Question: Case study (above) Description - The current process (above in the case study) )does not work efficiently, and management is considering improving the process by

Case study (above)

Description

- The current process (above in the case study) )does not work efficiently, and management is considering improving the process by using technology and best practice redesign. The purpose of these writings is to improve the process in a way that addresses the issues.

---- Questions below are based on Business Process Management(BPM) ----

1. Problem analysis

- Identify key problems/issues faced by the business and the process using the best practices, methodologies, and technologies/BPMS. Please keep in mind that technology and automation cannot solve all problems; sometimes, the best practices can also improve the efficiency of the processes. To make sure that management agrees with your decisions, you need to explain why your solutions can solve the problems. You have to be realistic and need to consider business capabilities when you provide suggestions and solutions

2. Recommendation - A summary is providing a holistic picture of how you have approached the problems or opportunities and of how the All You Need Office Supplies Ltd. Order Handling Process will be improved if your recommendations are implemented.

3. Key benefits

- Discussed and found from both problem analysis and recommendations.

4. Use of automation - Discuss if automation is a future solution, why or why not.

5. Assumptions and limitations.

6. A change management plan (how you manage changes).

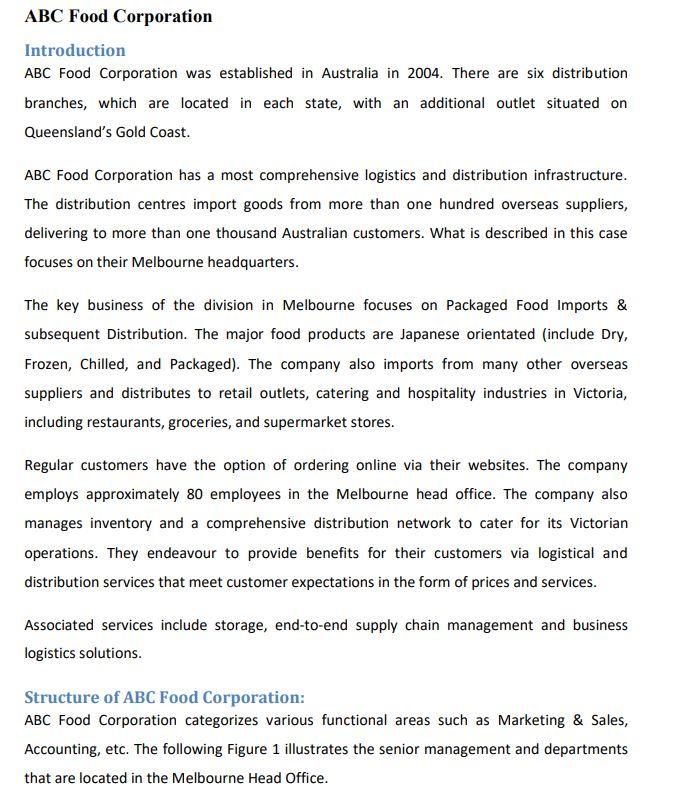

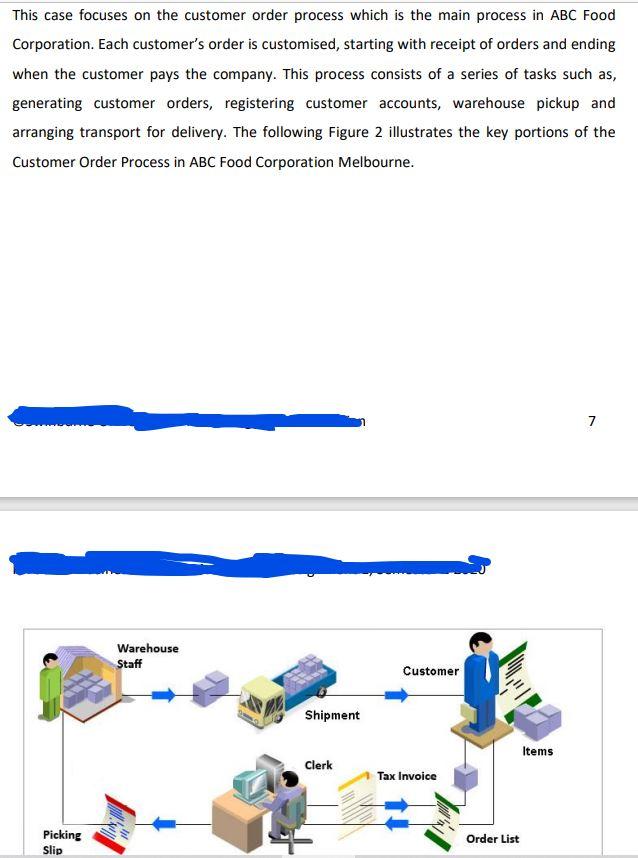

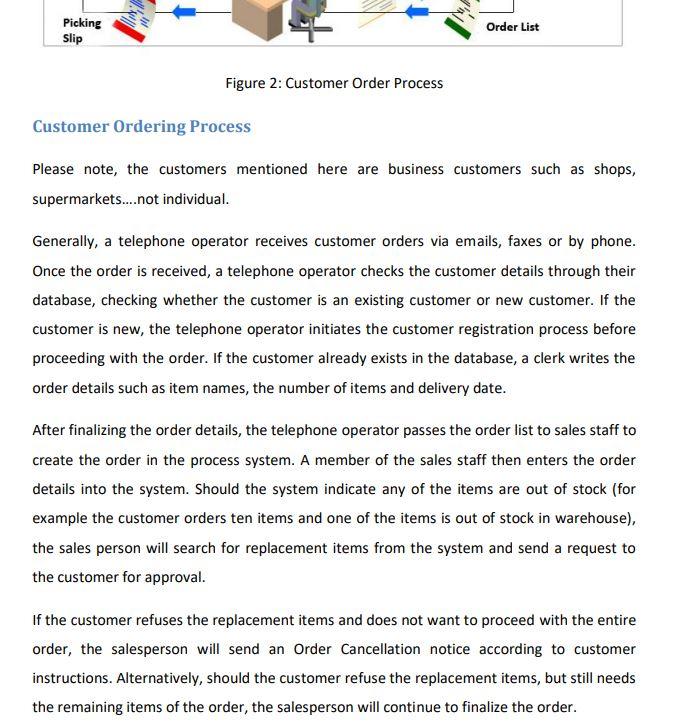

ABC Food Corporation Introduction ABC Food Corporation was established in Australia in 2004. There are six distribution branches, which are located in each state, with an additional outlet situated on Queensland's Gold Coast. ABC Food Corporation has a most comprehensive logistics and distribution infrastructure. The distribution centres import goods from more than one hundred overseas suppliers, delivering to more than one thousand Australian customers. What is described in this case focuses on their Melbourne headquarters. The key business of the division in Melbourne focuses on Packaged Food Imports & subsequent Distribution. The major food products are Japanese orientated (include Dry, Frozen, Chilled, and Packaged). The company also imports from many other overseas suppliers and distributes to retail outlets, catering and hospitality industries in Victoria, including restaurants, groceries, and supermarket stores. Regular customers have the option of ordering online via their websites. The company employs approximately 80 employees in the Melbourne head office. The company also manages inventory and a comprehensive distribution network to cater for its Victorian operations. They endeavour to provide benefits for their customers via logistical and distribution services that meet customer expectations in the form of prices and services. Associated services include storage, end-to-end supply chain management and business logistics solutions. Structure of ABC Food Corporation: ABC Food Corporation categorizes various functional areas such as Marketing & Sales, Accounting, etc. The following Figure 1 illustrates the senior management and departments that are located in the Melbourne Head Office. Managing Director Finance & Administration Director Executive Director General Manager Import & Procurement Manager National Sales Manager Daiwa Food (VIC) Accounts Department Administrator Sales/ Marketing Ichiba Website Team Telephone Operators Team Logistic Department Warehouse Department Team Figure 1: Organizational Chart Organizational Culture According to the ABC Food Corporation's structure, the different departments occasionally have employees overlapping where one department's work is directly related to other departments. This business is structured and there are clear levels of responsibility. Management of the Melbourne branch is expected to follow senior management instructions, document all decisions and send monthly reports to senior management. All recommendations have to be clearly explained and supported by detailed data. Mid-level managers are expected to follow rules and guidelines. In situations that might incur risk or involve deviation from standard practice, they are required to report to senior management before proceeding. There are exhaustive rules and regulations that lower level employees are required to follow and managers supervise these employees closely. Work activities are individually designed, but they encourage certain levels of collaboration. The company follows four major criteria for staff hiring and culture in their organization as follows: . They hire people who are considered compatible to their culture and organization. They want people with knowledge and experience in the food industry. They want people who are active participants and have confidence with decisions within their problem scope. They believe that collaboration can bring creative ideas. Most importantly, they want team orientated people rather than individuals because they believe a good team produces sustainable productivity. ABC Food Corporation also organize special events, such as New Year, Christmas, Easter and Australia Day parties where all employees of ABC Food Corporation are invited to participate in leisure type activities, and are encouraged to liaise with management. These events are designed to relieve work stress and pressures. Existing Strategies and business Process Alignment ABC Food Corporation's main strategy is to provide third party services to sustain customer- supplier relationships. It is the major Japanese food importer & distributor in Australia. Company philosophy is to supply quality and healthy foods to customers, bringing a unique and true experience of Japanese cuisine. This case focuses on the customer order process which is the main process in ABC Food Corporation. Each customer's order is customised, starting with receipt of orders and ending when the customer pays the company. This process consists of a series of tasks such as, generating customer orders, registering customer accounts, warehouse pickup and arranging transport for delivery. The following Figure 2 illustrates the key portions of the Customer Order Process in ABC Food Corporation Melbourne. 7 Warehouse Staff Customer Shipment Items Clerk Tax Invoice Picking Slip Order List Picking Slip Order List Figure 2: Customer Order Process Customer Ordering Process Please note, the customers mentioned here are business customers such as shops, supermarkets....not individual. Generally, a telephone operator receives customer orders via emails, faxes or by phone. Once the order is received, a telephone operator checks the customer details through their database, checking whether the customer is an existing customer or new customer. If the customer is new, the telephone operator initiates the customer registration process before proceeding with the order. If the customer already exists in the database, a clerk writes the order details such as item names, the number of items and delivery date. After finalizing the order details, the telephone operator passes the order list to sales staff to create the order in the process system. A member of the sales staff then enters the order details into the system. Should the system indicate any of the items are out of stock (for example the customer orders ten items and one of the items is out of stock in warehouse), the sales person will search for replacement items from the system and send a request to the customer for approval. If the customer refuses the replacement items and does not want to proceed with the entire order, the salesperson will send an Order Cancellation notice according to customer instructions. Alternatively, should the customer refuse the replacement items, but still needs the remaining items of the order, the salesperson will continue to finalize the order. If a customer wishes to put currently not available items on the back list, the sales person will check the system, and advise the estimated date when the items can be available. As all their products are from overseas, mostly from Japan, it is hard to have exact date. If the customer is happy to wait, then the sales person will add the back order list into customer order files. When the items become available, the sales person will inform the customer and arrange the shipments. If the customer approves the replacement items, the salesperson will finalize the order by entering the customer name, order date, delivery date, item names and the number of items. The salesperson then proceeds to print the picking slip and the delivery docket and passes them to the warehouse department with the labels to arrange the order. Following the warehouse staff picking the order, sales staff book the transportation for delivery. After the Transport Company delivers the goods, sales staff process the order within the system by updating the order status after which the system will generate an invoice. The invoice is then emailed to the customer. It doesn't matter if the customer has back orders or not, all processes order payments will be deducted from the customer's account. If the back orders take too long and customer wants to cancel, then they have to go through cancel order process and money can be refunded to the customer's account when the process is completed. Customer Account Registration In cases where a new customer wants to make an order, the telephone operator requests customer details such as, company name, contact details and designation, address, etc. After completing the details, telephone operator enters the information into the system to create a customer account. The Accounts department assesses a credit limit and updates other account details (such as selling cost, discounts.). After the registration process is completed, the telephone operator will send a confirmation letter to the customer. Before the customer starts to order, they have to deposit covering money into their account. Arrange picking up orders from the Warehouse After the Quality Controller at the warehouse receives the picking slip and labels, he will assign a warehouse member to pick up the goods. After the pick is completed, the Quality 9 Controller rechecks the items in the order. Should he identify incorrect or damaged items, it will be replaced. The warehouse staff then pack the cartons and paste the labels on them. Finally, warehouse staff measure the cartons (length, width, height and weight of the cartons) and place them into the collection area for the Transport Company to pick up. Transport arrangement After completing the warehouse pick, a salesperson books the transport for delivery to the customer. The salesperson then sends a booking request by email with specific details such as collection address, delivery date and address, contact person's name and phone number at the delivery location & carton measurements. He then awaits the reply confirming booking from the Transport Company. After the Transport Company picks up the order with the delivery docket from the warehouse, they will deliver it to the customer on the due date. The Transport Company will then inform sale staff that delivery has been completed. When the sale staff receive the confirmation, they will update the customer's file and inform the accounts department of the completion, enabling the Accounts Department staff to record delivery information. Transport companies are normally paid monthly. At the end of the month, when the transport companies invoices are received by account department staff, they will match with their information. If all correct, they will pay the invoice. If not, they have to check with the sales staff and transport companies. Occasionally, they may even have to check with customer. Issues in the Current (As-is) Process In the current situation, there are three issues involving the main order process: wrong orders, changed orders, and orders over the credit limit. 1. Wrong Customer Order The first problem is identified in the order process. When a customer wants to order, they should order via email, fax or through phone. When by phone, occasionally the information is misinterpreted and telephone operator writes wrong product names on the list and passes the order to sales staff to create the order in the system. After sales staff and warehouse staff fulfil the order process, the Transport Company will pick up and deliver that order to the customer. Once the order has been delivered, 10 the customer finds that the wrong order has been delivered and he complains to the company. When the telephone operator receives the complaint from the customer, he/she will apologize and take quick action to rectify the error and resend the correct item to customer. The telephone operator again passes that corrected item to sales staff to arrange delivery to customer. When the sales staff receive the corrected item, they will issue a credit note for the wrong item that was delivered originally and send it to the customer. Later a new sales order will be created for the corrected item and arrangements made to deliver it within a specific timeframe. All this causes customer dissatisfaction due to the miscommunication. Making a simple mistake causes extra work throughout the entire process. The Accounting department also suffers from by having to recreate the right invoice to the customer. 2. Customer changing the order A few days after a customer provides the order list to telephone operators, the customer may request an amendment to one of the items in the order list. If the customer requests a change to one of the items in the list after the order has been picked up by the Transport Company, this may result in a loss to the company because the company has to bring back goods from the customer and has to re- arrange delivery on same delivery date as the customer requested. As a result of that the company has to pay the Transport Company for both deliveries. 3. Over credit limit The company has agreements with the customers who need to purchase the goods on terms. Initially, they will give limited credit of $1000 enabling customers to order products from the company within that amount. Payment is required within 14 days. After customers place an order, the amount of credit will be reduced by the dollar amount of goods purchased. The company sends the goods on the specific date with the delivery docket. After delivery, a clerk attaches the invoice and sends an email to customer by informing payment due is within 2 weeks of delivery. If, during these 2 weeks, the customer wants to order again, the current system is not able to check customer credit. Therefore, the system is still available for customer to place an order without checking amount of credit left in the order process until the Accounting department receives a copy of the invoice from the sales department, collect the payment and check the credit limit. 4. Transport company payment process is also time consuming. Sometimes it takes some time to confirm the job completion. Also, when customers received goods, there can be damage. Where this happens, complaints will go to ABC company. The company is then required to replace the goods or provide a refundStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts