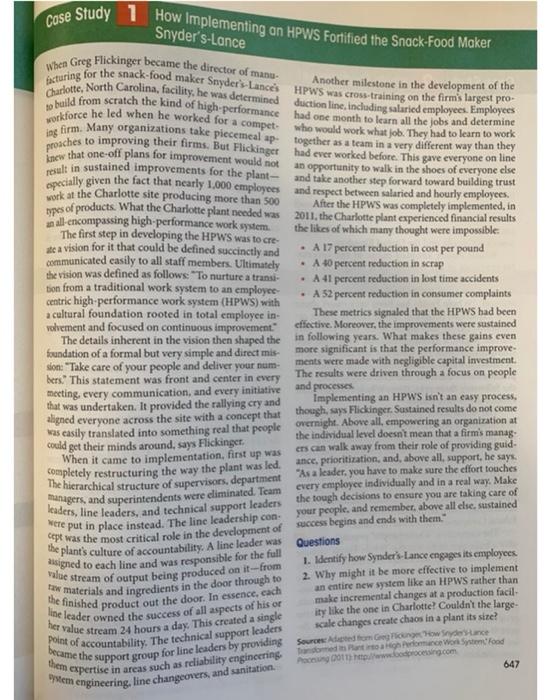

Case Study 1 How Implementing an HPWS Fortified the Snack-Food Maker Snyder's-Lance an When Greg Flickinger became the director of mang facturing for the snack-food maker Snyder's Lances HPWS was cross-training on the firm's largest pro- Charlotte, North Carolina, facility, he was determined Another milestone in the development of the to build from scratch the kind of high-performance had one month to learn all the jobs and determine workforce he led when he worked for a compet duction line, including salaried employees. Employees ing firm. Many organizations take piecemeal ap who would work what job. They had to learn to work proaches to improving their firms. But Flickinger had ever worked before. This gave everyone on line together as a team in a very different way than they knew that one-off plans for improvement would not result in sustained improvements for the plant- an opportunity to walk in the shoes of everyone else and take another step forward toward building trust work at the Charlotte site producing more than 500 and respect between salaried and hourly employees opes of products. What the Charlotte plant needed was After the HPWS was completely implemented, in all encompassing high-performance work system. 2011, the Charlotte plant experienced financial results The first step in developing the HPWS was to cre- the likes of which many thought were impossible ste a vision for it that could be defined succinctly and A 17 percent reduction in cost per pound communicated easily to all staff members. Ultimately A 40 percent reduction in scrap the vision was defined as follows: "To nurture a transi tion from a traditional work system to an employee A 41 percent reduction in lost time accidents centric high-performance work system (HPWS) with A 52 percent reduction in consumer complaints a cultural foundation rooted in total employee in These metrics signaled that the HPWS had been volvement and focused on continuous improvement." cffective. Moreover, the improvements were sustained The details inherent in the vision then shaped the in following years. What makes these gains even foundation of a formal but very simple and direct mis- more significant is that the performance improve sion: "Take care of your people and deliver your num ments were made with negligible capital investment. bers." This statement was front and center in every The results were driven through a focus on people meeting, every communication, and every initiative and processes that was undertaken. It provided the rallying cry and Implementing an HPWS isn't an easy process, aligned everyone across the site with a concept that though, says Flickinger . Sustained results do not come was easily translated into something real that people overnight. Above all , empowering an organization at the individual level doesn't mean that a firm's manag- could get their minds around, says Flickinger ers can walk away from their role of providing guid- When it came to implementation, first up was ance, prioritization, and, above all, support, he says. completely restructuring the way the plant was led. "As a leader, you have to make sure the effort touches The hierarchical structure of supervisors, department every employee individually and in a real way. Make hanagers and superintendents were eliminated Team the tough decisions to ensure you are taking care of leaders, line leaders, and technical support leaders your people, and remember, above all else, sustained were put in place instead. The line leadership con success begins and ends with them." cept was the most critical role in the development of Questions the slant's culture of accountability. A line leader was signed to each line and was responsible for the full 1. Identify how Synder's-Lance engages its employees value stream of output being produced on it-from 2. Why might it be more effective to implement raw materials and ingredients in the door through to an entire new system like an HPWS rather than the finished product out the door. In essence, cach make incremental changes at a production facil line leader owned the success of all aspects of his or ity like the one in Charlotte Couldn't the large- her value stream 24 hours a day. This created a single scale changes create chaos in a plant its site! Point of accountability. The technical support leaders became the support group for line leaders by providing Sourced from going How Since orded the Won System Kood 647 ystem engineering, line changeovers, and sanitation them Pache.processing.com expertise in areas such as reliability engineering