Question: Case Examination and Analysis with a focus on practical application of the topics studied in the course. 2. Literature review on using IoT in supply

Case Examination and Analysis with a focus on practical application of the topics studied in the course.

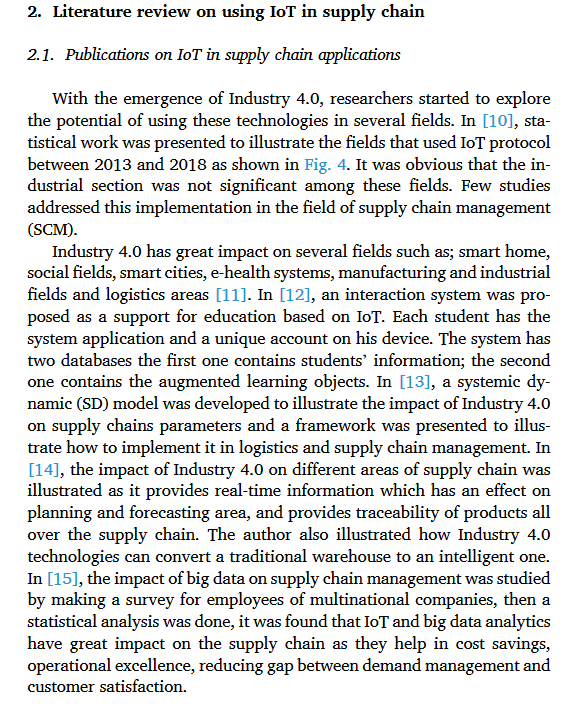

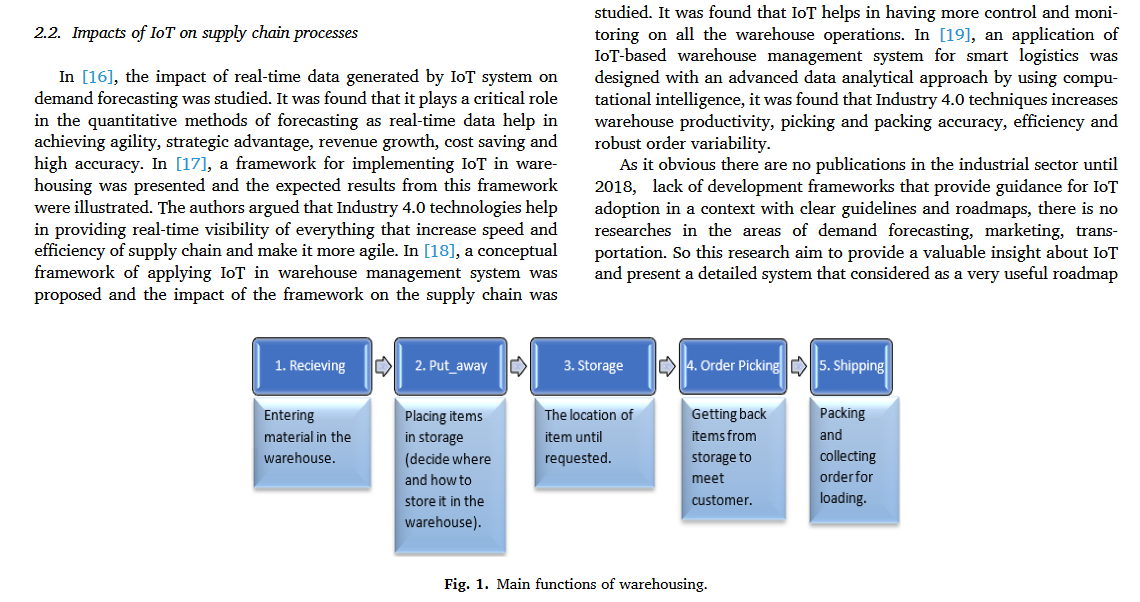

2. Literature review on using IoT in supply chain 2.1. Publications on IoT in supply chain applications With the emergence of Industry 4.0, researchers started to explore the potential of using these technologies in several fields. In [10], statistical work was presented to illustrate the fields that used IoT protocol between 2013 and 2018 as shown in Fig. 4. It was obvious that the industrial section was not significant among these fields. Few studies addressed this implementation in the field of supply chain management (SCM). Industry 4.0 has great impact on several fields such as; smart home, social fields, smart cities, e-health systems, manufacturing and industrial fields and logistics areas [11]. In [12], an interaction system was proposed as a support for education based on IoT. Each student has the system application and a unique account on his device. The system has two databases the first one contains students' information; the second one contains the augmented learning objects. In [13], a systemic dynamic (SD) model was developed to illustrate the impact of Industry 4.0 on supply chains parameters and a framework was presented to illustrate how to implement it in logistics and supply chain management. In [14], the impact of Industry 4.0 on different areas of supply chain was illustrated as it provides real-time information which has an effect on planning and forecasting area, and provides traceability of products all over the supply chain. The author also illustrated how Industry 4.0 technologies can convert a traditional warehouse to an intelligent one. In [15], the impact of big data on supply chain management was studied by making a survey for employees of multinational companies, then a statistical analysis was done, it was found that IoT and big data analytics have great impact on the supply chain as they help in cost savings, operational excellence, reducing gap between demand management and customer satisfaction. 2.2. Impacts of IoT on supply chain processes In [16], the impact of real-time data generated by IoT system on demand forecasting was studied. It was found that it plays a critical role in the quantitative methods of forecasting as real-time data help in achieving agility, strategic advantage, revenue growth, cost saving and high accuracy. In [17], a framework for implementing IoT in warehousing was presented and the expected results from this framework were illustrated. The authors argued that Industry 4.0 technologies help in providing real-time visibility of everything that increase speed and efficiency of supply chain and make it more agile. In [18], a conceptual framework of applying IoT in warehouse management system was proposed and the impact of the framework on the supply chain was studied. It was found that IoT helps in having more control and monitoring on all the warehouse operations. In [19], an application of IoT-based warehouse management system for smart logistics was designed with an advanced data analytical approach by using computational intelligence, it was found that Industry 4.0 techniques increases warehouse productivity, picking and packing accuracy, efficiency and robust order variability. As it obvious there are no publications in the industrial sector until 2018, lack of development frameworks that provide guidance for IoT adoption in a context with clear guidelines and roadmaps, there is no researches in the areas of demand forecasting, marketing, transportation. So this research aim to provide a valuable insight about IoT and present a detailed system that considered as a very useful roadmap Fig. 1. Main functions of warehousing. W. Hamdy et al. Sustainable Futures 4 (2022) 100069 Fig. 4. Number of publication of IoT in several fields [10]. for academics and practitioners to show how they can implement ioT in supply chains and gain more benefits from it then present a numerical interaction, proactive maintenance and reducing costs. IoT can have a significant role in improving various functions of SCM. Fig. 6 summarizes some potential benefits of this implementation [23]. IoT provides a solution based on hardware and software that can receive, retrieve, process, and store data according to the configured processes using some technologies and protocols such as: RFID which is one of the most important technologies used when applying IoT. It is used for identifying objects with a unique ID and it can be used for storing data about the products attached. Wireless Sensor Network (WSN) that is considered as an important advantage of IoT. It depends on sensors that can be attached to any object and has the ability to collect, monitor and analyze data. These technologies and sensors can be used in inventory management to monitor, track, trace and provide real-time visibility of all objects. Hence it provides more control, accuracy and competitive advantages to enterprises [24]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts