Question: Can you please explain as much as possible like if I had zero Knowledge on this subject? PLEASE The bill of materials (BOM) for product

Can you please explain as much as possible like if I had zero Knowledge on this subject? PLEASE

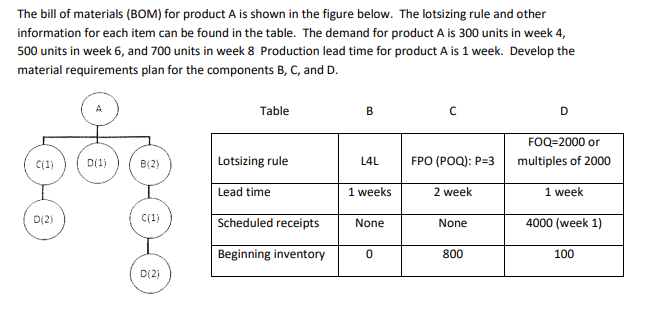

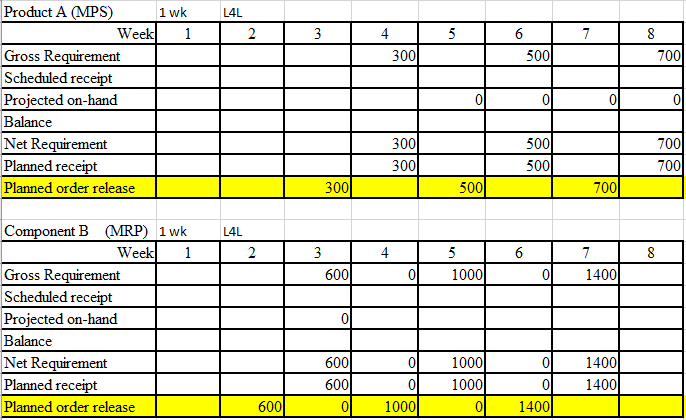

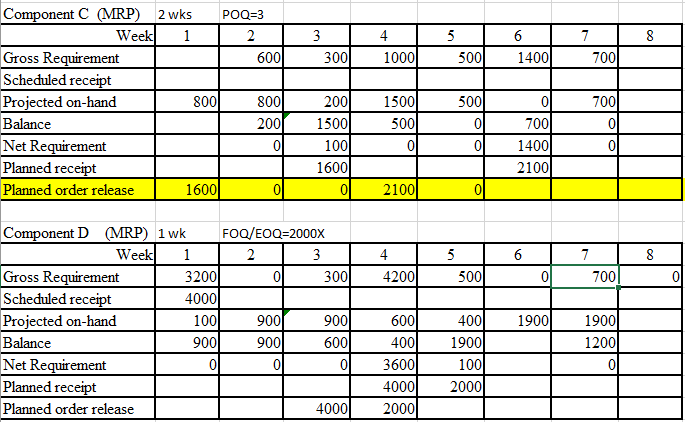

The bill of materials (BOM) for product A is shown in the figure below. The lotsizing rule and other information for each item can be found in the table. The demand for product A is 300 units in week 4, 500 units in week 6, and 700 units in week 8 Production lead time for product A is 1 week. Develop the material requirements plan for the components B, C, and D. Table B D FOQ=2000 or multiples of 2000 C(1) D11) B[2) Lotsizing rule L4L FPO (POQ): P=3 Lead time 1 weeks 2 week 1 week D 2) C(1) Scheduled receipts None None 4000 (week 1) Beginning inventory 0 800 100 D(2) L4L 2 3 5 7 4 3001 6 5001 8 700 Product A (MPS) 1 wk Week 1 Gross Requirement Scheduled receipt Projected on-hand Balance Net Requirement Planned receipt Planned order release 3001 300 5001 500 700 700 3001 5001 700 L4L 2 4 6 8 3 600 5 10001 7 1400 0 0 Component B (MRP) 1wk Week 1 Gross Requirement Scheduled receipt Projected on-hand Balance Net Requirement Planned receipt Planned order release 0 0 0 6001 600 0 10001 1000 0 14001 1400 0 1000 0 6001 14001 POQ=3 3 8 2 600 4 1000 5 5001 6 1400 7 700 3001 Component C (MRP) 2 wks Week) 1 Gross Requirement Scheduled receipt Projected on-hand 8001 Balance Net Requirement Planned receipt Planned order release 1600 1500 0 800 200 0 5001 0 700 0 5001 700V 2001 15001 1001 16001 0 0 0 1400 2100 0 2100 6 8 4 4200 5 5001 7 700 0 0 Component D (MRP) 1 wk FOQ/EOQ=2000X Week 1 2 3 Gross Requirement 3200 0 3001 Scheduled receipt 4000 Projected on-hand 100 900 9001 Balance 900 9001 600 Net Requirement 0 0 0 Planned receipt Planned order release 40001 1900 1900 1200 6001 4001 3600 4000 2000 4001 19001 1001 20001Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts