Question: Can you solve this one? I'm just having a hard time knowing how did he get these required machine hours, available machine effective capacity and

Can you solve this one? I'm just having a hard time knowing how did he get these required machine hours, available machine effective capacity and number of machines required. Explain if too if possible. Thanks a lot!

Can you solve this one? I'm just having a hard time knowing how did he get these required machine hours, available machine effective capacity and number of machines required. Explain if too if possible. Thanks a lot!

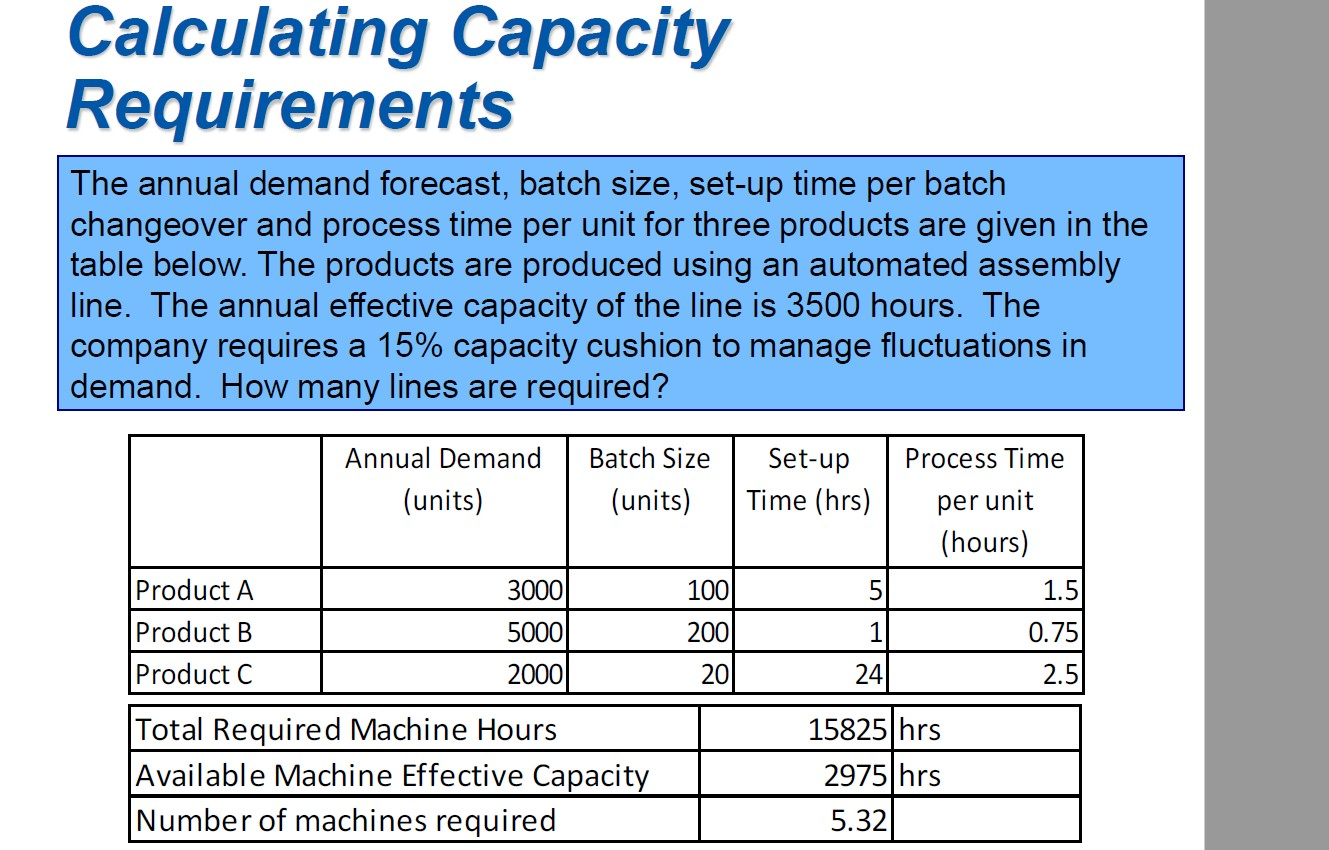

Calculating Capacity Requirements The annual demand forecast, batch size, set-up time per batch changeover and process time per unit for three products are given in the table below. The products are produced using an automated assembly line. The annual effective capacity of the line is 3500 hours. The company requires a 15% capacity cushion to manage fluctuations in demand. How many lines are required? Process Time Annual Demand (units) Batch Size (units) Set-up Time (hrs) per unit 3000 100 5 Product A Product B Product C (hours) 1.5 0.75 5000 1 200 20 2000 24 2.5 Total Required Machine Hours Available Machine Effective Capacity Number of machines required 15825 hrs 2975 hrs 5.32

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock