Question: Can you make a summary for these two pages please? Thank you mounseur/mademoiselle I Spray booth RIA ASSY, COMPLESS BRAKES 1-2 TON TRUCK No af

Can you make a summary for these two pages please? Thank you mounseur/mademoiselle

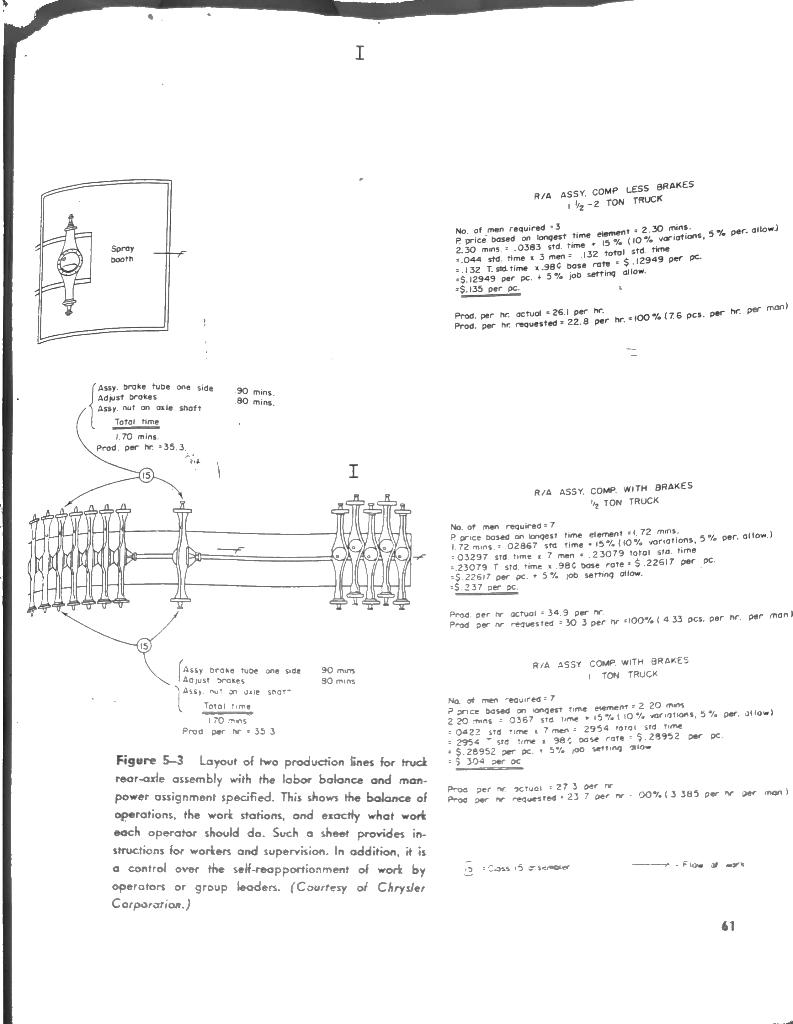

I Spray booth RIA ASSY, COMPLESS BRAKES 1-2 TON TRUCK No af men required. 3 P price based on longest time element. 2.30 mins 230 mins .0383 Std. time. 15% (10% variations, 5% per gilow 2.044 std time 1 3 men = 132 total std time -132 Tst time x_986 bose note - $.12949 per pc. $.12949 per pc. + 5% job setting allow. - $.135 per pc Prod. per the actual = 26.1 per hr. Prod. per he requested 22.8 per hr. 100% 176 pcs. per hr. per man) 90 mins. 80 mins. Assy. broke tube one side Adjust brokes Assy. nut on oxie shoft Total time 1.70 mins Prod per he 35.3. 15 I R/A ASSY COMP WITH BRAKES TON TRUCK No. of men required 7 Price based on longest time element 4.72 mins. 1.72 mins. 02867 Sto time. 15% 10% vorations, 5per allow) - 03297 sid tume 7 man 23079 total statime +23079 T stdtime.980 Dose pate. $.22617 per pc = $ 22617 per pc. 5% job setting allow =$ 237 perc Prod ber he actual = 34.9 per ne Prod per requested 30 3 per nr 100% ( 433 pcs. per m. per man 90 murs 30 mins R/A ASSY COMP WITH BRAKES 1 TON TRUCK Assy brane tube one side Adjust brokes ASS) Nyt on Jule SOT Total time 170 ms Prod per pr 353 No. of men required=7 Price based on ongest time evement - 2 20 mins 2 20 mins. 0367 std lime 15% 10% varigton, 5% per allow) - Od 22 std time 7 mer: 2954 FOTO srd Time = 2954 ste mesec bose rare $.29952 per pc $.28952 per pc 5% 10 setting - $ 304 per og Prosper TUGI : 273 per Proe per requested. 23 7 per - 00%(3 385 per per mon Figure 53 Layout of two production lines for truck rear axle assembly with the labor bolonce and man- power ossignment specified. This shows the balance of operations, the work stations, and exactly what work each operator should do. Such a sheet provides in- structions for workers and supervision. In addition, it is a control over the self-reapportionment of work by operators or group leaders. (Courtesy of Chrysler Corporation) F - 0.935 15 Serier 61 in a way that allows, say, only one hour's material the organization, the layout man should be sure 10 be at a given workplace (see Figure 5-4). At that the people involved can be "relocated." Om the same time, they realize that workers paid an very effective layout failed completely because incentive which is based on output will increase each process foreman retained supervisory contro that over-all output as the length of time of each over his men when they were moved into an as task is shortened. The delivery of one hour's mate- sembly line. Obviously the line could not operate rial takes advantage of this, by giving each man as a unit. a number of short tasks. he can make a spurt In cases of conversion from one basic type of toward the end of each task. layout to another, the layout may call for a com There have frequently been feelings among plete change in the state of mind of the entire workers that they do not like certain layouts. Pro- organization. For example, the supervision in duction lines have come in for their share of per- steel mill is often assigned on an area basis-cach sonal dislike or praise. Some workers like them; supervisor having charge of so many bays of the others do not. Workers' dislike of the production building. With improved equipment, a relayout of Tine includes these points: it limits personal out- the area might call for a series of process depart. put, restricts opportunity for self-improvement, ments. Now each man supervises a number of discourages sense of security, paces rate of work. similar machines or equipment. Some of the then and reduces personal freedom. On the other hand, may not understand why they now have less area many workers prefer line production: the work is to supervise; others may feel they are being usually easier, more companionable, more uni- called on for responsibility over too large an area Change-overs from process layout or fixed. form, more regular or steady, and requires less planning and mental work. position layout to production lines are typical of Organization and Supervision. The best lay- cases where management's philosophy must be out is useless if it does not fit the organization of altered. With lines, each supervisor will have to the company. Actually, an organization chart think in terms of one type of product and several itself often establishes what the over-all layout types of operations instead of one operation and plan should be like. Layout men should examine several products. This change can cause a virtual the company organization chart in planning their revolution in any plant. It will involve planners layout. This is especially true in relayout work. and schedulers, buyers, inspection force, main. Any layout that calls for a reassignment of duties tenance men, and others, and it may change their and responsibilities by certain foremen should be methods of operation materially. carefully considered. It may give one foreman a Frequently a layout plan calls for two or three lot more work so that he has to have an assistant decentralized supporting activities such as inspec- which he does not want: it may lower the prestige tion. This may cause three times the investment of another foreman by taking half his former in aspection supervision than would be the case number of workers away from him. in one centralized inspection activity. While we Layout men should never assume that the men rightly place our emphasis on material flow and involved can adjust themselves to the new layout short distances, we can lose sight of economies in without difficulty. Sometimes they can; sometimes supervision when not aware that we should con- they will need help; occasionally they may have to sider them. Certainly when a day's production of be replaced. One man has more diversified experi- several operators can be carried by hand to a cen- eace than is necessary, another needs more train- tral inspection area, the elements of distance and ing. In every case, where the new layout calls for flow rose much of their significance. adjustment in the supervisory or other parts of Cier point was the top management of Fra: a further discussion of this, see the R their freact*th leart trouble may want Line Technique." McGraw-Hill Hook Company, 1947 Praca: eginers is located on the ground floor; I Factors influencing Plant Layout 62

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts