Question: Case 6 Chapter 6 Process and Facility Layout Producing RoundUp weed sprayers involves fourteen production tasks, lettered a through n.below. For each task, the time

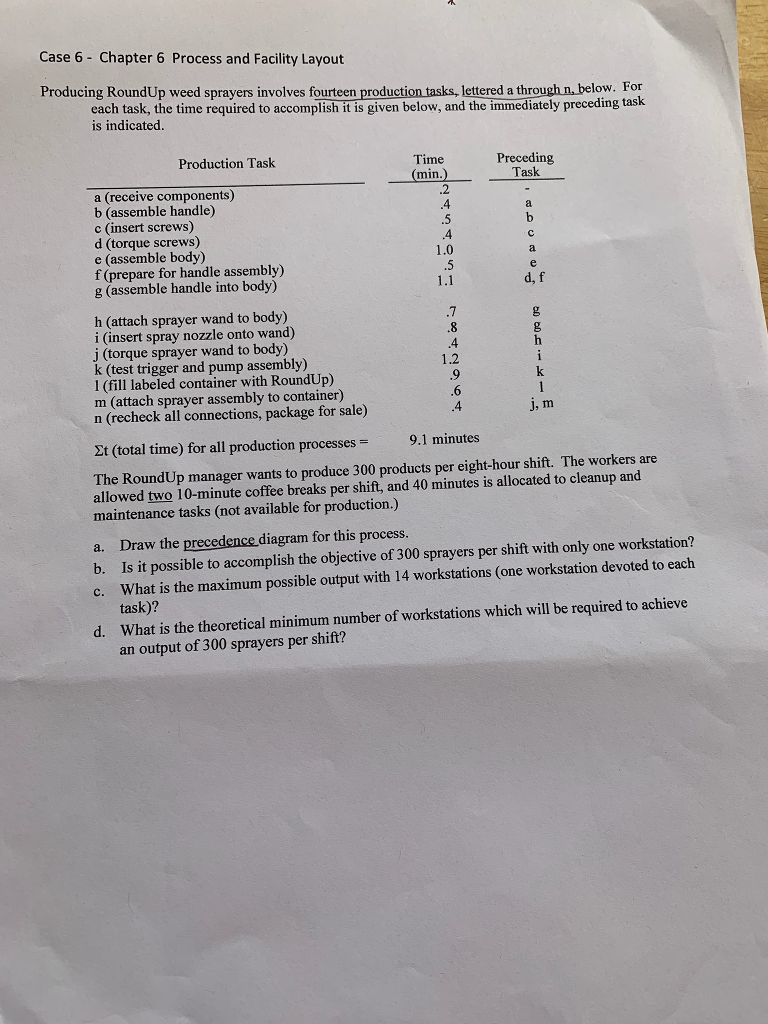

Case 6 Chapter 6 Process and Facility Layout Producing RoundUp weed sprayers involves fourteen production tasks, lettered a through n.below. For each task, the time required to accomplish it is given below, and the immediately preceding task is indicated Production Task Time min.) .2 4 Preceding a (receive components) b (assemble handle) c (insert screws) d (torque screws) e (assemble body) f (prepare for handle assembly) g (assemble handle into body) .4 1.0 d, f h (attach sprayer wand to body) i (insert spray nozzle onto wand) j (torque sprayer wand to body) k (test trigger and pump assembly) 1 (fill labeled container with RoundUp) m (attach sprayer assembly to container) n (recheck all connections, package for sale) .8 .4 1.2 .4 J, m 2t (total time) for all production processes9.1 minutes The RoundUp manager wants to produce 300 products per eight-hour shift. The workers are allowed two 10-minute coffee breaks per shift, and 40 minutes is allocated to cleanup and maintenance tasks (not available for production.) Draw the precedence diagram for this process. Is it possible to accomplish the objective of 300 sprayers per shift with only one workstation? What is the maximum possible output with 14 workstations (one workstation devoted to each task)? What is the theoretical minimum number of workstations which will be required to achieve an output of 300 sprayers per shift? a. b. c. d. Case 6 Chapter 6 Process and Facility Layout Producing RoundUp weed sprayers involves fourteen production tasks, lettered a through n.below. For each task, the time required to accomplish it is given below, and the immediately preceding task is indicated Production Task Time min.) .2 4 Preceding a (receive components) b (assemble handle) c (insert screws) d (torque screws) e (assemble body) f (prepare for handle assembly) g (assemble handle into body) .4 1.0 d, f h (attach sprayer wand to body) i (insert spray nozzle onto wand) j (torque sprayer wand to body) k (test trigger and pump assembly) 1 (fill labeled container with RoundUp) m (attach sprayer assembly to container) n (recheck all connections, package for sale) .8 .4 1.2 .4 J, m 2t (total time) for all production processes9.1 minutes The RoundUp manager wants to produce 300 products per eight-hour shift. The workers are allowed two 10-minute coffee breaks per shift, and 40 minutes is allocated to cleanup and maintenance tasks (not available for production.) Draw the precedence diagram for this process. Is it possible to accomplish the objective of 300 sprayers per shift with only one workstation? What is the maximum possible output with 14 workstations (one workstation devoted to each task)? What is the theoretical minimum number of workstations which will be required to achieve an output of 300 sprayers per shift? a. b. c. d

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts