Question: CASE STUDY Should Packing Be Postponed to the DC ? Penang Electronics ( PE ) is a contract manufacturer that produces and packages private -

CASE STUDY

Should Packing Be Postponed to the DC

Penang Electronics PE is a contract manufacturer that

produces and packages privatelabel products for several

retail chains, including Target, Best Buy, Staples, and

Office Max. In each case, the basic products are identi

cal, with the only difference being the labeling and the

packaging. Thus, the labeled and packed version of the

product destined for Target cannot be sent to Best Buy.

Currently, a production facility in Malaysia is used

to manufacture, label, and pack all products. The manu

facturing facility replenishes a DC in St Louis, from

which the contract manufacturer fills all customer

orders. The manufacturing and transportation lead time

from Penang to St Louis is nine weeks. PE uses a con

tinuous review policy to manage inventories at its DC

and aims to provide a cycle service level of percent

for each product to every customer.

The previous month had been very challenging

because Best Buy requested additional units

beyond what was available at the DC whereas Target

ordered fewer units and Staples ordered

fewer units. Even though there was sufficient product

inventory available at the DC in the form of the basic

product PE could not meet the Best Buy request because

the excess inventory available was labeled and packed for

other customers. The DC had leftover inventory from

Target and Staples, which unfortunately could not be

used to serve Best Buy. PE had lost business and surplus

inventory all because of the wrong labels and packaging.

Labeling and Packaging at the DC

The vice president of supply chain at PE proposed post

poning the final labeling and packaging to the DC Her

logic was that postponing labeling and packaging to the

DC would allow PE to use all available inventories to serve

any customer. In particular, the situation that arose in the

previous month when Best Buy did not get its entire order

could have been avoided through postponement. If packag

ing was shifted to the DC the lead time of manufacturing

and transporting the basic product from Malaysia would

continue to be about nine weeks. Labeling and packaging

were relatively quick steps and the response time from the

DC to the customer was not expected to change.

The DC management was opposed to this idea

because it would add additional work that was different

from what they had done so far. A detailed study of the

production process had shown that labeling and packag

ing at the DC cost $ per unit more than the cost of label

ing and packaging in Malaysia. DC management believed

that this increase in cost would be held against them once

the process was changed, and they would be under con

stant pressure to lower cost. They also believed it would

complicate the work they did when filling an order and

could adversely impact customer service.

Evaluating the Two Options

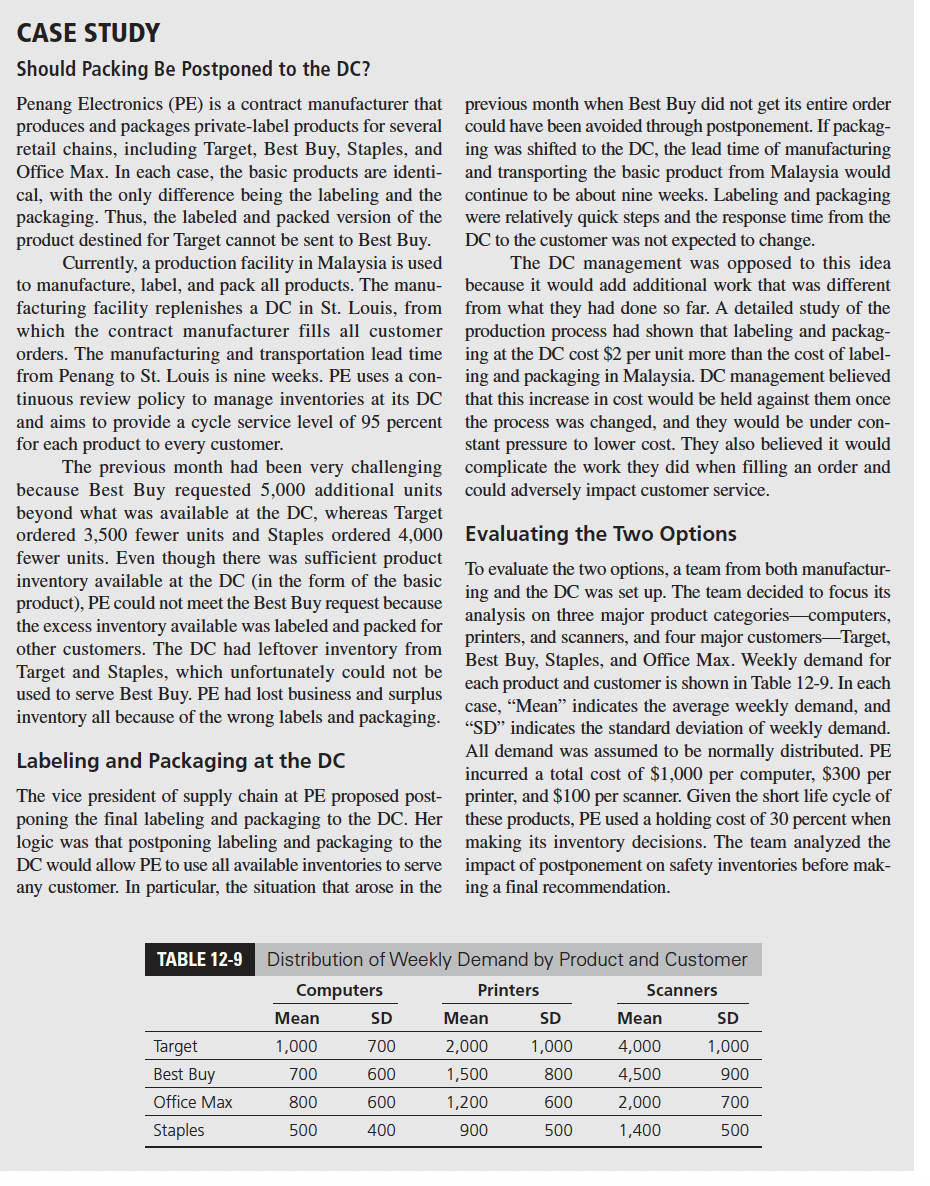

To evaluate the two options, a team from both manufactur

ing and the DC was set up The team decided to focus its

analysis on three major product categoriescomputers,

printers, and scanners, and four major customersTarget,

Best Buy, Staples, and Office Max. Weekly demand for

each product and customer is shown in Table In each

case, "Mean" indicates the average weekly demand, and

SD indicates the standard deviation of weekly demand.

All demand was assumed to be normally distributed. PE

incurred a total cost of $ per computer, $ per

printer, and $ per scanner. Given the short life cycle of

these products, used a holding cost of percent when

making its inventory decisions. The team analyzed the

impact of postponement on safety inventories before mak

ing a final recommendation.

Questions

What is the annual inventory cost of the current system in

which product is produced, labeled, and packed in Malay

sia before being shipped to the DC

How would the inventory cost change if labeling and pack

aging were moved to the DC Evaluate the change in

inventory costs as the correlation coefficient of demand

between any pair of customers varies from to to

How should PE set up its production, labeling, and pack

aging processes? Does your answer change if the addi

tional cost of labeling and packaging at the DC is reduced

to $from the current value of $

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock