Question: CHAPTER 11 - Case Study Capacity Management Fine Country Fruit Cakes September 2017 was a year to remember for Jean and Dave Fulbright! Their twin

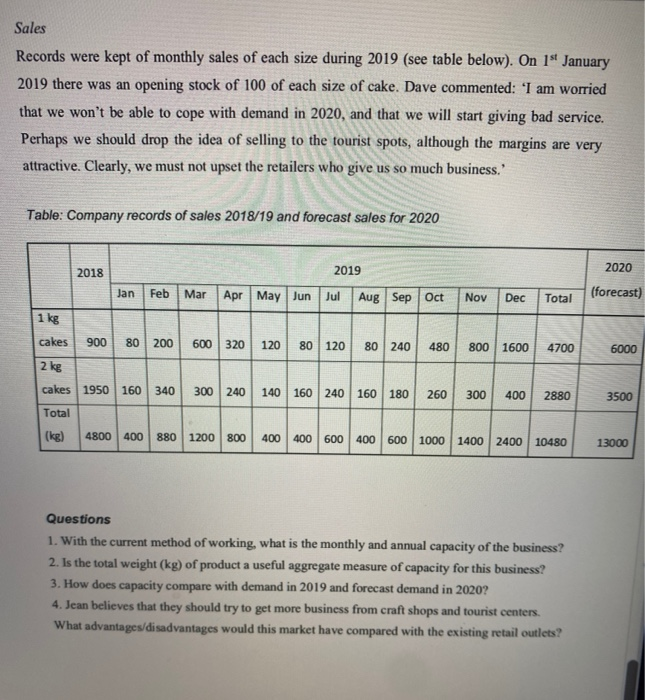

CHAPTER 11 - Case Study Capacity Management Fine Country Fruit Cakes September 2017 was a year to remember for Jean and Dave Fulbright! Their twin sons, Michael and Alan, then five years old, started school, and in the same month, Dave, a 29-year-old master baker at a large bakery, was made redundant. Jean, who had a part-time secretarial job with a local builder, saw this misfortune to be an unrepeatable opportunity. They had always wanted to work together, and it seemed to be a good chance to set up a small specialty business, based on Dave's skills and financed by his redundancy payments plus a small loan. Traditionally, small local baking and confectionery businesses produce a wide range of breads, cakes, biscuits, etc., many on a daily basis. This involves a very early start (4 am), high complexity and considerable risk. Dave wanted a 'simpler' business that would involve relatively normal hours of work, for both himself and his wife. Neither wanted to be employers, the business would be run by just the two of them. Dave felt that his greatest satisfaction came from producing high-quality decorated fruit cakes, so together they decided that there was an opportunity to specialize in this product. Using an old family recipe, samples were made and packaged. "Market research was confined to taking these samples to various retail outlets in the area; the reaction was so enthusiastic, and the potential margin seemed so high, that by January 2017 they were in business. They rented a small modem factory near home, modestly equipped with weighing and preparation equipment, a large 15 kg food mixer, two small catering ovens, a small cool room and sundry utensils. Later, Dave recalled: "In early 2018 we only made one size: beautiful 2 kg cakes, symmetrically decorated on top with a patter of almonds, cherries, and walnuts and ginger. We sold most to cafs and restaurants their customers loved portions of them with their teas/coffees. Demand ran at about 150-200 cakes a month, which wasn't enough to make much of a living, but we had time to visit our customers and to try new outlets. Although sales were growing, it gradually became clear that we should be selling a smaller cake to retail shops for family purchasers - one which could be bought as a treat, or as a gift for friends. We introduced the I kg cake (with the same recipe) in July 2018. We had no problems selling these, and demand soon exceeded all our expectations. The delicatessens in the area heard about our products and soon sales of the 1 kg cake overtook those of the original 2 kg cake. Somehow, however, it's not been so easy running the business since then; we can only just cope every day making the cakes. Jean can go to get the children from school at about 3.30 pm (a neighbor takes them in the morning) but I rarely get back before 7:00 pm in the week; and we usually do our selling and prospecting for new customers on Saturdays. We certainly don't want to start production at weekends; we couldn't cope with that! Anyway, although we're making a reasonable profit now, I feel we could do a better job somehow. There were times last year (2019) when we had over-produced and we had to sell off some stock at a discount because of its age. Tests have shown that this recipe of rich fruit cakes lasts for up to 12 months, but for best flavor and texture, it should really be eaten within six months. The retailers demand at least three months of this, so I can't keep stock more than three months here at the factory. Anyway, I only have space for about 3000 kg in the cool room, allowing for stock rotation." Jean's view of the business was somewhat different: 'I think we are chasing the wrong markets! The delicatessens demand big discounts and are always expecting us to deliver at short notice, particularly around Easter (March/April) and at Christmas (November/December) when the cakes are apparently popular gifts. I have found th craft shops and visitor centers of local tourist spots (such as castles and historic houses) can also sell our 1 kg cakes and, moreover, they don't expect much discount! We were really pleased with the level of orders from these outlets last summer, but we don't hear from them much during the winter. I really should go and take some more samples! I also feel we should open a factory shop where regular users could come and buy directly, but I am sure we would need to provide a bigger range of cakes. We could develop lots of different types in the two sizes - then we would get a lot more repeat business!" Production Preparation In order to simplify weighing, mixing and baking, all production is done in nominal 10 kg batches of one size at a time. Thus a batch is either ten 1 kg cakes or five 2 kg cakes. For each batch, dried fruits (raisins, sultanas, currants, cherries, crystallized ginger, etc.) are weighed and cleaned as necessary, other ingredients are prepared and measured, and a cake mixture is made in the mixer. Tins are greased, and the mixture is weighed into each; the top surface is then decorated with carefully selected specimen dried fruits and nuts, and brushed with a glaze. This complete preparation stage takes almost exactly 30 minutes per batch for Dave and Jean working as a team, for either size of cake. Each batch is prepared just before the oven is ready to accept it, to avoid contamination and to maintain consistency of method, and hence of texture. Baking The ovens are tumed on at 8.00 am and are ready by 8.30 when the first batch is loaded (which only takes a few minutes). A 10 kg batch of cakes fills one oven; baking time is three hours for the 1 kg cakes, four and a half hours for 2 kg cakes. When ready, the cakes are removed from the hot oven, which is ready for a further batch in a quarter of an hour. For convenience, Dave has always baked the 1 kg cakes in the oldest oven (Oven 1) to avoid having to carry 10 tins to Oven 2 which is further from the workbench. Each oven normally bakes only two batches per day. Dave thinks that the temperature control on Oven 1 is inaccurate which would be a particular problem for the larger size cakes! Packing Cakes are turned out onto racks to cool overnight. The next day, once the first batches are in the oven, the previous day's cakes are inspected, packed in a film, a decorative ribbon and an outer- wrap, and then labelled and dated. Packed cakes are then carried to the coolroom and stacked according to size. These processes take two people six minutes per cake (either size). The couple take one hour for lunch from 12.30 to 1.30 pm (when Oven 2 is ready to unload). Planning "The only times in 2019 that we changed production were in March, April, November and December when we increased 2 kg output only by 50 per cent (one extra batch per day). I had to bake the 2 kg cakes in Oven and the quality wasn't really so good, but one of our regular customers noticed! Even so, I had to work into the evenings all those months was a lot of work. All other months we have kept to the plan of two batches of each size each day (1ks, followed by 2 kg. 1 kg.2 kg) which helps us keep to a thythm Sales Records were kept of monthly sales of each size during 2019 (see table below). On 1st January 2019 there was an opening stock of 100 of each size of cake. Dave commented: 'I am worried that we won't be able to cope with demand in 2020, and that we will start giving bad service. Perhaps we should drop the idea of selling to the tourist spots, although the margins are very attractive. Clearly, we must not upset the retailers who give us so much business." Table: Company records of sales 2018/19 and forecast sales for 2020 2018 2019 2020 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec (forecast) Total 1 kg cakes 900 80200 600 320 120 80 120 80 240 480 800 1600 4700 6000 12 kg cakes 1950 160 340 300 240 140 160 240 160 180 260 300 400 2880 3500 Total (kg) 4800 400 880 | 1200 800 400 400 600 400 600 1000 1400 2400 10480 13000 Questions 1. With the current method of working, what is the monthly and annual capacity of the business? 2. Is the total weight (kg) of product a useful aggregate measure of capacity for this business? 3. How does capacity compare with demand in 2019 and forecast demand in 2020? 4. Jean believes that they should try to get more business from craft shops and tourist centers. What advantages/disadvantages would this market have compared with the existing retail outlets? CHAPTER 11 - Case Study Capacity Management Fine Country Fruit Cakes September 2017 was a year to remember for Jean and Dave Fulbright! Their twin sons, Michael and Alan, then five years old, started school, and in the same month, Dave, a 29-year-old master baker at a large bakery, was made redundant. Jean, who had a part-time secretarial job with a local builder, saw this misfortune to be an unrepeatable opportunity. They had always wanted to work together, and it seemed to be a good chance to set up a small specialty business, based on Dave's skills and financed by his redundancy payments plus a small loan. Traditionally, small local baking and confectionery businesses produce a wide range of breads, cakes, biscuits, etc., many on a daily basis. This involves a very early start (4 am), high complexity and considerable risk. Dave wanted a 'simpler' business that would involve relatively normal hours of work, for both himself and his wife. Neither wanted to be employers, the business would be run by just the two of them. Dave felt that his greatest satisfaction came from producing high-quality decorated fruit cakes, so together they decided that there was an opportunity to specialize in this product. Using an old family recipe, samples were made and packaged. "Market research was confined to taking these samples to various retail outlets in the area; the reaction was so enthusiastic, and the potential margin seemed so high, that by January 2017 they were in business. They rented a small modem factory near home, modestly equipped with weighing and preparation equipment, a large 15 kg food mixer, two small catering ovens, a small cool room and sundry utensils. Later, Dave recalled: "In early 2018 we only made one size: beautiful 2 kg cakes, symmetrically decorated on top with a patter of almonds, cherries, and walnuts and ginger. We sold most to cafs and restaurants their customers loved portions of them with their teas/coffees. Demand ran at about 150-200 cakes a month, which wasn't enough to make much of a living, but we had time to visit our customers and to try new outlets. Although sales were growing, it gradually became clear that we should be selling a smaller cake to retail shops for family purchasers - one which could be bought as a treat, or as a gift for friends. We introduced the I kg cake (with the same recipe) in July 2018. We had no problems selling these, and demand soon exceeded all our expectations. The delicatessens in the area heard about our products and soon sales of the 1 kg cake overtook those of the original 2 kg cake. Somehow, however, it's not been so easy running the business since then; we can only just cope every day making the cakes. Jean can go to get the children from school at about 3.30 pm (a neighbor takes them in the morning) but I rarely get back before 7:00 pm in the week; and we usually do our selling and prospecting for new customers on Saturdays. We certainly don't want to start production at weekends; we couldn't cope with that! Anyway, although we're making a reasonable profit now, I feel we could do a better job somehow. There were times last year (2019) when we had over-produced and we had to sell off some stock at a discount because of its age. Tests have shown that this recipe of rich fruit cakes lasts for up to 12 months, but for best flavor and texture, it should really be eaten within six months. The retailers demand at least three months of this, so I can't keep stock more than three months here at the factory. Anyway, I only have space for about 3000 kg in the cool room, allowing for stock rotation." Jean's view of the business was somewhat different: 'I think we are chasing the wrong markets! The delicatessens demand big discounts and are always expecting us to deliver at short notice, particularly around Easter (March/April) and at Christmas (November/December) when the cakes are apparently popular gifts. I have found th craft shops and visitor centers of local tourist spots (such as castles and historic houses) can also sell our 1 kg cakes and, moreover, they don't expect much discount! We were really pleased with the level of orders from these outlets last summer, but we don't hear from them much during the winter. I really should go and take some more samples! I also feel we should open a factory shop where regular users could come and buy directly, but I am sure we would need to provide a bigger range of cakes. We could develop lots of different types in the two sizes - then we would get a lot more repeat business!" Production Preparation In order to simplify weighing, mixing and baking, all production is done in nominal 10 kg batches of one size at a time. Thus a batch is either ten 1 kg cakes or five 2 kg cakes. For each batch, dried fruits (raisins, sultanas, currants, cherries, crystallized ginger, etc.) are weighed and cleaned as necessary, other ingredients are prepared and measured, and a cake mixture is made in the mixer. Tins are greased, and the mixture is weighed into each; the top surface is then decorated with carefully selected specimen dried fruits and nuts, and brushed with a glaze. This complete preparation stage takes almost exactly 30 minutes per batch for Dave and Jean working as a team, for either size of cake. Each batch is prepared just before the oven is ready to accept it, to avoid contamination and to maintain consistency of method, and hence of texture. Baking The ovens are tumed on at 8.00 am and are ready by 8.30 when the first batch is loaded (which only takes a few minutes). A 10 kg batch of cakes fills one oven; baking time is three hours for the 1 kg cakes, four and a half hours for 2 kg cakes. When ready, the cakes are removed from the hot oven, which is ready for a further batch in a quarter of an hour. For convenience, Dave has always baked the 1 kg cakes in the oldest oven (Oven 1) to avoid having to carry 10 tins to Oven 2 which is further from the workbench. Each oven normally bakes only two batches per day. Dave thinks that the temperature control on Oven 1 is inaccurate which would be a particular problem for the larger size cakes! Packing Cakes are turned out onto racks to cool overnight. The next day, once the first batches are in the oven, the previous day's cakes are inspected, packed in a film, a decorative ribbon and an outer- wrap, and then labelled and dated. Packed cakes are then carried to the coolroom and stacked according to size. These processes take two people six minutes per cake (either size). The couple take one hour for lunch from 12.30 to 1.30 pm (when Oven 2 is ready to unload). Planning "The only times in 2019 that we changed production were in March, April, November and December when we increased 2 kg output only by 50 per cent (one extra batch per day). I had to bake the 2 kg cakes in Oven and the quality wasn't really so good, but one of our regular customers noticed! Even so, I had to work into the evenings all those months was a lot of work. All other months we have kept to the plan of two batches of each size each day (1ks, followed by 2 kg. 1 kg.2 kg) which helps us keep to a thythm Sales Records were kept of monthly sales of each size during 2019 (see table below). On 1st January 2019 there was an opening stock of 100 of each size of cake. Dave commented: 'I am worried that we won't be able to cope with demand in 2020, and that we will start giving bad service. Perhaps we should drop the idea of selling to the tourist spots, although the margins are very attractive. Clearly, we must not upset the retailers who give us so much business." Table: Company records of sales 2018/19 and forecast sales for 2020 2018 2019 2020 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec (forecast) Total 1 kg cakes 900 80200 600 320 120 80 120 80 240 480 800 1600 4700 6000 12 kg cakes 1950 160 340 300 240 140 160 240 160 180 260 300 400 2880 3500 Total (kg) 4800 400 880 | 1200 800 400 400 600 400 600 1000 1400 2400 10480 13000 Questions 1. With the current method of working, what is the monthly and annual capacity of the business? 2. Is the total weight (kg) of product a useful aggregate measure of capacity for this business? 3. How does capacity compare with demand in 2019 and forecast demand in 2020? 4. Jean believes that they should try to get more business from craft shops and tourist centers. What advantages/disadvantages would this market have compared with the existing retail outlets