Question: Civil Engineering - Construction Management - Construction Methods Using the following reference material, redo Exemple 6-1 on page 32 for a 1.5 cubic yard excavator

Civil Engineering - Construction Management - Construction Methods

Using the following reference material, redo Exemple 6-1 on page 32 for a 1.5 cubic yard excavator and ten -foot average depth of cut

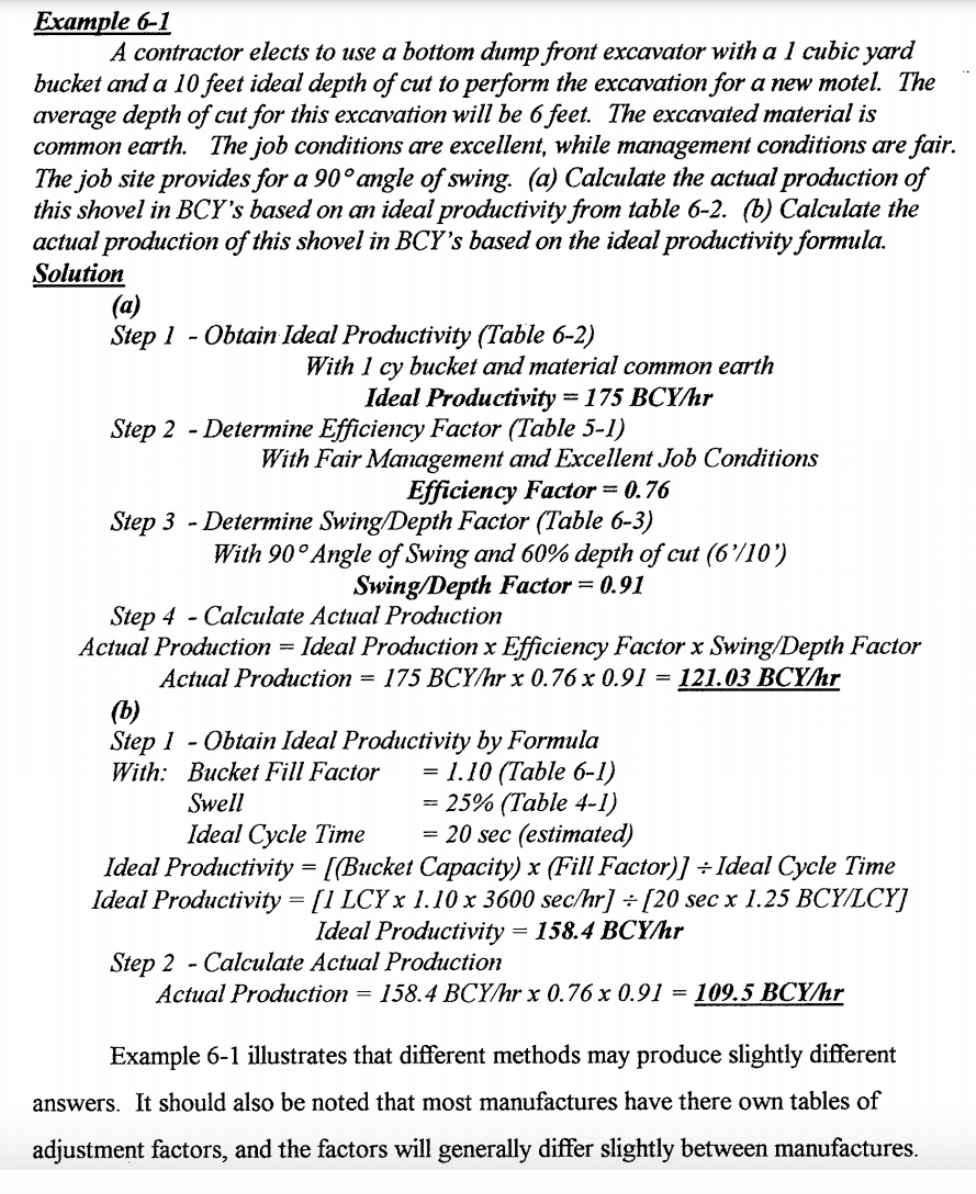

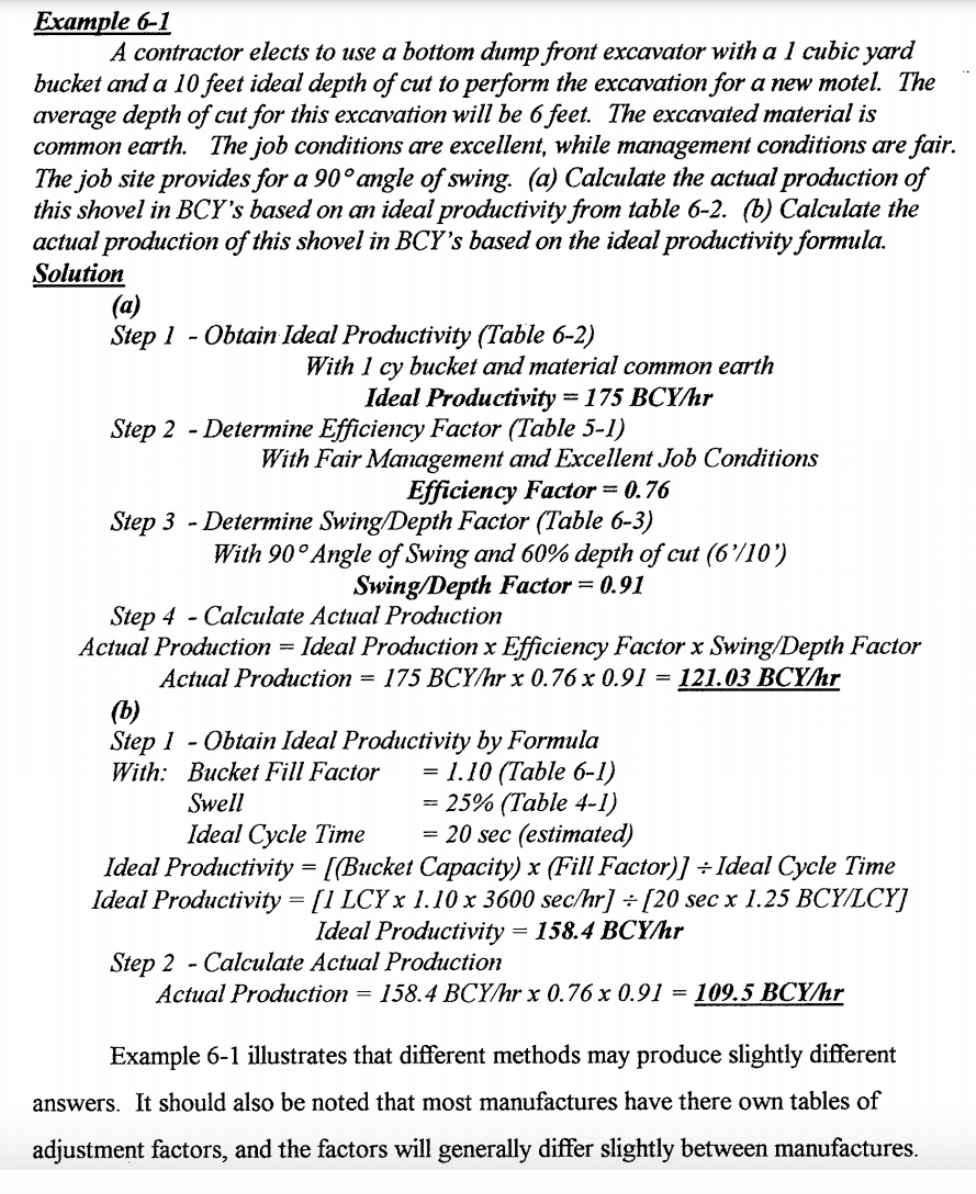

a contractor elects to use a bottom dump front excavator with a 1 cubic yard bucket and a 10 feet ideal depth of cut to perform the excavation for a new motel. The average depth of cut for this excavation will be 6 feet. the excavated material is common earth. The job conditions are excellent, while management conditions are fair. The job site provides for a 90 degree angle of swing.

(a) calculate the actual production of this shovel in BCY;s base on an ideal productivity from table 6-2.

(b) calculate the actual production of this shovel in BCY;s based on the ideal productivity formula

Example 6-1 A contractor elects to use a bottom dump front excavator with a 1 cubic yard bucket and a 10 feet ideal depth of cut to perform the excavation for a new motel. The average depth of cut for this excavation will be 6 feet. The excavated material is common earth. The job conditions are excellent, while management conditions are fair. The job site provides for a 90 angle of swing. (a) Calculate the actual production of this shovel in BCY's based on an ideal productivity from table 6-2. (b) Calculate the actual production of this shovel in BCY's based on the ideal productivity formula. Solution (a) Step 1 - Obtain Ideal Productivity (Table 6-2) With 1 cy bucket and material common earth Ideal Productivity = 175 BCY/hr Step 2 - Determine Efficiency Factor (Table 5-1) With Fair Management and Excellent Job Conditions Efficiency Factor = 0.76 Step 3 - Determine Swing Depth Factor (Table 6-3) With 90 Angle of Swing and 60% depth of cut (6/10) Swing/Depth Factor = 0.91 Step 4 - Calculate Actual Production Actual Production = Ideal Production x Efficiency Factor x Swing/Depth Factor Actual Production = 175 BCY/hr x 0.76 x 0.91 = 121.03 BCYhr (6) Step 1 - Obtain Ideal Productivity by Formula With: Bucket Fill Factor = 1.10 (Table 6-1) Swell = 25% (Table 4-1) Ideal Cycle Time = 20 sec (estimated) Ideal Productivity = [(Bucket Capacity) x (Fill Factor)] + Ideal Cycle Time Ideal Productivity = [1 LCYx 1.10 x 3600 sec/hr] - [20 sec x 1.25 BCYLCY] Ideal Productivity = 158.4 BCYhr Step 2 - Calculate Actual Production Actual Production = 158.4 BCY/hr x 0.76 x 0.91 = 109.5 BCY/hr Example 6-1 illustrates that different methods may produce slightly different answers. It should also be noted that most manufactures have there own tables of adjustment factors, and the factors will generally differ slightly between manufactures. Example 6-1 A contractor elects to use a bottom dump front excavator with a 1 cubic yard bucket and a 10 feet ideal depth of cut to perform the excavation for a new motel. The average depth of cut for this excavation will be 6 feet. The excavated material is common earth. The job conditions are excellent, while management conditions are fair. The job site provides for a 90 angle of swing. (a) Calculate the actual production of this shovel in BCY's based on an ideal productivity from table 6-2. (b) Calculate the actual production of this shovel in BCY's based on the ideal productivity formula. Solution (a) Step 1 - Obtain Ideal Productivity (Table 6-2) With 1 cy bucket and material common earth Ideal Productivity = 175 BCY/hr Step 2 - Determine Efficiency Factor (Table 5-1) With Fair Management and Excellent Job Conditions Efficiency Factor = 0.76 Step 3 - Determine Swing Depth Factor (Table 6-3) With 90 Angle of Swing and 60% depth of cut (6/10) Swing/Depth Factor = 0.91 Step 4 - Calculate Actual Production Actual Production = Ideal Production x Efficiency Factor x Swing/Depth Factor Actual Production = 175 BCY/hr x 0.76 x 0.91 = 121.03 BCYhr (6) Step 1 - Obtain Ideal Productivity by Formula With: Bucket Fill Factor = 1.10 (Table 6-1) Swell = 25% (Table 4-1) Ideal Cycle Time = 20 sec (estimated) Ideal Productivity = [(Bucket Capacity) x (Fill Factor)] + Ideal Cycle Time Ideal Productivity = [1 LCYx 1.10 x 3600 sec/hr] - [20 sec x 1.25 BCYLCY] Ideal Productivity = 158.4 BCYhr Step 2 - Calculate Actual Production Actual Production = 158.4 BCY/hr x 0.76 x 0.91 = 109.5 BCY/hr Example 6-1 illustrates that different methods may produce slightly different answers. It should also be noted that most manufactures have there own tables of adjustment factors, and the factors will generally differ slightly between manufactures