Question: Case Questions Using the Product Forecasting Information that has been provided from FY2017 through FY2020 (four years), calculate the measures of forecast accuracy (MFE, MAD,

Case Questions

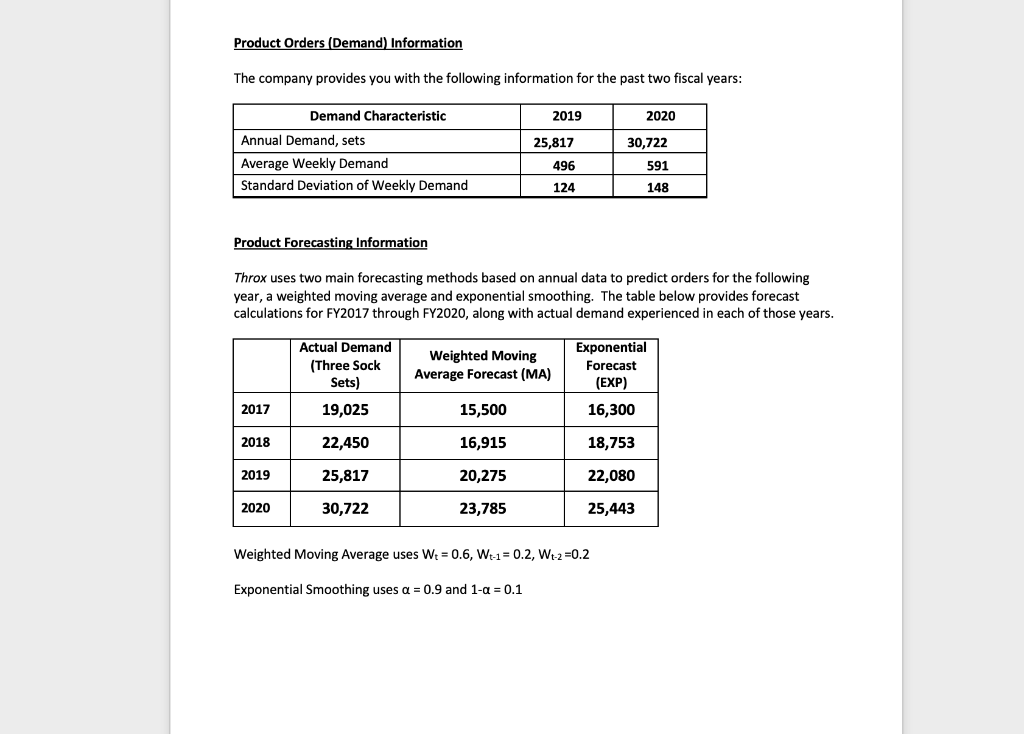

Using the Product Forecasting Information that has been provided from FY2017 through FY2020 (four years), calculate the measures of forecast accuracy (MFE, MAD, and MAPE) for the Weighted Moving Average (MA) and the Exponential Smoothing (EXP) approaches to forecasting.

What are the values of MFE, MAD, and MAPE for each of these two approaches to forecasting (MA and EXP)? Which of the approaches is more accurate?

Do these forecasts seem adequate for the purposes of decision making? Why or why not?

Note: Unlike your homework/exams where we utilized multiple months, this is just for the four years (treat them like months).

Develop forecasts for FY2021 using the two forecasting methods currently employed by Throx.

What are the forecast values that you calculated for each? Please be sure to show work.

Based on your assessments of forecast accuracy from Q1, which of the forecasts would be more appropriate to support decisions you may need to make?

Are there other considerations that you would recommend to Throx.

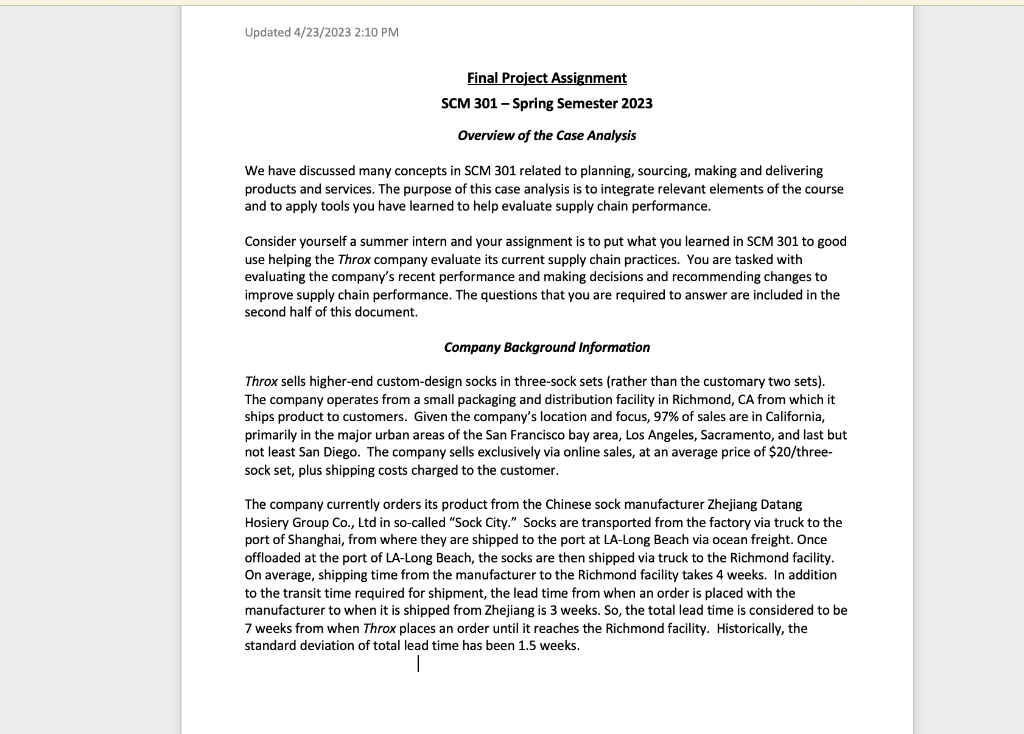

Updated 4/23/2023 2:10 PM Final Project Assignment SCM 301 - Spring Semester 2023 Overview of the Case Analysis We have discussed many concepts in SCM 301 related to planning, sourcing, making and delivering products and services. The purpose of this case analysis is to integrate relevant elements of the course and to apply tools you have learned to help evaluate supply chain performance. Consider yourself a summer intern and your assignment is to put what you learned in SCM 301 to good use helping the Throx company evaluate its current supply chain practices. You are tasked with evaluating the company's recent performance and making decisions and recommending changes to improve supply chain performance. The questions that you are required to answer are included in the second half of this document. Company Background Information Throx sells higher-end custom-design socks in three-sock sets (rather than the customary two sets). The company operates from a small packaging and distribution facility in Richmond, CA from which it ships product to customers. Given the company's location and focus, 97% of sales are in California, primarily in the major urban areas of the San Francisco bay area, Los Angeles, Sacramento, and last but not least San Diego. The company sells exclusively via online sales, at an average price of $20/three- sock set, plus shipping costs charged to the customer. The company currently orders its product from the Chinese sock manufacturer Zhejiang Datang Hosiery Group Co., Ltd in so-called "Sock City." Socks are transported from the factory via truck to the port of Shanghai, from where they are shipped to the port at LA-Long Beach via ocean freight. Once offloaded at the port of LA-Long Beach, the socks are then shipped via truck to the Richmond facility. On average, shipping time from the manufacturer to the Richmond facility takes 4 weeks. In addition to the transit time required for shipment, the lead time from when an order is placed with the manufacturer to when it is shipped from Zhejiang is 3 weeks. So, the total lead time is considered to be 7 weeks from when Throx places an order until it reaches the Richmond facility. Historically, the standard deviation of total lead time has been 1.5 weeks. |

Step by Step Solution

There are 3 Steps involved in it

To tackle the questions lets go stepbystep Step 1 Calculate MFE MAD and MAPE Definitions Mean Foreca... View full answer

Get step-by-step solutions from verified subject matter experts