Question: Case study 4.1 Define phase This study is performed at one of the plants in Y Company. This plant is named wafer biscuit plant. It

Case study

4.1 Define phase

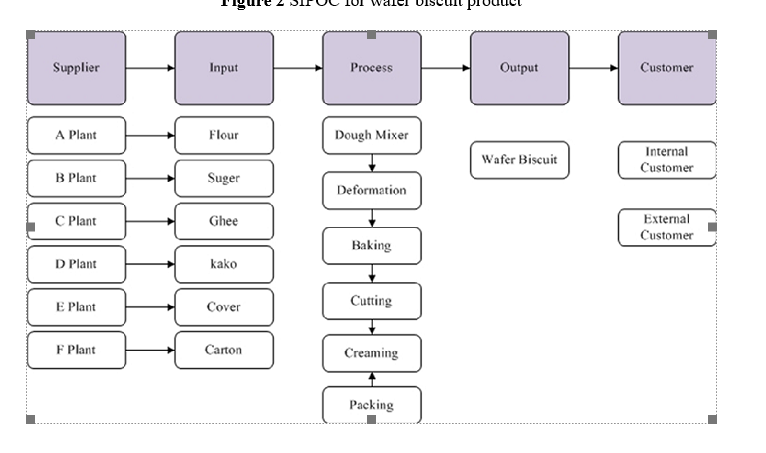

This study is performed at one of the plants in Y Company. This plant is named wafer biscuit plant. It has one production line, which is producing only wafer biscuits. In recent years, there is an increasing demand of flour in wafer biscuit production line. The increasing rate is 28% per month. Where the flour is a primary ingredient of wafer products (2535% of product weight). This problem causes large scrap quantity and increasing intangible loss and greatly enhances the production cost. Therefore, the company cannot achieve the best level. The problem statement is to reduce the deviation of flour usage in wafer biscuit production line. Thus, the CTQ of this case study is that the total deviation of flour usage should not exceed 5% per month. A SIPOC diagram is used to show the path of product from supplier to customer. We defined the suppliers as unknown companies. The input materials of wafer biscuit process are flour, sugar, ghee, kako, cover and carton. The essential elements of the process are dough mixer, deformation, baking, cutting, creaming and packing. Then, the output is a final wafer biscuit product. Finally, there are two customers, which are internal and external customers. Figure 2 illustrates the SIPOC diagram for wafer biscuit product.

Figure 2 SIPOC for wafer biscuit product

Next, the process flow is designed to provide a complete depicted sequence of steps in order to determine the flow in the process and opportunities for improvement.

4.2 Measure phase

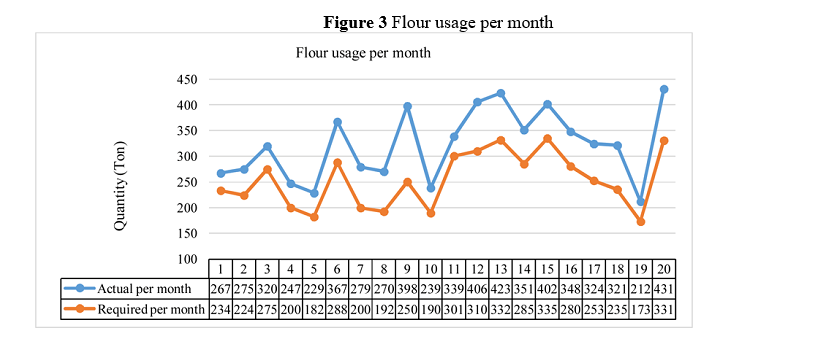

The data were collected for the wafer production line from 1st December, 2013 to 30 July, 2015. Totally, the data have been gathered for 20 months. The data consist in the required and the actual quantities of flour used per month and flour deviation rate between them. The flour deviation rate is termed as the difference between

the actual and required. Figure 3 shows the flour usage per month during the period. The figure shows that the required quantities per month are different because the monthly demand is different. Moreover, there is a high deviation from required value. That is to say, there is a lost in flour usage per month. The capability of the

process has been evaluated using process capability analysis based on flour deviation rate. The results show that a substantial part of process output will be out of specifications. Therefore, the results recommend that more efforts are required to reduce the flour deviation rate.

