Question: CASE STUDY 9 - THE GRIL-KLEEN CORPORATION. PLEASE DO A CASE ANALYSIS FOR CASE STUDY 9 - THE GRIL-KLEEN CORPORATION I. Introduction / Executive Summary

CASE STUDY 9 - THE GRIL-KLEEN CORPORATION.

PLEASE DO A CASE ANALYSIS FOR CASE STUDY 9 - THE GRIL-KLEEN CORPORATION

I. Introduction / Executive Summary II. Background Information III. Case Evaluation IV. Alternative Solutions V. Main Answer VI. Recommendations

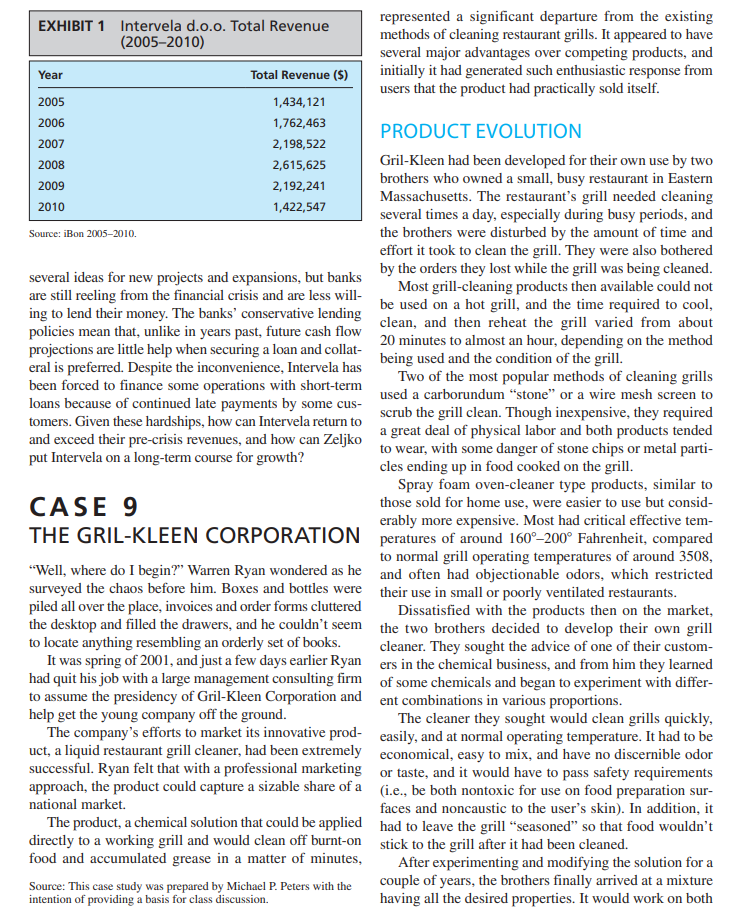

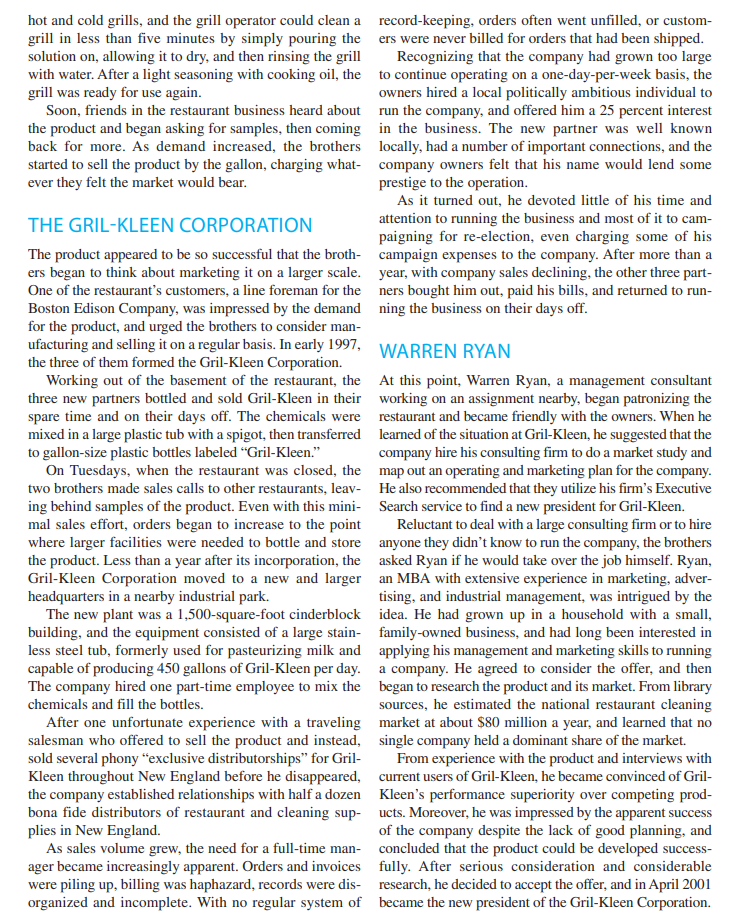

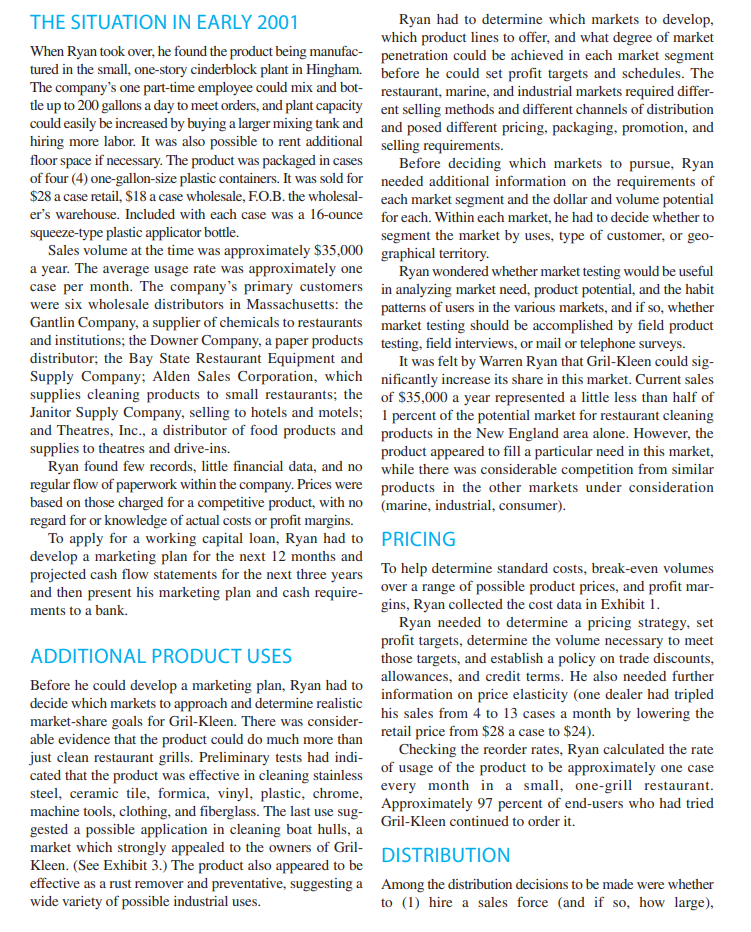

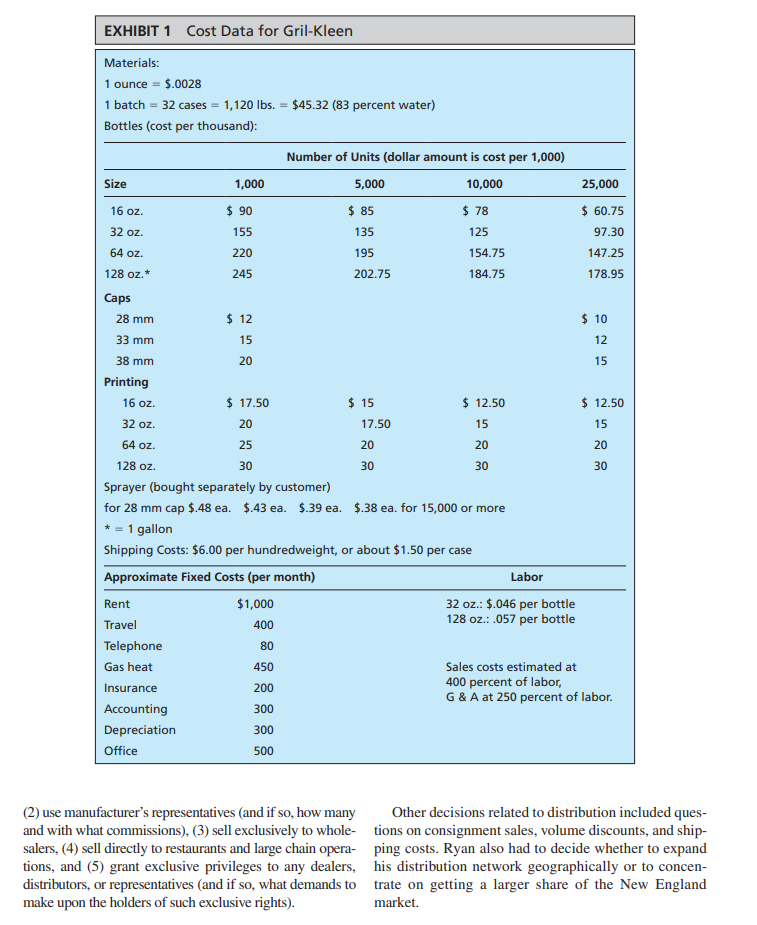

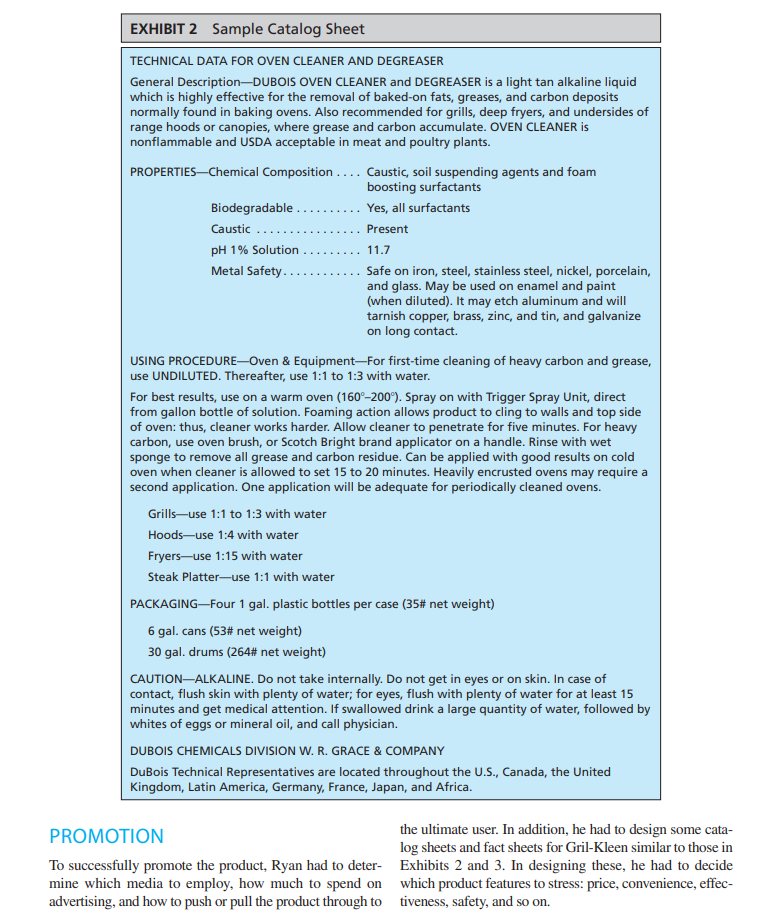

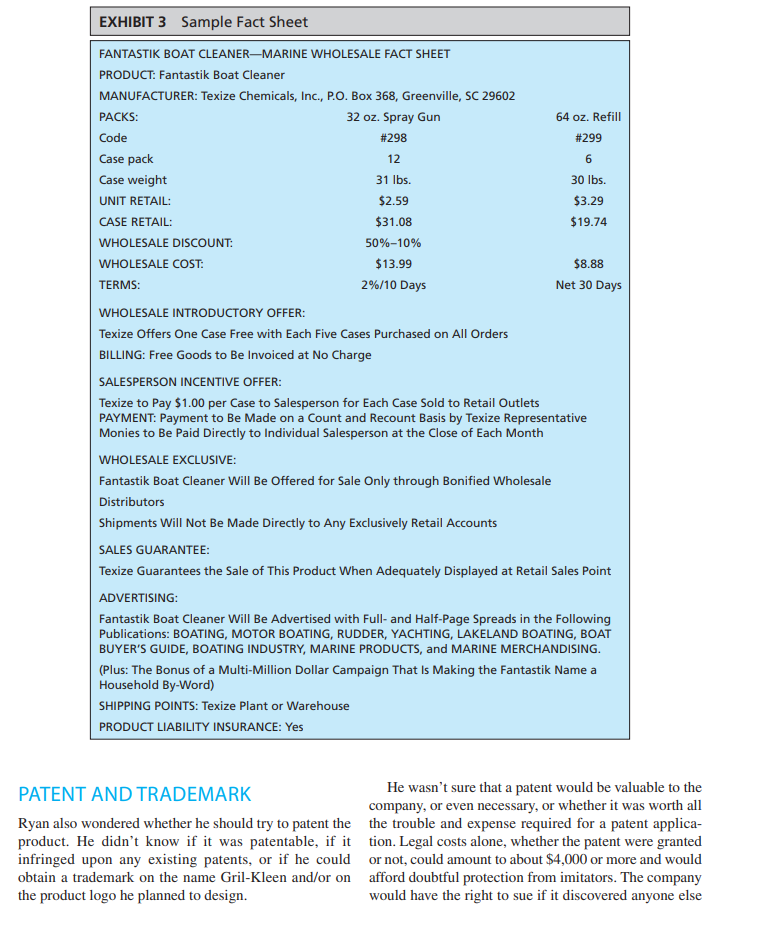

2005 2010 represented a significant departure from the existing EXHIBIT 1 Intervela d.o.o. Total Revenue (2005-2010) methods of cleaning restaurant grills. It appeared to have several major advantages over competing products, and Year Total Revenue ($) initially it had generated such enthusiastic response from users that the product had practically sold itself. 1,434, 121 2006 1,762,463 PRODUCT EVOLUTION 2007 2,198,522 2008 2,615,625 Gril-Kleen had been developed for their own use by two 2009 2,192,241 brothers who owned a small, busy restaurant in Eastern Massachusetts. The restaurant's grill needed cleaning 1,422,547 several times a day, especially during busy periods, and Source: iBon 2005-2010 the brothers were disturbed by the amount of time and effort it took to clean the grill. They were also bothered several ideas for new projects and expansions, but banks by the orders they lost while the grill was being cleaned. are still reeling from the financial crisis and are less will be used on a hot grill , and the time required to cool, Most grill-cleaning products then available could not ing to lend their money. The banks' conservative lending clean, and then reheat the grill varied from about policies mean that, unlike in years past, future cash flow projections are little help when securing a loan and collat- 20 minutes to almost an hour, depending on the method eral is preferred. Despite the inconvenience, Intervela has being used and the condition of the grill . been forced to finance some operations with short-term used a carborundum "stone or a wire mesh screen to Two of the most popular methods of cleaning grills loans because of continued late payments by some cus- scrub the grill clean. Though inexpensive, they required tomers. Given these hardships, how can Intervela return to a great deal of physical labor and both products tended and exceed their pre-crisis revenues, and how can Zeljko to wear, with some danger of stone chips or metal parti- put Intervela on a long-term course for growth? cles ending up in food cooked on the grill. Spray foam oven-cleaner type products, similar to CASE 9 those sold for home use, were easier to use but consid- erably more expensive. Most had critical effective tem- THE GRIL-KLEEN CORPORATION peratures of around 160-200 Fahrenheit, compared to normal grill operating temperatures of around 3508, Well, where do I begin?" Warren Ryan wondered as he and often had objectionable odors, which restricted surveyed the chaos before him. Boxes and bottles were their use in small or poorly ventilated restaurants. piled all over the place, invoices and order forms cluttered Dissatisfied with the products then on the market, the desktop and filled the drawers, and he couldn't seem the two brothers decided to develop their own grill to locate anything resembling an orderly set of books. cleaner. They sought the advice of one of their custom- It was spring of 2001, and just a few days earlier Ryan ers in the chemical business, and from him they learned had quit his job with a large management consulting firm of some chemicals and began to experiment with differ- to assume the presidency of Gril-Kleen Corporation and ent combinations in various proportions. help get the young company off the ground. The cleaner they sought would clean grills quickly, The company's efforts to market its innovative prod- easily, and at normal operating temperature. It had to be uct, a liquid restaurant grill cleaner, had been extremely economical, easy to mix, and have no discernible odor successful. Ryan felt that with a professional marketing or taste, and it would have to pass safety requirements approach, the product could capture a sizable share of a (i.e., be both nontoxic for use on food preparation sur- national market. faces and noncaustic to the user's skin). In addition, it The product, a chemical solution that could be applied had to leave the grill seasoned" so that food wouldn't directly to a working grill and would clean off burnt-on stick to the grill after it had been cleaned. food and accumulated grease in a matter of minutes, After experimenting and modifying the solution for a Source: This case study was prepared by Michael P. Peters with the couple of years, the brothers finally arrived at a mixture intention of providing a basis for class discussion. having all the desired properties. It would work on both hot and cold grills, and the grill operator could clean a record-keeping, orders often went unfilled, or custom- grill in less than five minutes by simply pouring the ers were never billed for orders that had been shipped. solution on, allowing it to dry, and then rinsing the grill Recognizing that the company had grown too large with water. After a light seasoning with cooking oil, the to continue operating on a one-day-per-week basis, the grill was ready for use again. owners hired a local politically ambitious individual to Soon, friends in the restaurant business heard about run the company, and offered him a 25 percent interest the product and began asking for samples, then coming in the business. The new partner was well known back for more. As demand increased, the brothers locally, had a number of important connections, and the started to sell the product by the gallon, charging what- company owners felt that his name would lend some ever they felt the market would bear. prestige to the operation. As it turned out, he devoted little of his time and THE GRIL-KLEEN CORPORATION attention to running the business and most of it to cam- paigning for re-election, even charging some of his The product appeared to be so successful that the broth- campaign expenses to the company. After more than a ers began to think about marketing it on a larger scale. year, with company sales declining, the other three part- One of the restaurant's customers, a line foreman for the ners bought him out, paid his bills, and returned to run- Boston Edison Company, was impressed by the demand ning the business on their days off. for the product, and urged the brothers to consider man- ufacturing and selling it on a regular basis. In early 1997, WARREN RYAN the three of them formed the Gril-Kleen Corporation. Working out of the basement of the restaurant, the At this point, Warren Ryan, a management consultant three new partners bottled and sold Gril-Kleen in their working on an assignment nearby, began patronizing the spare time and on their days off. The chemicals were restaurant and became friendly with the owners. When he mixed in a large plastic tub with a spigot, then transferred learned of the situation at Gril-Kleen, he suggested that the to gallon-size plastic bottles labeled "Gril-Kleen." company hire his consulting firm to do a market study and On Tuesdays, when the restaurant was closed, the map out an operating and marketing plan for the company. two brothers made sales calls to other restaurants, leav- He also recommended that they utilize his firm's Executive ing behind samples of the product. Even with this mini- Search service to find a new president for Gril-Kleen. mal sales effort, orders began to increase to the point Reluctant to deal with a large consulting firm or to hire where larger facilities were needed to bottle and store anyone they didn't know to run the company, the brothers the product. Less than a year after its incorporation, the asked Ryan if he would take over the job himself. Ryan, Gril-Kleen Corporation moved to a new and larger an MBA with extensive experience in marketing, adver- headquarters in a nearby industrial park. tising, and industrial management, was intrigued by the The new plant was a 1,500-square-foot cinderblock idea. He had grown up in a household with a small, building, and the equipment consisted of a large stain- family-owned business, and had long been interested in less steel tub, formerly used for pasteurizing milk and applying his management and marketing skills to running capable of producing 450 gallons of Gril-Kleen per day. a company. He agreed to consider the offer, and then The company hired one part-time employee to mix the began to research the product and its market. From library chemicals and fill the bottles. sources, he estimated the national restaurant cleaning After one unfortunate experience with a traveling market at about $80 million a year, and learned that no salesman who offered to sell the product and instead, single company held a dominant share of the market. sold several phony "exclusive distributorships for Gril- From experience with the product and interviews with Kleen throughout New England before he disappeared, current users of Gril-Kleen, he became convinced of Gril- the company established relationships with half a dozen Kleen's performance superiority over competing prod- bona fide distributors of restaurant and cleaning sup- ucts. Moreover, he was impressed by the apparent success plies in New England. of the company despite the lack of good planning, and As sales volume grew, the need for a full-time man- concluded that the product could be developed success- ager became increasingly apparent. Orders and invoices fully. After serious consideration and considerable were piling up, billing was haphazard, records were dis- research, he decided to accept the offer, and in April 2001 organized and incomplete. With no regular system of became the new president of the Gril-Kleen Corporation. THE SITUATION IN EARLY 2001 Ryan had to determine which markets to develop, which product lines to offer, and what degree of market When Ryan took over, he found the product being manufac- penetration could be achieved in each market segment tured in the small, one-story cinderblock plant in Hingham. before he could set profit targets and schedules. The The company's one part-time employee could mix and bot- restaurant, marine, and industrial markets required differ- tle up to 200 gallons a day to meet orders, and plant capacity ent selling methods and different channels of distribution could easily be increased by buying a larger mixing tank and and posed different pricing, packaging, promotion, and hiring more labor. It was also possible to rent additional selling requirements. floor space if necessary. The product was packaged in cases Before deciding which markets to pursue, Ryan of four (4) one-gallon-size plastic containers. It was sold for needed additional information on the requirements of $28 a case retail, $18 a case wholesale, F.O.B. the wholesal- each market segment and the dollar and volume potential er's warehouse. Included with each case was a 16-ounce for each. Within each market, he had to decide whether to squeeze-type plastic applicator bottle. segment the market by uses, type of customer, or geo- Sales volume at the time was approximately $35,000 graphical territory. a year. The average usage rate was approximately one Ryan wondered whether market testing would be useful case per month. The company's primary customers in analyzing market need, product potential, and the habit were six wholesale distributors in Massachusetts: the patterns of users in the various markets, and if so, whether Gantlin Company, a supplier of chemicals to restaurants market testing should be accomplished by field product and institutions; the Downer Company, a paper products testing, field interviews, or mail or telephone surveys. distributor; the Bay State Restaurant Equipment and It was felt by Warren Ryan that Gril-Kleen could sig- Supply Company; Alden Sales Corporation, which nificantly increase its share in this market. Current sales supplies cleaning products to small restaurants; the of $35,000 a year represented a little less than half of Janitor Supply Company, selling to hotels and motels; 1 percent of the potential market for restaurant cleaning and Theatres, Inc., a distributor of food products and products in the New England area alone. However, the supplies to theatres and drive-ins. product appeared to fill a particular need in this market, Ryan found few records, little financial data, and no while there was considerable competition from similar regular flow of paperwork within the company. Prices were products in the other markets under consideration based on those charged for a competitive product, with no (marine, industrial, consumer). regard for or knowledge of actual costs or profit margins. To apply for a working capital loan, Ryan had to PRICING develop a marketing plan for the next 12 months and projected cash flow statements for the next three years To help determine standard costs, break-even volumes and then present his marketing plan and cash require- over a range of possible product prices, and profit mar- ments to a bank. gins, Ryan collected the cost data in Exhibit 1. Ryan needed to determine a pricing strategy, set profit targets, determine the volume necessary to meet ADDITIONAL PRODUCT USES those targets, and establish a policy on trade discounts, Before he could develop a marketing plan, Ryan had to allowances, and credit terms. He also needed further decide which markets to approach and determine realistic information on price elasticity (one dealer had tripled market-share goals for Gril-Kleen. There was consider- his sales from 4 to 13 cases a month by lowering the able evidence that the product could do much more than retail price from $28 a case to $24). just clean restaurant grills. Preliminary tests had indi- Checking the reorder rates, Ryan calculated the rate cated that the product was effective in cleaning stainless of usage of the product to be approximately one case steel, ceramic tile, formica, vinyl, plastic, chrome, every month in a small, one-grill restaurant. machine tools, clothing, and fiberglass. The last use sug- Approximately 97 percent of end-users who had tried gested a possible application in cleaning boat hulls, a Gril-Kleen continued to order it. market which strongly appealed to the owners of Gril- DISTRIBUTION Kleen. (See Exhibit 3.) The product also appeared to be effective as a rust remover and preventative, suggesting a Among the distribution decisions to be made were whether wide variety of possible industrial uses. to (1) hire a sales force (and if so, how large), 15 EXHIBIT 1 Cost Data for Gril-Kleen Materials: 1 ounce = $.0028 1 batch = 32 cases = 1,120 lbs. = $45.32 (83 percent water) Bottles (cost per thousand): Number of Units (dollar amount is cost per 1,000) Size 1,000 5,000 10,000 25,000 16 oz. $ 90 $ 85 $ 78 $ 60.75 32 oz. 155 135 125 97.30 64 oz. 220 195 154.75 147.25 128 oz.* 245 202.75 184.75 178.95 Caps 28 mm $ 12 $ 10 33 mm 12 38 mm 20 15 Printing 16 oz. $ 17.50 $ 15 $ 12.50 $ 12.50 32 oz. 20 17.50 15 15 64 oz. 25 20 20 20 128 oz. 30 30 30 30 Sprayer (bought separately by customer) for 28 mm cap $.48 ea. $.43 ea. $.39 ea. $.38 ea. for 15,000 or more * = 1 gallon Shipping Costs: $6.00 per hundredweight, or about $1.50 per case Approximate Fixed Costs (per month) Labor Rent $1,000 32 oz.: $.046 per bottle Travel 400 128 oz.:.057 per bottle Telephone 80 Gas heat 450 Sales costs estimated at Insurance 200 400 percent of labor, G&A at 250 percent of labor. Accounting 300 Depreciation 300 Office 500 . (2) use manufacturer's representatives (and if so, how many Other decisions related to distribution included ques- and with what commissions), (3) sell exclusively to whole- tions on consignment sales, volume discounts, and ship- salers, (4) sell directly to restaurants and large chain opera- ping costs. Ryan also had to decide whether to expand tions, and (5) grant exclusive privileges to any dealers, his distribution network geographically or to concen- distributors, or representatives (and if so, what demands to trate on getting a larger share of the New England make upon the holders of such exclusive rights). market. EXHIBIT 2 Sample Catalog Sheet TECHNICAL DATA FOR OVEN CLEANER AND DEGREASER General Description-DUBOIS OVEN CLEANER and DEGREASER is a light tan alkaline liquid which is highly effective for the removal of baked-on fats, greases, and carbon deposits normally found in baking ovens. Also recommended for grills, deep fryers, and undersides of range hoods or canopies, where grease and carbon accumulate. OVEN CLEANER is nonflammable and USDA acceptable in meat and poultry plants. PROPERTIESChemical Composition .... Caustic, soil suspending agents and foam boosting surfactants Biodegradable. Yes, all surfactants Caustic ..... Present pH 1% Solution 11.7 Metal Safety Safe on iron, steel, stainless steel, nickel, porcelain, and glass. May be used on enamel and paint (when diluted). It may etch aluminum and will tarnish copper, brass, zinc, and tin, and galvanize on long contact. USING PROCEDURE-Oven & Equipment-For first-time cleaning of heavy carbon and grease, use UNDILUTED. Thereafter, use 1:1 to 1:3 with water. For best results, use on a warm oven (160-200). Spray on with Trigger Spray Unit, direct from gallon bottle of solution. Foaming action allows product to cling to walls and top side of oven: thus, cleaner works harder. Allow cleaner to penetrate for five minutes. For heavy carbon, use oven brush, or Scotch Bright brand applicator on a handle. Rinse with wet sponge to remove all grease and carbon residue. Can be applied with good results on cold oven when cleaner is allowed to set 15 to 20 minutes. Heavily encrusted ovens may require a second application. One application will be adequate for periodically cleaned ovens. Grills-use 1:1 to 1:3 with water Hoods-use 1:4 with water Fryersuse 1:15 with water Steak Platter-use 1:1 with water PACKAGINGFour 1 gal. plastic bottles per case (35# net weight) 6 gal. cans (53# net weight) 30 gal. drums (264# net weight) CAUTIONALKALINE. Do not take internally. Do not get in eyes or on skin. In case of contact, flush skin with plenty of water; for eyes, flush with plenty of water for at least 15 minutes and get medical attention. If swallowed drink a large quantity of water, followed by whites of eggs or mineral oil, and call physician. DUBOIS CHEMICALS DIVISION W. R. GRACE & COMPANY DuBois Technical Representatives are located throughout the U.S., Canada, the United Kingdom, Latin America, Germany, France, Japan, and Africa. PROMOTION the ultimate user. In addition, he had to design some cata- log sheets and fact sheets for Gril-Kleen similar to those in To successfully promote the product, Ryan had to deter- Exhibits 2 and 3. In designing these, he had to decide mine which media to employ, how much to spend on which product features to stress: price, convenience, effec- advertising, and how to push or pull the product through to tiveness, safety, and so on. 12 EXHIBIT 3 Sample Fact Sheet FANTASTIK BOAT CLEANERMARINE WHOLESALE FACT SHEET PRODUCT: Fantastik Boat Cleaner MANUFACTURER: Texize Chemicals, Inc., P.O. Box 368, Greenville, SC 29602 PACKS: 32 oz. Spray Gun 64 oz. Refill Code #298 #299 Case pack 6 Case weight 31 lbs. 30 lbs. UNIT RETAIL: $2.59 $3.29 CASE RETAIL: $31.08 $19.74 WHOLESALE DISCOUNT 50%-10% WHOLESALE COST: $13.99 $8.88 TERMS: 2%/10 Days Net 30 Days WHOLESALE INTRODUCTORY OFFER: Texize Offers One Case Free with Each Five Cases Purchased on All Orders BILLING: Free Goods to Be Invoiced at No Charge SALESPERSON INCENTIVE OFFER: Texize to pay $1.00 per Case to Salesperson for Each Case Sold to Retail Outlets PAYMENT: Payment to Be Made on a Count and Recount Basis by Texize Representative Monies to Be Paid Directly to Individual Salesperson at the Close of Each Month WHOLESALE EXCLUSIVE: Fantastik Boat Cleaner Will Be Offered for Sale Only through Bonified Wholesale Distributors Shipments Will Not Be Made Directly to Any Exclusively Retail Accounts SALES GUARANTEE: Texize Guarantees the sale of This Product When Adequately Displayed at Retail Sales Point ADVERTISING: Fantastik Boat Cleaner Will Be Advertised with Full- and Half-Page Spreads in the following Publications: BOATING, MOTOR BOATING, RUDDER, YACHTING, LAKELAND BOATING, BOAT BUYER'S GUIDE, BOATING INDUSTRY, MARINE PRODUCTS, and MARINE MERCHANDISING. (Plus: The Bonus of a Multi-Million Dollar Campaign That Is Making the Fantastik Name a Household By-Word) SHIPPING POINTS: Texize Plant or Warehouse PRODUCT LIABILITY INSURANCE: Yes PATENT AND TRADEMARK He wasn't sure that a patent would be valuable to the company, or even necessary, or whether it was worth all Ryan also wondered whether he should try to patent the the trouble and expense required for a patent applica- product. He didn't know if it was patentable, if it tion. Legal costs alone, whether the patent were granted infringed upon any existing patents, or if he could or not, could amount to about $4,000 or more and would obtain a trademark on the name Gril-Kleen and/or on afford doubtful protection from imitators. The company the product logo he planned to design. would have the right to sue if it discovered anyone else using its formula, but patent litigation would be too volume discount schedules and determine the effects time-consuming and expensive for a company of Gril- of any increase or decrease in price on demand and Kleen's size. on profits. They should consider whether any market or product COMPETITION testing is necessary, and if so, what type and how much. These decisions would form the basis for Gril-Kleen's The most common grill cleaning products then in use, marketing plan, from which Warren Ryan could develop especially in smaller restaurants, were the "stone" and projected cash flow statements and estimate his work- the screen. The stone is a block of carborundum (harding capital needs over the next 12 months. soapstone) about the size of a brick, which was used to scrub the grill and remove grease and food residue. The screen was a wire mesh screen placed in a device simi- CASE 10 lar to a sandpaper holder which was used to scour the grill much like home scouring pads. Both were inexpen- MASI TECHNOLOGY sive but required a great deal of effort to use, took about an hour to clean a fairly dirty grill, and could not be U.S. FISH INDUSTRY used on a hot grill . In addition, the stone especially The U.S. fishing industry is a large, highly fragmented tended to wear and chip, with some danger that stone business, characterized by dwindling resources and chips might end up in food cooked on the grill. There were also several chemical liquid and spray equal amounts of finfish" and "shellfish."2 with an extremely poor regulatory oversight. It is composed of foam oven-cleaner-type products on the market that could be used to clean grills. Most of these were fairly aggregate landed" value of approximately $8.5 billion, expensive and had critical effective temperatures of consisting of 19 billion lbs. of product. around 1608 to 2008F. These competitive products were The U.S. industry is composed of a domestic compo- generally marketed by fairly large companies, with nent supplied by the 25,000 U.S. registered vessels large advertising budgets and wide distribution net operating within the 200 mile federal territory known as works. Among these were Swell, DuBois, Easy-off, tions as Mexico, Chile, Equador, South Africa, the the EEZ, and an imported component from such loca- and Jifoam. Colgate-Palmolive and Lever Brothers also had plans to introduce new chemical oven cleaner Phillippines, and Sri Lanka, to mention a few. It is estimated that the domestic business generates products. DuBois liquid oven cleaner (see Exhibit 2) was sold about $4 billion in income and 12 billion lbs. in landed in four-gallon cases for $28.00 a case retail and weight. This amount is estimated to be equally divided employed its own sales force to sell directly to retailers. total comes from within the EEZ. There are also 55,000 between finfish and shellfish. About 98 percent of this Swell was marketed via wholesale distributors for $7.00 registered domestic sports fishing vessels that are esti- a gallon or $26.50 a case retail and used its own sales mated to catch somewhere in the range of 1015 million force to sell to wholesalers. lbs. of fish per year. Because the vast majority of this product does not move through U.S. processing/ distri- DEVELOPING A MARKETING PLAN bution facilities, it is impossible to generate reliable To develop a sound marketing plan, it was necessary to due to severely -over-fished U.S. sites, represents numbers. The imported component, which is growing determine the size of the potential market in units and dollars, estimate the market share that Gril-Kleen could about $4.5 billion in retail value, but only about 7 billion expect to attain, and then develop sales projections over "loined" form. Approximately 20 percent is flown in as in weight because the vast majority is imported in a 12-month period. They needed to find out who and where the distrib- fresh, and 80 percent arrives by boat as flash frozen" utors of restaurant cleaning products in New England or frozen product. None of these figures include were and determine the best means of selling to them. armed product or canned tuna. They also had to calculate potential sales volumes at various prices and price the product to maximize Source: This case study was prepared by Michael P. Peters with the profits (or volume). They would need to construct intention of providing a basis for class discussionStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts