Question: Case Study II . A production system specializes in sheet metal fabrication . A wide variety of parts are fabricated for assembly . One simple

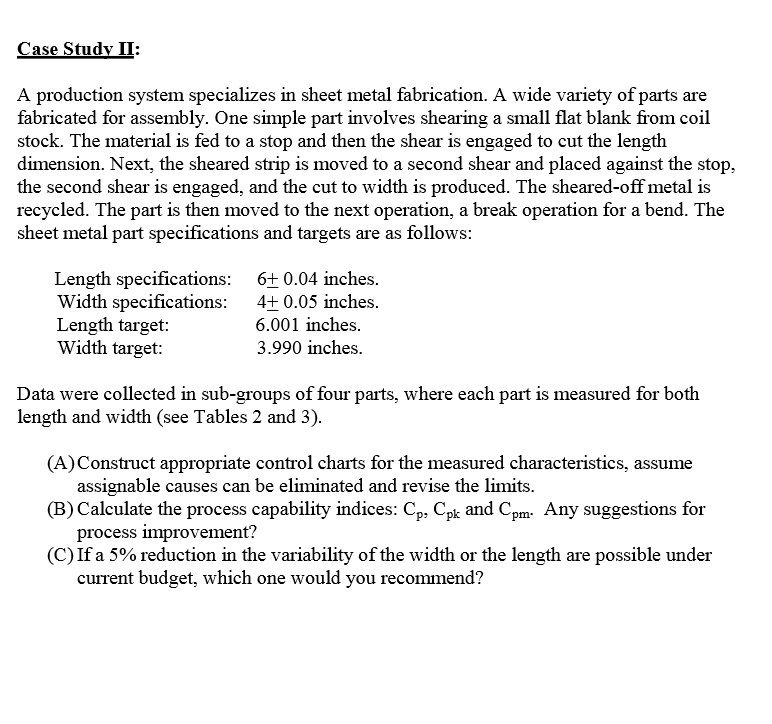

Case Study II . A production system specializes in sheet metal fabrication . A wide variety of parts are fabricated for assembly . One simple part involves shearing a small flat blank from coil stock . The material is fed to a stop and then the shear is engaged to cut the length dimension . Next , the sheared strip is moved to a second shear and placed against the stop . the second shear is engaged , and the cut to width is produced . The sheared - off metal is recycled . The part is then moved to the next operation , a break operation for a bend . The sheet metal part specifications and targets are as follows :" Length specifications :* 6+ 0. 04 inches Width specifications* 4 + 0. 05 inches Length target ." 5. 001 inches . Width target* 3.990 inches . Data were collected in sub- groups of four parts , where each part is measured for both length and width ( see Tables 2 and 3 ) . ( A ) Construct appropriate control charts for the measured characteristics , assume* assignable causes can be eliminated and revise the limits . ( B ) Calculate the process capability indices : Co . Cor and Com. Any suggestions for process improvement ?" ( C ) If a 5% reduction in the variability of the width of the length are possible under* current budget , which one would you recommend ?"

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts