Question: CHEMICAL ENGINEERING KINETCS J . M . SMITH SECOND EDITION 1 3 - 8 . Design a reactor system to produce styrene by the vapor

CHEMICAL ENGINEERING KINETCS J M SMITH SECOND EDITION

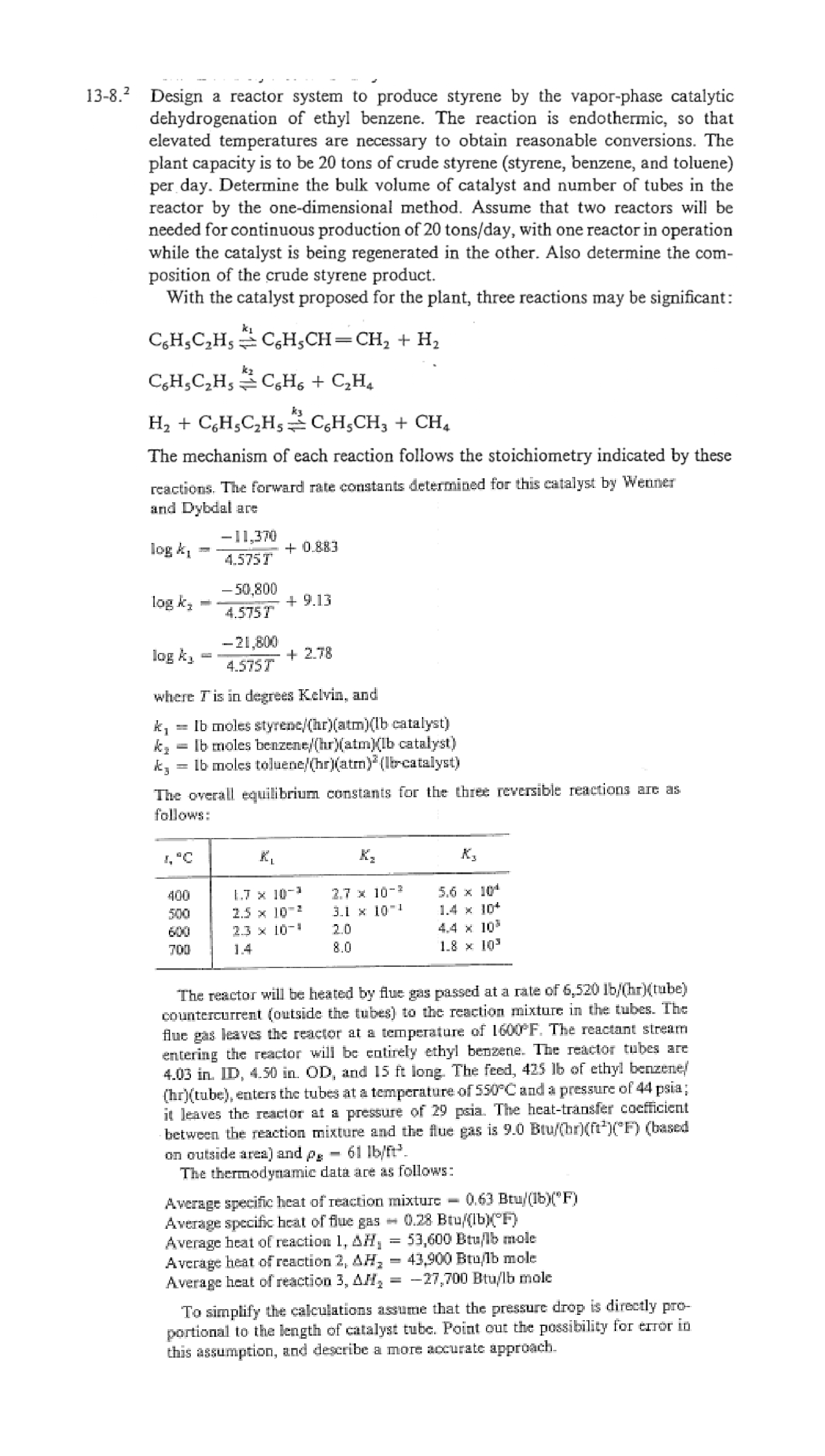

Design a reactor system to produce styrene by the vaporphase catalytic dehydrogenation of ethyl benzene. The reaction is endothermic, so that elevated temperatures are necessary to obtain reasonable conversions. The plant capacity is to be tons of crude styrene styrene benzene, and toluene per day. Determine the bulk volume of catalyst and number of tubes in the reactor by the onedimensional method. Assume that two reactors will be needed for continuous production of tonsday with one reactor in operation

while the catalyst is being regenerated in the other. Also determine the composition of the crude styrene product.

With the catalyst proposed for the plant, three reactions may be significant:

The mechanism of each reaction follows the stoichiometry indicated by these reactions. The forward rate constants determined for this catalyst by Wenner and Dybdal are:

where is in degrees Kelvin, and

moles styremehratmlb catalyst

Ib moles benzenehratmlb catalyst

moles toluenehrlb catalyst

The overall equilibrium constants for the three reversible reactions are as follows:

The reactor will be heated by flue gas passed at a rate of hrtube countercurrent outside the tubes to the reaction mixture in the tubes. The flue gas leaves the reactor at a temperature of The reactant streamentering the reactor will be entirely ethyl benzene. The reactor tubes are and long. The feed, of ethyl benzenehrtube enters the tubes at a temperature of and a pressure of psia; it leaves the reactor at a pressure of psia. The heattransfer coefficient between the reaction mixture and the flue gas is based on ouside area and

The thermodynamic data are as follows:

Average specific heat of reaction mixture Btu

Average specific heat of flue gas

Average heat of reaction mole

Average heat of reaction mole

Average heat of reaction mole

To simplify the calculations assume that the pressure drop is directly proportional to the length of catalyst tube. Point out the possibility for error in this assumption, and describe a more aocurate approach.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock