Question: Case Study a2: Delfs Supply Chain Integration Dell, a 57.bilion-dollar industor, emplovs its supply chuin sybtems untike any other PC maker on the planet. The

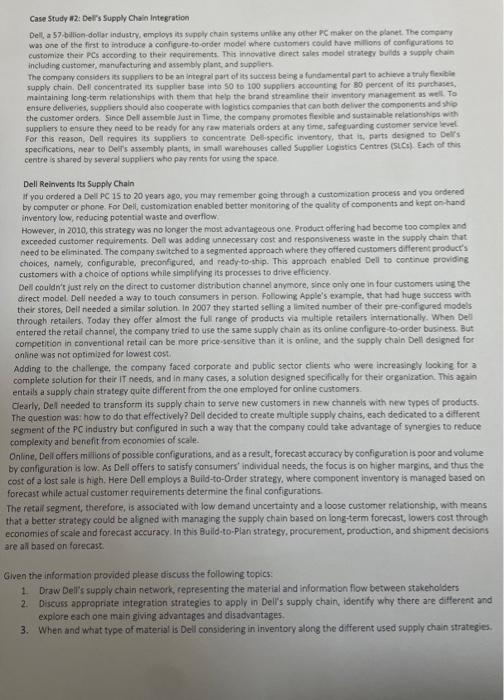

Case Study a2: Delfs Supply Chain Integration Dell, a 57.bilion-dollar industor, emplovs its supply chuin sybtems untike any other PC maker on the planet. The compuny, was one of the first to introduce a configure-to-otdet model where cuntomers could have milions of confinurationd to customize their PCS accotding to their requiremente. This irnovative direct sales model iratecr bulds a supply chair including customer, manufacturing and assembly plant, and supplich. The compony considers its wopllers to be an integral part of its success being a fundamental part to achieve a truly fircibin supply chain. Dell concentrated its supplier tase into 50 to 100 supoliers accountirs for 80 percent of its parchases. maintaining long term relationthipi with them that help the brand streamline their innentory management as well. To ensure deliveries, suppliers should abso cooperate with lapitics companies that can boeh deliver the components and ahio the custamer orders. Since Dell asemble lust in Time, the company promotes flewible and sustainable relationships with supplers to ensure they need to be reidy for any raw materials orders at any time, safcguarding cuttomer service level. for this reason, Dell requires its suppliers so concentrate Delspedfic inventofy, that is, parts designed to Del's specifications, near to Delis assembly plants, in umall warehouses called Supoler togistics Centres (StCs). Each of this centre is shared by several suppliers who pay rents for wine the space Dell Reinvents its Supply Chain If you ordered a Dell PC 15 to 20 years dgo, you may remiember going through a customitation procers and you ordereg, by computer or phone. For Dell, customiation enabled better monitoring of the quality of components and kept on:hand inventory low, reducing potential waste and overflow However, in 2010 , this strategy was no longer the most advantageous one. Product offering had becorne too complex and exceoded customer requirements. Dell was adding unnecessary cost and responsiveness waste in the supply chain that need to be eiminated. The company switched to a segmented approach where they oftered customers different product's choices, namely, configurable. preconfigured, and ready-to-ship. This approach enabled Dell to continue providing customers with a choice of options while simplifying its processes to dive efficiensy. Dell couldn't just rely on the direct to customer distribution channel anymore, since only one in four customens usire the direct model. Dell needed a way to touch consumers in person. Following Apple's example, that had huge success with their stores, Dell needed a similar solution. In 2007 they started selling a limited number of their pre-configured models through retallers. Yoday they offer almost the full range of products via multiple retailers internationally. When Del. entered she retail channel, the company tried to use the same supply chain as its online configure-to-order business. But competition in conventional retail can be more price -sensitwe than it is online, and the supply chain Dell designed for online was not optimized for lowest cost Adding to the challenge, the company faced corporate and public sector clients who were increasingly lockirg for a complete solution for their it needs, and in many cases, a solution designed specifically for their organization. This again entails a supply chain strategy quite different from the one employed for online customers Clearly, Del needed to transform its supply chain to serve new customers in new channels with new types of products. The question was: how to do that effectively? Dell decided to create multiple supply chains, each dedicated to a dififerent segment of the PC industry but configured in such a way that the company could take advantage of synergies to reduce complexity and benefit from economies of scale. Online, Dell offers mitions of possible configurations, and as a result, forecast accuracy by configuration is poor and volume by configuration is low. As Dell offers to satisfy consumers' individual needs, the focus is on higher margins, and thus the cost of a last sale is high. Here Dell employs a Build-to-Order strategy, Where component inventory is managed based on forecast while actual customer requirements determine the final configurations The retail segment, therefore, is associated with low demand uncertainty and a loose customer relationship, with means that a better strategy could be aligned with managing the supply chain based on iong-term forecast, lowers cost through economies of seale and forecast accuracy. In this Build-to-Plan strategy, grocurement; production, and shipment decisions are all based on forecast. Given the information provided please discuss the following topics: 1. Draw Dells supply chain network, representing the material and information flow between stakeholders 2. Discuss appropriate integration strategies to apply in Dell's supply chain, identify why there are ditterent and explore each one main giving advantages and disadvantages 3. When and what type of material is Dell considering in inventory along the different used supply chain atrategies

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts