Question: CHAPTER 1: PROJECT BACKGROUND This chapter provides the information about the project, the project objectives, an information about the company, the projects scope and limitations

CHAPTER 1: PROJECT BACKGROUND

This chapter provides the information about the project, the project objectives, an information about the company, the projects scope and limitations and the project development. This chapter also discusses the problems that the company is encountering and how they were determined by the proponents.

-

The Project

According to Azseo (2017), the Printing Press is one of the most important technological breakthroughs in the history of humankind. Its invention is described, in addition to the changes the press underwent throughout its history. The impact on the history of humankind is also analyzed. The printing press made it easier to get information and documents to be printed. Also, the printing press made it simpler to get data and archives to be printed. Instead of the information being duplicated by hand, the printing press made it possible to print various duplicates without a moment's delay. We live in a digital era, where it may seem that print has lost its value. But, thats not true. Be it advertising or packaging, printing services is essential to support the functioning of various sectors. Its an important channel that increases reach and helps in spreading information.

NOR1 Express Printing Services is a sole proprietorship company that prints anything on paper. The company also has expertise in printing receipts, flyers, posters, coffee/soap boxes, newsletters, souvenir programs, notebooks, diaries, company packaging boxes, and election materials.

Accumulation of data is made via Online Interview and Online Observation.The data gathered by the proponents was analyzed through the use of a pareto chart that showed the most common problems of NOR1 Express Printing Services. The company has been encountering 60.93% Defects, 31.96% Extra Processing when printing papers and 1.67% Idle Time in the pre-press, press, and post-press area. Other negligible problems included Unnecessary Motion, No PPEs, Scattered Scraps, Old Machines, Lack of Inspection, Lack of Manpower, Unorganized Workplace, and Wrong Method of Inspection. As a result, the company has a potential loss of Php. 9,020.00 worth of receipt paper and ink usage per month, or Php 108,240.00 per year plus Php 30,000.00 loss from packaging paper cost and discount (20,000 loss from packaging paper cost and 10,000 loss because of discount) because of defects of packaging paper. This was despite the fact that the company had a capacity of making 3,500 papers per hour in baby offset machines, 5000 papers per hour in offset machines, and 300 paper per hour in folding packaging paper via die cut machine.

-

Project Objectives

The project aims to design an optimized production and management system to minimize defects and extra processing in NOR1 Express Printing Services in accordance with engineering standards and with consideration of trade-offs based on multiple realistic constraints, such as economic, safety, environmental, sustainability, and risk.

Specifically, the proponents aim to:

-

Identify the current process of NOR1 Express Printing Services in printing papers.

-

Identify the causes of problems using root cause analysis tools .

-

Create three (3) designs that can eliminate the problems.

-

Analyze the three (3) designs with alternatives to remedy existing problems.

-

Choose the most beneficial alternative design.

-

Apply the design alternative.

-

Give conclusions and make recommendations.

-

The Client

Figure 1.3.1 Company Logo

NOR1 Printing Services is a sole entrepreneur printing company. The term NOR1 came from the owners mother and father whose names are Nora and Juan. NOR1 Express Printing Services was born at Molave Street, Project 3, Quezon City in 2010. At that time, there were only printing machines and 1 small cheap laptop for layouting. The owner or the manager of the company is a former medical technology graduate and worked overseas as medtech. When the mother of the owner died, the owner took over the house since no one would take care of the house and started a printing company in the house of his late mother and father. Eventually, the owner moved out to expand the business. Currently, she owns 5 computers (2 used for layouting, 2 for facilitating CTP, 1 for owners personal computer), xerox machine, CTP Plate Printing, Developer, 2 Offset machines, Die-cut machine, Cutting Machine, 3 baby offset machine (2 currently outside the plant). The company prints anything on paper. The company also specializes in printing receipts, flyers, posters, coffee/soap boxes, newsletters, souvenir programs, notebooks, diaries, company packaging boxes, and election materials.The major clients of NOR1 Printing Services are Advent Manila Hospitality Group Incorporated, Network Consolidated Cooperative Bank (NCCB), Avast Orchard Montessori, Learn & Play School, Smart Aid Diagnostic, and Ice Cream House. The competitors of the company are Palbros Printing Shop, Paus Printing Press, TGF&S Printing Services which also located in same location and other nearby printing businesses. The company has a total of 6 workers.

-

Project Scope and Limitations

The scope of this project is to create a new design and system that will improve the flow of the process in PRE-PRESS, PRESS and POST-PRESS in printing papers. The project only focuses on the data provided by the client. The proponents used pareto chart, ishikawa diagram, problem tree, and objective tree to identify the potential problems in the three areas of printing processes. The proponents focused on the receipt paper and did not take into account the vital few problems because they were considered to be minor issues . The owner also does not want to give the companys financial statement due to confidentiality of information.

Appendix A: Pareto Chart

Table A: Pareto Table

| Problems | Frequency | Percent | Cumulative Percentage |

| DEFECTS | 1750 | 60.93% | 60.93% |

| EXTRA PROCESSING | 918 | 31.96% | 92.90% |

| IDLE TIME | 48 | 1.67% | 94.57% |

| UNNECESSARY MOTION | 36 | 1.25% | 95.82% |

| NO PPE | 36 | 1.25% | 97.08% |

| SCATTERED SCRAPS | 30 | 1.04% | 98.12% |

| OLD MACHINE | 18 | 0.63% | 98.75% |

| LACK OF INSPECTION | 12 | 0.42% | 99.16% |

| LACK OF MANPOWER | 12 | 0.42% | 99.58% |

| UNORGANIZED WORKPLACE | 6 | 0.21% | 99.79% |

| WRONG METHOD OF INSPECTION | 6 | 0.21% | 100.00% |

| TOTAL | 2872 | 100.00% |

The above table shows the different problems that the proponents were able to observe in the NOR1 EXPRESS PRINTING SERVICES. It was found that the most common problem is the DEFECTS(60,93%) , followed by EXTRA PROCESSING (31.96%) and IDLE TIME (1.67%) which were considered to be vital few of the problems, proceeding in a cumulative percentage of 94.57%

Figure A: Pareto Chart

Based on the result of the Pareto chart, 60.9% of the problem lies in the number of defects followed by the number of extra processing. The proponents will focus on finding innovative solutions to minimize the problem.

Appendix B: Ishikawa Diagram

Figure B: Ishikawa Diagram

| DESCRIPTION | CONTROLLABLE | UNCONTROLLABLE |

| 1. MAN | ||

| 1.1 Lack of Staff |

| |

| 1.2 Human Error |

| |

| 1.3 Lack of Skill |

| |

| 1.4 Lack of Training |

| |

| 2. METHODS | ||

| 2.1 Wrong Process |

| |

| 2.2 Extra Processing |

| |

| 2.3 No Inspection |

| |

| 3. MILIEU | ||

| 3.1 Not well ventilated |

| |

| 3.2 Workers cant move freely |

| |

| 4. MACHINE | ||

| 4.1 Old Machine |

| |

| 4.2 Lack of Inspection |

| |

| 5. MEASUREMENT | ||

| 5.1 Tight Hallway |

| |

| 5.2 Machines are not well Organized |

| |

| 5.3 Available storage for finished products |

| |

| 6. MATERIALS | ||

| 6.1 Paper Prone on wrinkling |

| |

| 7. MANAGEMENT | ||

| 7.1 No financial records |

| |

| 7.2 No supervision |

| |

| 8. MAINTENANCE | ||

| 8.1 Self Maintenance |

| |

| 8.2 No proper people assigned to maintain machine |

|

The Ishikawa Diagram shows the root causes of the delay within the approval of requests. These root causes are categorized between, man,

Appendix C: Tree Diagram

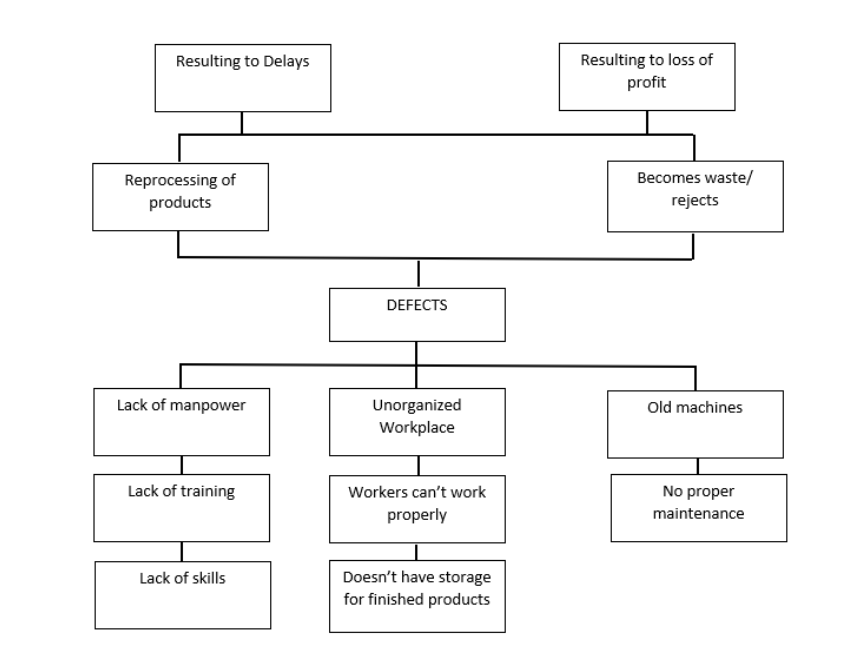

Figure C: Problem Tree

Within the NOR1 Express Printing Services, the tree diagram depicts the problem's cause, problem, and effect. This figure describes what will happen if no changes are made.

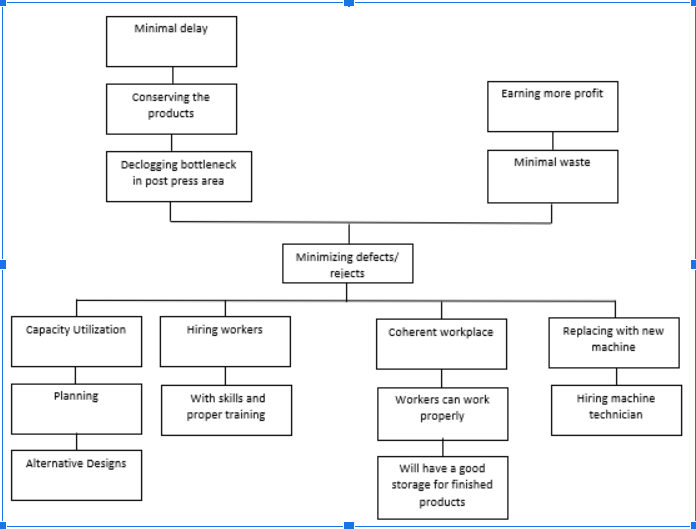

Figure D: Objective Tree

The converted solutions to the identified problems are depicted in the figure above.

MATERIAL COST = 108,240PHP YEARLY

LABOR COST= 521,964PHP YEARLY

COMPANY EARNINGS YEARLY = 1,080,000 PHP

The pareto chart in the given case, portrays the different problems which are observed by the proponents in the course of study to improve the overall printing process. Every problem identified by the proponents can attribute to certain amount of rework conducted by the company. The rework will have resources labor as well as material, involved as to solve the problem and improve the printing process. The labor cost as well as the material cost associated in the rework can be calculated on pro-rata basis and associated with the problems affecting the company. So we will get a monetary table of rework done, associated with the problems identified in the Pareto Chart.

QUESTION PLEASE HOW CAN WE MAKE OUR PARETO CHART IN MONETARY UNIT FORM?

Resulting to Delays Resulting to loss of profit Reprocessing of products Becomes waste rejects DEFECTS Lack of manpower Unorganized Workplace Old machines Lack of training Workers can't work properly No proper maintenance Lack of skills Doesn't have storage for finished products Minimal delay Earning more profit Conserving the products Minimal waste Declogging bottleneck in post press area Minimizing defects/ rejects Capacity Utilization Hiring workers Coherent workplace Replacing with new machine Planning With skills and proper training Workers can work properly Hiring machine technician Alternative Designs will have a good storage for finished productsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts