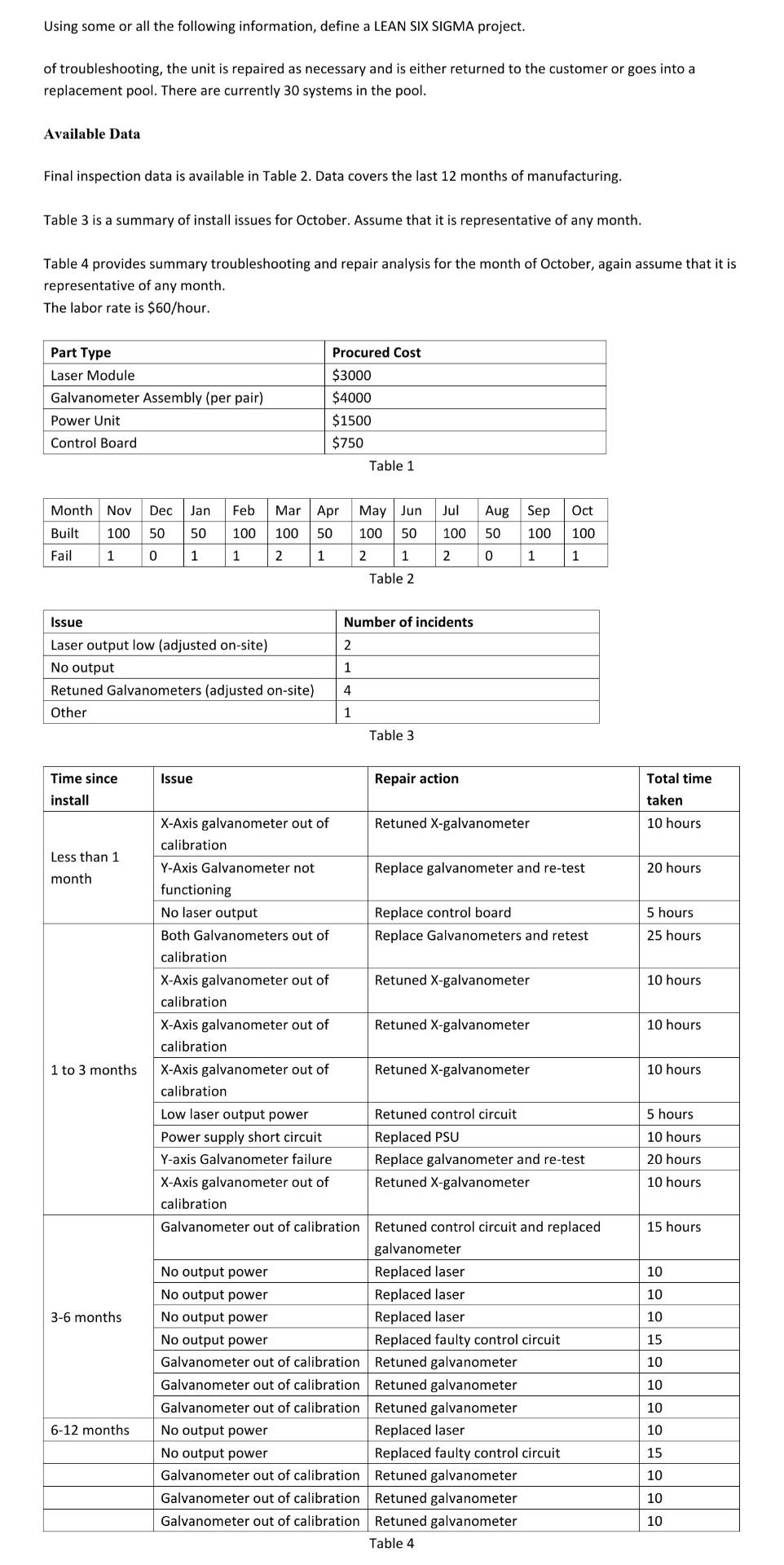

Background Your organization manufactures Time-of-Flight Laser Inspection Systems. These systems perform 3-dimensional scanning using laser light to "probe" an object. The laser range finder determines the distance of a surface by timing the round-trip duration of a pulse of light. This detects the distance in a specific direction of view at a point in time. To map the surface of an object, the laser scans the entire object by changing the direction of the laser beam through the use of a system of mirrors mounted on galvanometers. This type of configuration allows the mirrors to be rotated very quickly and with great accuracy allowing up to 100,000 measurements per second These are complex assemblies that are assembled in-house from procured sub-assemblies. A listing of the major components and procured costs are provided in Table 1. The total time to assemble and test the final unit is about 50 hours and is at a cost of $3000. The selling price of a completed system is $25000. For some time, customers have been complaining about a high rate of failure of recently installed systems and this is impacting profitability and customer satisfaction. This dissatisfaction was first noted about 12 to 18 months ago and is now at a level where problems need to be addressed. Using some or all the following information, define a LEAN SIX SIGMA project. of troubleshooting, the unit is repaired as necessary and is either returned to the customer or goes into a replacement pool. There are currently 30 systems in the pool. Available Data Final inspection data is available in Table 2. Data covers the last 12 months of manufacturing. Table 3 is a summary of install issues for October. Assume that it is representative of any month. Table 4 provides summary troubleshooting and repair analysis for the month of October, again assume that it is representative of any month. The labor rate is $60/hour. Using some or all the following information, define a LEAN SIX SIGMA project. of troubleshooting, the unit is repaired as necessary and is either returned to the customer or goes into a replacement pool. There are currently 30 systems in the pool. Available Data Final inspection data is available in Table 2. Data covers the last 12 months of manufacturing. Table 3 is a summary of install issues for October. Assume that it is representative of any month. Table 4 provides summary troubleshooting and repair analysis for the month of October, again assume that it is representative of any month. The labor rate is $60/hour. Part Type Laser Module Galvanometer Assembly (per pair) Power Unit Control Board Issue Laser output low (adjusted on-site) No output Month Nov Dec Jan Feb Mar Apr Built 100 50 50 100 100 50 Fail 1 0 1 1 2 1 Retuned Galvanometers (adjusted on-site) Other Time since install Less than 1 month 1 to 3 months 3-6 months 6-12 months Issue X-Axis galvanometer out of calibration Y-Axis Galvanometer not functioning No laser output Both Galvanometers out of calibration. X-Axis galvanometer out of calibration X-Axis galvanometer out of calibration X-Axis galvanometer out of calibration Procured Cost $3000 $4000 $1500 $750 No output power No output power No output power 2 1 4 1 Table 1 May Jun 100 50 2 1 Table 2 Number of incidents No output power Galvanometer out of calibration Galvanometer out of calibration Galvanometer out of calibration No output power No output power Galvanometer out of calibration Galvanometer out of calibration Galvanometer out of calibration Jul Aug 100 50 0 Table 3 2 Repair action Sep Oct 100 100 1 1 Retuned X-galvanometer Replace galvanometer and re-test Replace control board Replace Galvanometers and retest Retuned X-galvanometer Retuned X-galvanometer Low laser output power Power supply short circuit Y-axis Galvanometer failure X-Axis galvanometer out of calibration Galvanometer out of calibration Retuned control circuit and replaced galvanometer Replaced laser Replaced laser Replaced laser Retuned X-galvanometer Retuned control circuit Replaced PSU Replace galvanometer and re-test Retuned X-galvanometer Replaced faulty control circuit Retuned galvanometer Retuned galvanometer Retuned galvanometer Replaced laser Replaced faulty control circuit Retuned galvanometer Retuned galvanometer Retuned galvanometer Table 4 Total time taken 10 hours 20 hours 5 hours 25 hours 10 hours 10 hours 10 hours 5 hours 10 hours 20 hours 10 hours 15 hours 10 10 10 15 10 10 10 10 15 10 10 10Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock