Question: Case Study - ORION Systems Background The office erupts into cheers when it is announced over the PA system that ORION has just been awarded

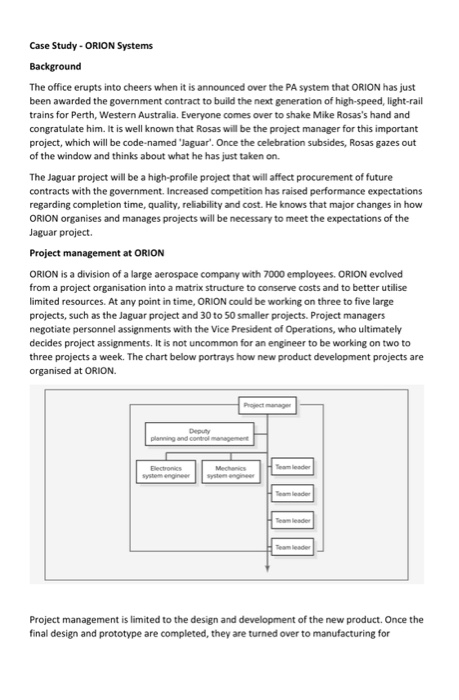

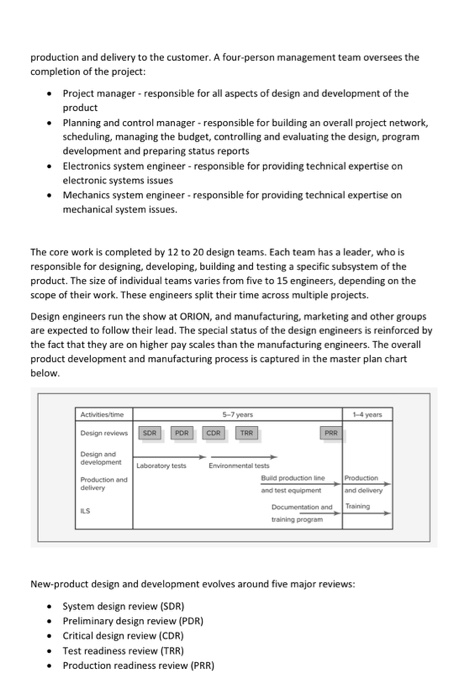

Case Study - ORION Systems Background The office erupts into cheers when it is announced over the PA system that ORION has just been awarded the government contract to build the next generation of high-speed, light-rail trains for Perth, Western Australia. Everyone comes over to shake Mike Rosas's hand and congratulate him. It is well known that Rosas will be the project manager for this important project, which will be code-named 'Jaguar'. Once the celebration subsides, Rosas gazes out of the window and think about what he has just taken on. The Jaguar project will be a high-profile project that will affect procurement of future contracts with the government. Increased competition has raised performance expectations regarding completion time, quality, reliability and cost. He knows that major changes in how ORION organises and manages projects will be necessary to meet the expectations of the Jaguar project. Project management at ORION ORION is a division of a large aerospace company with 7000 employees. ORION evolved from a project organisation into a matrix structure to conserve costs and to better utilise limited resources. At any point in time, ORION could be working on three to five large projects, such as the Jaguar project and 30 to 50 smaller projects. Project managers negotiate personnel assignments with the Vice President of Operations, who ultimately decides project assignments. It is not uncommon for an engineer to be working on two to three projects a week. The chart below portrays how new product development projects are organised at ORION Deputy planning and control managem Electronics Team leader sem engineer Team leader Project management is limited to the design and development of the new product. Once the final design and prototype are completed, they are turned over to manufacturing for production and delivery to the customer. A four-person management team oversees the completion of the project: Project manager - responsible for all aspects of design and development of the product Planning and control manager - responsible for building an overall project network, scheduling, managing the budget, controlling and evaluating the design, program development and preparing status reports Electronics system engineer - responsible for providing technical expertise on electronic systems issues Mechanics system engineer - responsible for providing technical expertise on mechanical system issues. The core work is completed by 12 to 20 design teams. Each team has a leader, who is responsible for designing, developing, building and testing a specific subsystem of the product. The size of individual teams varies from five to 15 engineers, depending on the scope of their work. These engineers split their time across multiple projects. Design engineers run the show at ORION, and manufacturing, marketing and other groups are expected to follow their lead. The special status of the design engineers is reinforced by the fact that they are on higher pay scales than the manufacturing engineers. The overall product development and manufacturing process is captured in the master plan chart below. Activities/time 5-7 years 1-4 years Design reviews SOR POR CDR TRR PRR Design and development Laboratory tests Production and delivery Environmental tests Bulld production line Production and test quipment and delivery Documentation and Training training program ILS New-product design and development evolves around five major reviews: System design review (SDR) Preliminary design review (PDR) Critical design review (CDR) Test readiness review (TRR) Production readiness review (PRR) Design and development work begins within the laboratory and progresses to field tests of specific subsystems and ultimately final product prototypes. Once completed, the design and prototype are turned over to manufacturing, which begins building the production line for the new product. Manufacturing also develops the necessary test equipment to confirm that manufactured components perform correctly. During this time, integrated logistical support (ILS) teams prepare product documentation, users' manuals, maintenance programs and training programs for the customers who will be using the product. ORION completes a major assessment of how its projects are being managed and below is a brief description of some of the major problems that are identified: Higher than expected production costs: Once products are developed, there is a tendency for them to be thrown over the wall to the manufacturing department for them to produce. Very little design for manufacturability is done, and the production ramp is complicated, inefficient and stressful for the people in the plant. Quality concerns: Increased competition has raised customer expectations with regard to quality. Customers expect fewer defects and longer replacement Schedules. ORION has a tendency to deal with quality issues after the fact; initiating quality improvements after the production process is set up. Not enough attention is devoted to incorporating quality considerations into the original design of products. Problems with customer support: User manuals and technical documentation sometimes fail to address all of a customer's concerns, and customer support follow- up training is not always adequately prepared. These problems have contributed to increased costs in customer service and a decline in customer satisfaction. Lack of strong project ownership: While everyone accepts that a matrix arrangement is the only way Page 157 to accommodate all the projects at ORION, the shifting back and forth of personnel across multiple projects is taking its toll on the progress of individual projects. Members often fail to identify with individual projects or develop a 'sense of excitement that could contribute to superior performance. The "shuffling' of personnel slows progress because additional time has to be devoted to bringing returning members up to speed on current developments. Scope creep: ORION is renowned for its engineering prowess. However, there is a tendency for design engineers to get so absorbed with the science of the project that they lose some focus around the practical considerations. This has led to costly delays and, sometimes, design modifications that are inconsistent with customer requirements. Rosas is aware of these and other concerns as he sits down with his staff to figure out the best way to organise the new Jaguar project. Questions 1. What recommendations would you make to Rosas about organising the Jaguar project, and why? 2. How would you change the organisational Chart and Master Plan to reflect these changes