Figure 3 Flour usage per month

4.3 Analysis phase

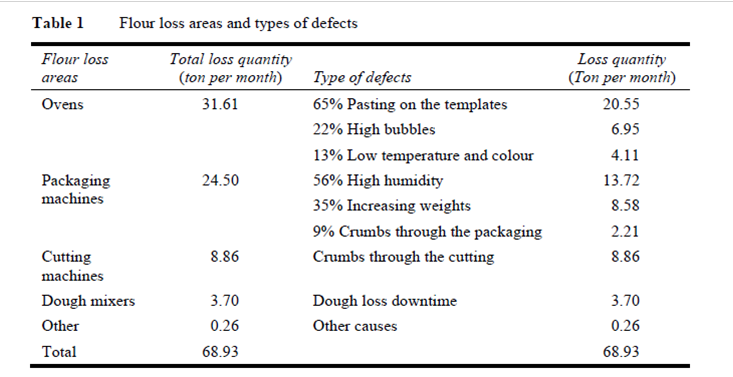

In this section, the problem is analysed in order to determine the root causes and reduce the gap between required and the actual quantities of the flour used per month. To do this, first, we have identified flour loss areas with lost quantities and their types of defects in the production line, as shown in Table 1.

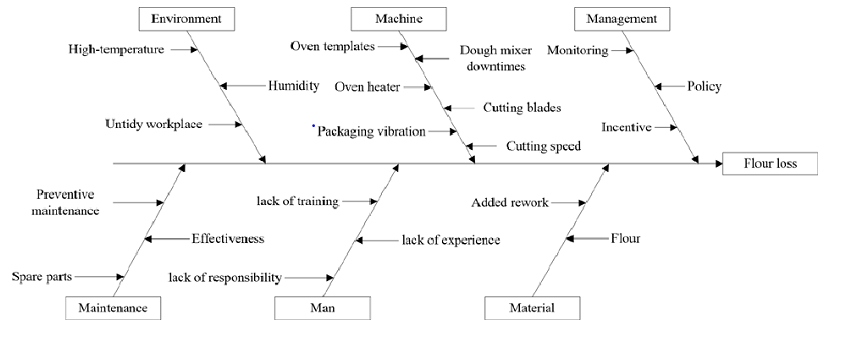

The analysis was performed to find the root cause(s) of the problem. Brainstorming session based on the experiences of management and improvement team members was conducted to identify possible causes of these defects. The cause-and-effect diagram was constructed to illustrate and categorize the possible causes of the problem. Once finished, the diagram assisted to find the root causes and provided improvement ideas. In general, six main categories are used in a cause-and-effect diagram, which are material, man, maintenance, management, machine and environment. The brainstormed root causes are presented in the cause-and-effect diagram that shown in Figure 4. Through the analysis of diagram, we can assess that the main causes of flour loss are:

- oven templates and heaters

- cutting blades and speed

- packaging vibration

- dough mixer downtimes

- added rework

- the temperature of work boundaries

- lack of preventive maintenance

- lack of regular inspection equipment.

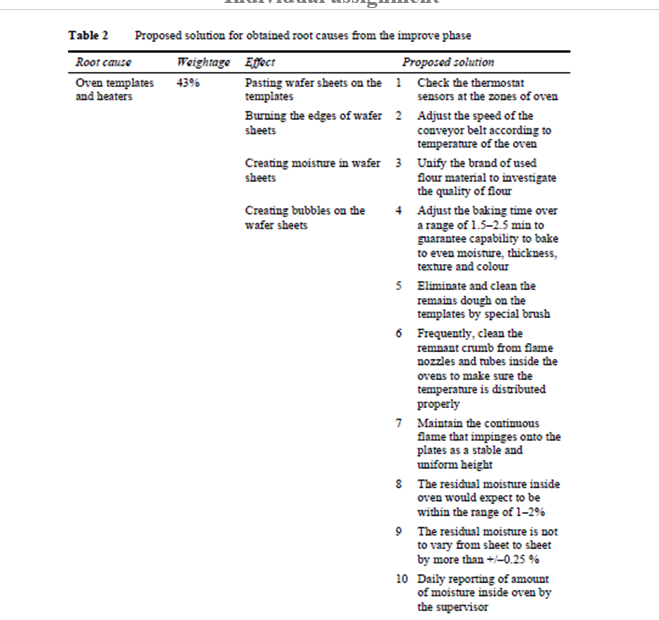

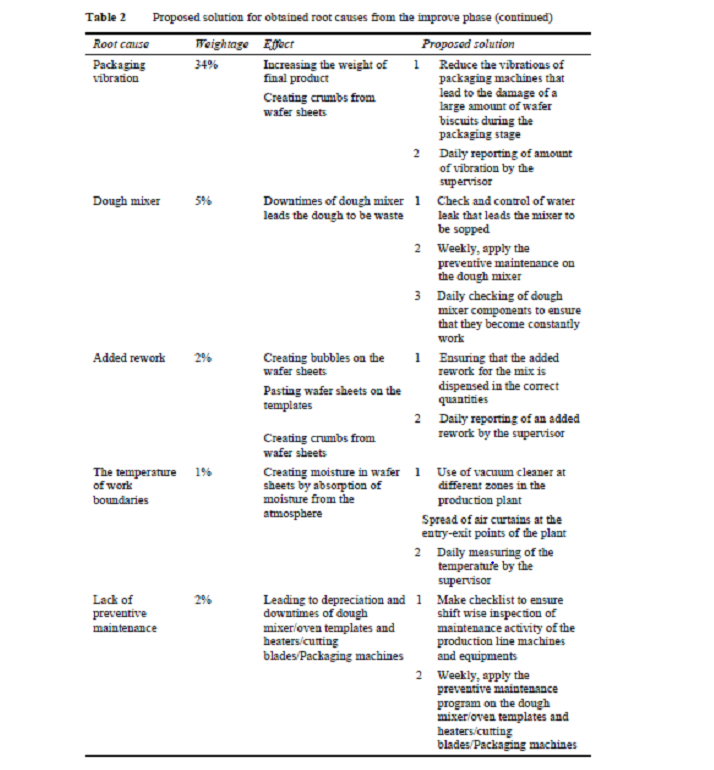

4.4 Improve phase

To reduce flour losses due to the obtained causes, several solutions are suggested. These solutions are considered for each root cause. Moreover, the solutions are constructed in collaboration with the improvement team members. Table 2 illustrates the obtained root causes, weightage of causes, effects of causes and suggested solutions. Where weightage of each root cause was obtained by analyzing the monthly reports of production department for the past 20 months.

4.5 Control phase

The goal of the control phase is to maintain the gains from the suggested solutions and prevent the repetition of defects. Nevertheless, due to time limitation, this phase is still under improvement at the wafer biscuit production in Y Company. To get long-lasting effects, periodical observation of the process is required to detect the changes and keep it under control. Moreover, the process needs to be observed accurately from time to time in order to obtain appropriate results. This will facilitate the observation tasks of the operators and the maintenance crew as they will only need to review the date of previous and next service appeared on the sticker and will inform the maintenance staff to perform the routine maintenance tasks on the machines. In addition,

the machine operators should be trained in quality control and assurance so that if there is any change in the process, they should inform the quality supervisor on time. Proper implementation of these suggestions will help out in eradicating the changes in the process.

Questions

- What kind of problem is Y Company facing? (1 Mark)

- Could you describe the improvement strategy followed in this problem solving ? (1 Mark)

- Describe what is done within each step of the DMAIC strategy ? (2 Mark)

- What are the sources of problem? Root causes? Which tool was used to determine the sources and the root causes of the problem by the team? (3 Mark)

- How do they suggest to remove the cause of the waste? (2 Mark)

- How can we sustain these actions according to you? (1 Mark)

Supplier Input Process Output Customer A Plant Flour Dough Mixer Wafer Biscuit Internal Customer B Plant Suger Deformation C Plant Ghee External Customer 1-0-0-0-0-0 Baking D Plant kako E Plant Cover Cutting F Plant Carton Creaming Packing Figure 3 Flour usage per month Flour usage per month 450 400 350 300 Quantity (Ton) 250 200 150 100 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Actual per month 267275320247229367 279270398 239 339 406 423 351 402 348 324 321 212431 Required per month 234224275200 182 288200 192 250 190 301 310 332285335 280 253235 173331 Table 1 Flour loss areas and types of defects Flour loss Total loss quantity areas (ton per month) Type of defects Ovens 31.61 65% Pasting on the templates 22% High bubbles 13% Low temperature and colour Packaging 24.50 56% High humidity machines 35% Increasing weights 9% Crumbs through the packaging Cutting 8.86 Crumbs through the cutting machines Dough mixers 3.70 Dough loss downtime Other 0.26 Other causes Total 68.93 Loss quantity (Ton per month) 20.55 6.95 4.11 13.72 8.58 2.21 8.86 3.70 0.26 68.93 Environment Machine Management High-temperature Oven templates Dough mixer Monitoring downtimes -Humidity Oven heater Policy Cutting blades Untidy workplace *Packaging vibration Incentive Cutting speed Flour loss Preventive maintenance lack of training Added rework -Effectiveness lack of experience Flour Spare parts lack of responsibility Maintenance Man Material Table 2 Proposed solution for obtained root causes from the improve phase Root cause Weightage Effect Proposed solution Oven templates 43% Pasting wafer sheets on the i Check the thermostat and heaters templates sensors at the zones of oven Burning the edges of wafer 2 Adjust the speed of the sheets conveyor belt according to temperature of the oven Creating moisture in wafer 3 Unify the brand of used sheets flour material to investigate the quality of flour Creating bubbles on the 4 Adjust the baking time over wafer sheets a range of 1.5-2.5 min to guarantee capability to bake to even moisture, thickness, texture and colour 5 Eliminate and clean the remains dough on the templates by special brush 6 Frequently, clean the remnant crumb from flame nozzles and tubes inside the ovens to make sure the temperature is distributed properly 7 Maintain the continuous flame that impinges onto the plates as a stable and uniform height 8 The residual moisture inside oven would expect to be within the range of 1-2% 9 The residual moisture is not to vary from sheet to sheet by more than +/-0.25% 10 Daily reporting of amount of moisture inside oven by the supervisor 5% Table 2 Proposed solution for obtained root causes from the improve phase (continued) Root cause Teightage Efect Proposed solution Packaging 34% Increasing the weight of 1 Reduce the vibrations of vibration final product packaging machines that Creating crumbs from lead to the damage of a wafer sheets large amount of wafer biscuits during the packaging stage 2 Daily reporting of amount of vibration by the supervisor Dough mixer Downtimes of dough mixer 1 Check and control of water leads the dough to be waste leak that leads the mixer to be sopped 2 Weekly, apply the preventive maintenance on the dough mixer 3 Daily checking of dough mixer components to ensure that they become constantly work Added rework 2% Creating bubbles on the 1 Ensuring that the added wafer sheets rework for the mix is Pasting wafer sheets on the dispensed in the correct templates quantities 2 Daily reporting of an added Creating crumbs from rework by the supervisor wafer sheets The temperature 1% Creating moisture in wafer 1 Use of vacuum cleaner at of work sheets by absorption of different zones in the boundaries moisture from the production plant atmosphere Spread of air curtains at the entry-exit points of the plant 2 Daily measuring of the temperature by the supervisor Lack of 2% Leading to depreciation and 1 Make checklist to ensure preventive downtimes of dough shift wise inspection of maintenance mixeroven templates and maintenance activity of the heaters/cutting production line machines blades/Packaging machines and equipments 2 Weekly, apply the preventive maintenance program on the dough mixeroven templates and heaters/cutting blades/Packaging machines

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts