Question: Chick & Peas Limited - Case Study Challenge #1 C & P has charged you with the responsibility to offer solutions to existing problems, so

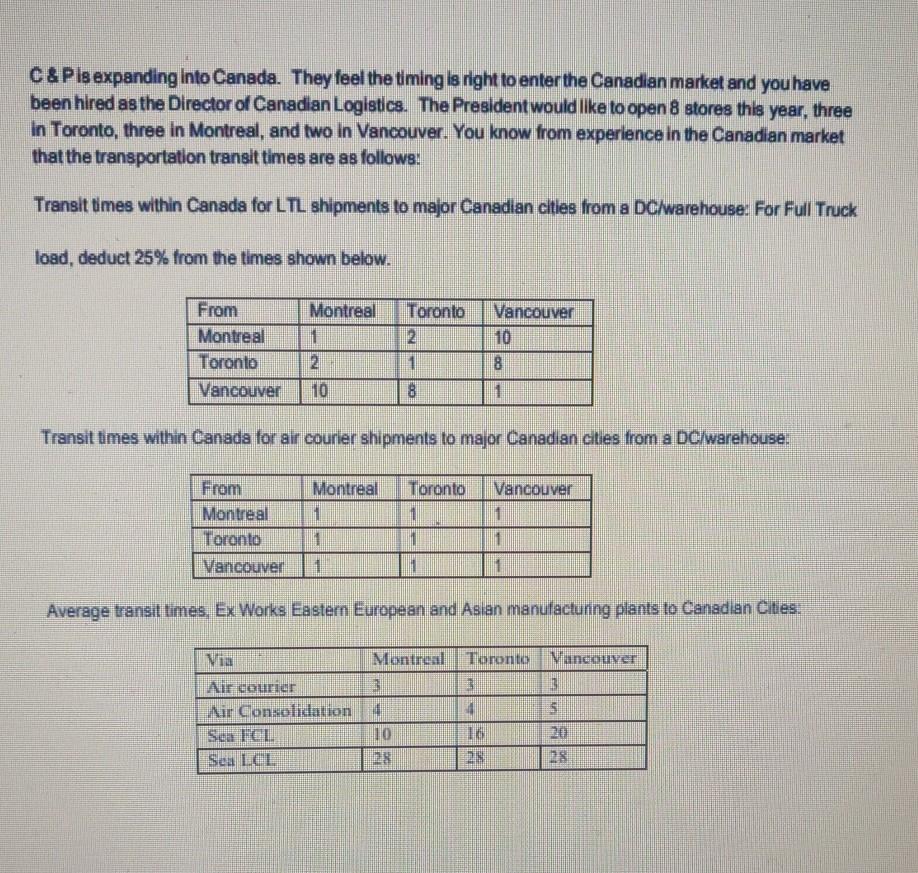

Chick & Peas Limited - Case Study Challenge #1 C & P has charged you with the responsibility to offer solutions to existing problems, so that the Canadian launch is a smooth one. You are responsible for creating a full distribution system for the Canadian market This includes modal selection, warehouse, or distribution centre selection, intermediaries, distributors; and communications, (specific to order processing, customs, or warehouse management requirements). When choosing the modes for the links in your system, consider the fact that you will be filling stores for the launch of the retail chain, and then replenishing thereafter. This distribution system must include a flow chart that is fully supported by an extensive, detailed, written explanation and support for each part of your supply chain selections. (The list of supply chain components listed in this paragraph is not exhaustive. You are free to reduce or increase the components, so long as you can justify the use or non-use of components. None of these components are mandated). The flow chart/system must start from plant(s), in Asia, and end at the retail site in Canada. Remember that the final delivery site will likely be a shopping mall with limited dock facilities, inside delivery requirements and reduced hours for delivery, including appointments for dock times. Your system must include and discuss quality control. The location of quality control points must be justified. You need to involve a minimum of 4 links and nodes, and if you chose to outsource this project to a 3 PL, you must fully describe your chosen 3 PL's supply chain. As we have not offered specific cities in Eastern Europe or in Asia, you can consider each (East Europe and Asia) as one node. Notes: this case study calls on your knowledge of modal characteristics and relevant strength and weaknesses within each mode or combination of modes. It also challenges your ability to create useful and efficient supply chain, employing all of the strengths, and benefits of intermediaries, warehousing, quality control and information sharing to make it work. We will not accept lists of features and benefits. We will not accept purely schematic representations of your proposal. We expect a detailed descriptive discussion of the makeup, and reasons for all components of your model. You may list assumptions. They will be evaluated for relevance. Although they are not required readings, you may use the transportation sections of your text to supplement your ideas and use the entire textbook as reference material, even chapters that have not yet been covered. Case Study - Chick & Peas Limited Chick & Peas Limited (C & P) is a global clothing retaller whose target market is almed at fourteen to thirty- year olds. Their head office is based in Paris, France. They sel over 600 million Items every year, from more than 2000 stores throughout Europe. It is the world's fourth largest clothing retailer, netting more than $560 million in 2008. C&P is best known for its reaction time and speed-It gets newly designed, trendy fashions to the market quickly. Its clothing is not made to last, and they pride themselves in designing, producing, and distributing their goods in less than 21 days. C&P is successful with both their men's and women's clothing line, because they get the latest fashion items to market quickly and sell them at extremely low prices. C & P contracts with the least expensive suppliers available, mostly in Asia and Eastern Europe, where it leverages its buying volume to reduce clothing costs and shorten lead tmes. The profit margin on products is between 300 - 500%. They use many suppliers simultaneously, reducing the risks involved in supplier failure, or related time delays. The same supplier may be contracted to manufacture for both the men's and the women's line. All C & P products are packaged and shipped in low cost corrugated boxes, with the C & P logo clearly visible on all sides. Designers of luxury brand fashions host lour fashion shows per year to display their collections. Photographs of these high fashion collections are available online immediately after a show. This relatively new method of Interpreting new designs and creating similar garments has revolutionized the retail garment market, enabling fast-fashion retailers like C & P to reduce the time span between the fashion shows and their debut at retail stores. Earlier, it took months for retailers to interpret designs by luxury labels for the general public. This has now created a new market segment supported by shoppers anxious for frequent replenishment of new clothing. C&P stores are restocked daily. Some high-volume stores get two delivers per day. The retail stores move so many products that they offer 22 fashion seasons per year! That means each season is just two weeks long. This level of activity has created a very stressful environment throughout C & P's supply chain. The primary transportation that C&Pemploys in Europe is courier. C& Pcurrently purchases on a DAP named store basis from manufacturer to stores. DAP is the new Incoterm for 2010 and it states that the seller is responsible to dear the goods for export and arrange and pay for the transportation to the named place. The seller bears all the nsk to the named place. The seller is not obligated to clear the goods for import pay duty or carry out any customs formalities. C&P allows factories to choose the shipping company. Recent industry reports have shown transportation costs are rising in the market and since C& Phave never been invoiced for this service. They have no real data to review. There are also times when they lose visibility of the packages as not all service providers share a common global system, Initial orders established by C&P Head Office for all new products are sent to each store directly Currently, data is gathered at C & P Head Office and then sent back to the factories via email every week, advising them what fashion tem(s) is projected to be in demand, so manufacturing can adjust according to the coming trends. C&Pls expanding Into Canada. They feel the timing is right to enter the Canadian market and you have been hired as the Director of Canadian Logistics. The President would like to open 8 stores this year, three in Toronto, three in Montreal, and two in Vancouver. You know from experlence in the Canadian market that the transportation transit times are as follows: Transit times within Canada for LTL shipments to major Canadian cities from a DC/warehouse: For Full Truck load, deduct 25% from the times shown below. Toronto 2 From Montreal Toronto Vancouver Montreal 1 2 10 Vancouver 10 8 8 1 Transit times within Canada for air courier shipments to major Canadian cities from a Dc/warehouse. From Montreal Toronto Vancouver Montreal 1 1 Toronto 1 Vancouver 1 1 1 1 1 Average transit times. Ex Works Eastern European and Asian manufacturing plants to Canadian Cities. Montreal Vancouver Toronto 3 3 Via Air courier Air Consolidation Sea FCI Sea LCE $ 10 Chick & Peas Limited Case Study Challenges . Create a full distribution system. Must include a flowchart with any extensive written explanation > Starts in Asia, ends at Canada retail location Quality control points along the supply chain

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock