Question: Case Study on ICT in Operations Management Once a COVID-19 vaccine is discovered, the hard part begins BY BEN HUBBARD Vaccines in cold storage at

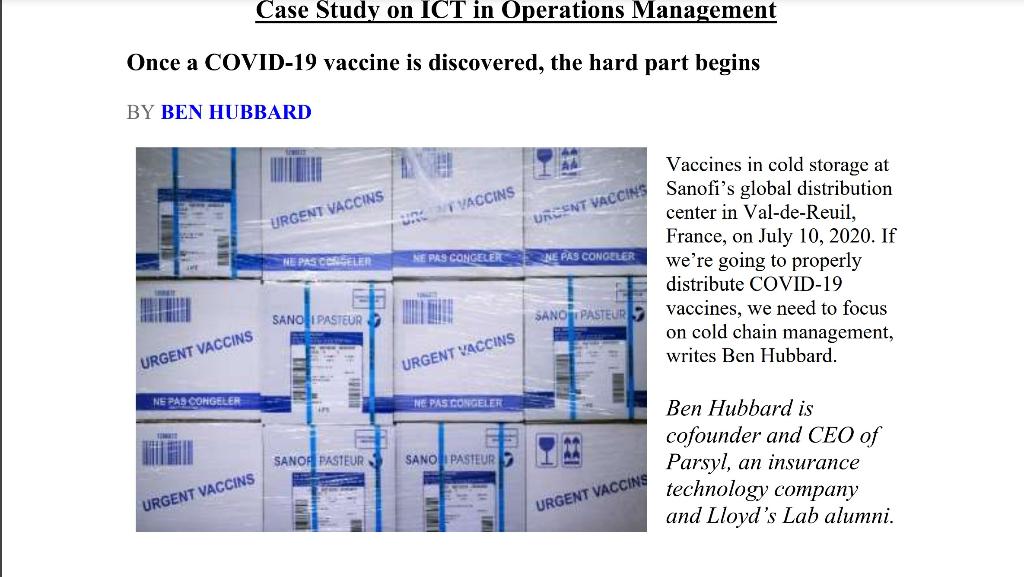

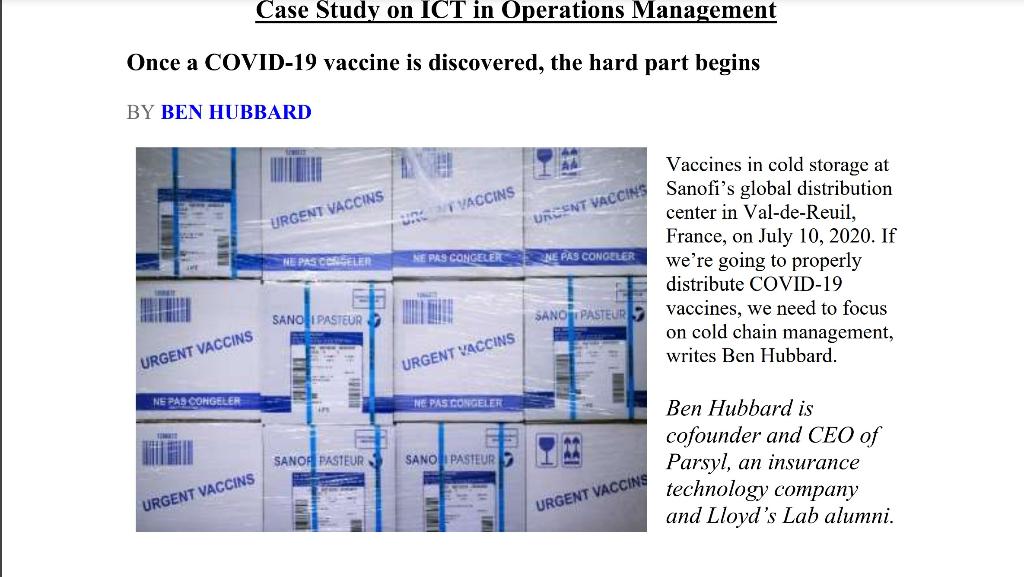

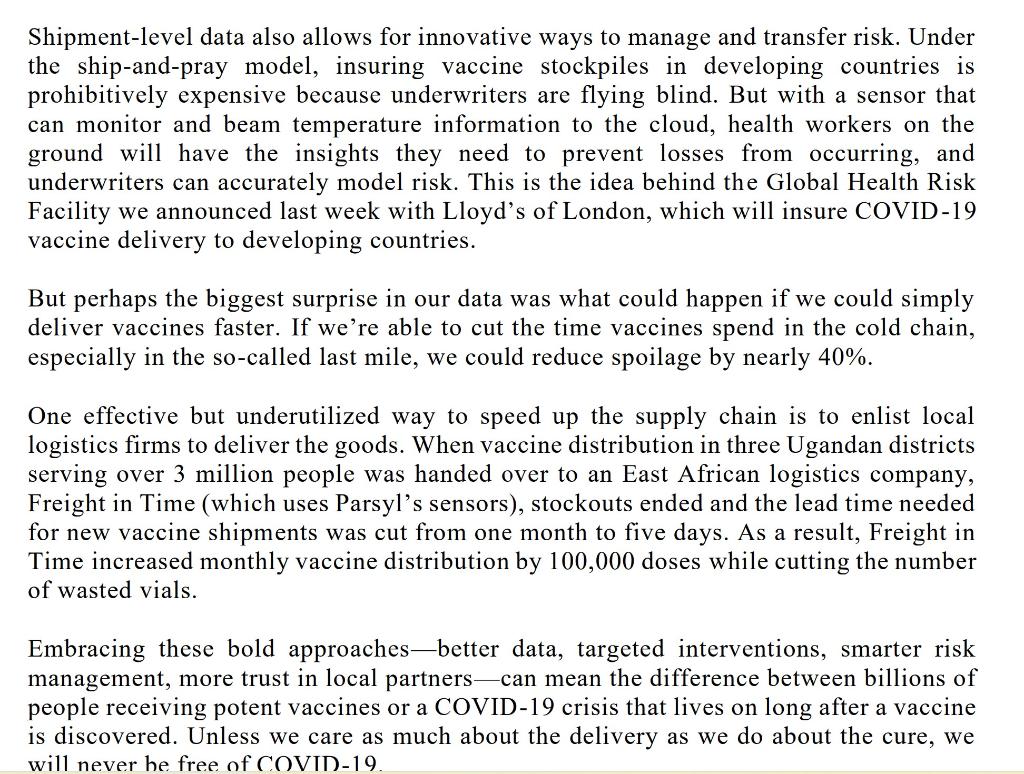

Case Study on ICT in Operations Management Once a COVID-19 vaccine is discovered, the hard part begins BY BEN HUBBARD Vaccines in cold storage at WF VACCINS URSENT VACCINS Sanofi's global distribution URGENT VACCINS NE PAS CESSELER NE PAS CONGELER NE PAS CONGELER center in Val-de-Reuil, France, on July 10, 2020. If we're going to properly distribute COVID-19 vaccines, we need to focus on cold chain management, writes Ben Hubbard. SANO I PASTEUR SANO PASTEUR URGENT VACCINS URGENT VACCINS NE PAS CONGELER NE PAS CONGELER SANOFI PASTEUR SANO PASIEUR Ben Hubbard is cofounder and CEO of Parsyl, an insurance technology company and Lloyd's Lab alumni. URGENT VACCINS URGENT VACCINS In the global sprint to find a COVID-19 vaccine, we've seen the world embrace approaches that would have previously been considered unthinkable, from spending billions on untested technologies to compressing clinical trials from years to months. These bold steps may be exactly what the world needs to find a vaccine even one day sooner. But unless we bring the same kind of urgency, inventiveness, and investment to vaccine distribution as we have to vaccine development, our attempts to end the COVID-19 pandemic will fail. Why does delivering the one thing everyone in the world needs merit such an audacious approach? Because vaccines are delicate things; they require near-perfection in our ability to deliver them. The COVID-19 vaccine, like most vaccines, will need to be kept cold, fixed within a precise temperature range from the moment it leaves the manufacturer to the moment it's administered. This is hard even in rich countries with strong supply chains. In countries with underdeveloped infrastructure, a vaccine's journey can be perilous. If there's any break in the cold chain as a vaccine moves across thousands of miles and changes dozens of hands on its way to a hospital in Dakar, Senegal, a rural health facility in Bihar, India, or a remote clinic in the eastern Democratic Republic of the Congo, it's all for naught; the vaccine will lose its potency. Where you're born shouldn't determine whether you get a vaccine, but if we stay on our current course, it may determine whether it works. Breaks in the cold chain aren't a new problem, but they've mostly been ignored. Over the past two decades, wealthy governments and pharmaceutical companies have laudably partnered to make vaccines available at lower prices for developing countries. But once these precious commodities reach the port of entry, attention to them often fades. There's a cynical term of art for this approach: ship and pray. In God we trust, the saying goes, all others must bring data. That's exactly what companies like Parsyl are beginning to do. For the past two years, we've partnered with Gavi, the global vaccine alliance, to ship vaccines with sensors that can detect breaks in the cold chain before they lead to irreversible damage. What those sensors have taught us is remarkable. You might assume that the biggest threat to vaccines in the cold chain is heat. In fact, the opposite is true; our data show that freezing temperatures from ice-cooled vaccine carriers and faulty refrigerators pose a far greater risk. In one country, vaccines had a nearly one-in-four chance of spoiling due to freezing temperatures. By including sensors in all vaccine shipments, companies like Parsyl will benefit. But we can also enable targeted interventions like identifying and replacing the tens of thousands of old fridges destroying vaccines right nowthat are only possible with more precise data. Gavi has already created an initiative to replace cold chain equipment around the world; better data will help it target these urgently needed upgrades and improvements more effectively. Shipment-level data also allows for innovative ways to manage and transfer risk. Under the ship-and-pray model, insuring vaccine stockpiles in developing countries is prohibitively expensive because underwriters are flying blind. But with a sensor that can monitor and beam temperature information to the cloud, health workers on the ground will have the insights they need to prevent losses from occurring, and underwriters can accurately model risk. This is the idea behind the Global Health Risk Facility we announced last week with Lloyd's of London, which will insure COVID-19 vaccine delivery to developing countries. But perhaps the biggest surprise in our data was what could happen if we could simply deliver vaccines faster. If we're able to cut the time vaccines spend in the cold chain, especially in the so-called last mile, we could reduce spoilage by nearly 40%. One effective but underutilized way to speed up the supply chain is to enlist local logistics firms to deliver the goods. When vaccine distribution in three Ugandan districts serving over 3 million people was handed over to an East African logistics company, Freight in Time (which uses Parsyl's sensors), stockouts ended and the lead time needed for new vaccine shipments was cut from one month to five days. As a result, Freight in Time increased monthly vaccine distribution by 100,000 doses while cutting the number of wasted vials. Embracing these bold approachesbetter data, targeted interventions, smarter risk management, more trust in local partnerscan mean the difference between billions of people receiving potent vaccines or a COVID-19 crisis that lives on long after a vaccine is discovered. Unless we care as much about the delivery as we do about the cure, we will never be free of COVID-19. Case Study Read the above article, write a proposal to improve the vaccine delivery process with ICT: 1 Identify the problem in current vaccine delivery process By considering the characteristics in a cold supply chain, discuss the types of ICT you propose for vaccine delivery, and how your proposed technology can be used to improve the vaccine delivery process Discuss the benefits and challenges that may be faced when implementing your proposed technology in the cold supply chain. 1