Question: Chapter 8: Aggregate Planning in a Supply Chain A manufacturing company faces the aggregate planning problem for the next five months. The monthly demand

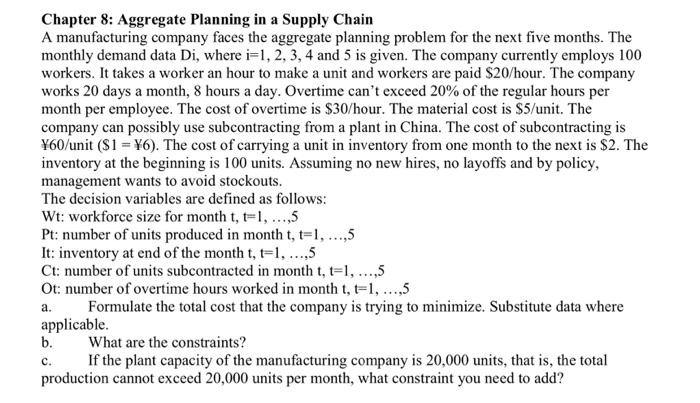

Chapter 8: Aggregate Planning in a Supply Chain A manufacturing company faces the aggregate planning problem for the next five months. The monthly demand data Di, where i=1, 2, 3, 4 and 5 is given. The company currently employs 100 workers. It takes a worker an hour to make a unit and workers are paid $20/hour. The company works 20 days a month, 8 hours a day. Overtime can't exceed 20% of the regular hours per month per employee. The cost of overtime is $30/hour. The material cost is $5/unit. The company can possibly use subcontracting from a plant in China. The cost of subcontracting is 60/unit ($1 = 6). The cost of carrying a unit in inventory from one month to the next is $2. The inventory at the beginning is 100 units. Assuming no new hires, no layoffs and by policy, management wants to avoid stockouts. The decision variables are defined as follows: Wt: workforce size for month t, t=1, ...,5 Pt: number of units produced in month t, t=1, ...,5 It: inventory at end of the month t, t-1, ...,5 Ct: number of units subcontracted in month t, t=1, ...,5 Ot: number of overtime hours worked in month t, t-1, ...,5 a. Formulate the total cost that the company is trying to minimize. Substitute data where applicable. b. C. What are the constraints? If the plant capacity of the manufacturing company is 20,000 units, that is, the total production cannot exceed 20,000 units per month, what constraint you need to add?

Step by Step Solution

3.40 Rating (163 Votes )

There are 3 Steps involved in it

a Salary cost per worker per month 20 days 8 hours a day 20 per hour 3200 ... View full answer

Get step-by-step solutions from verified subject matter experts