Question: clc clear all close all dt = 0 . 0 1 ; % timestep dx = 0 . 0 1 ; % mesh size n

clc

clear all

close all

dt ; timestep

dx ; mesh size

n ; number of node points

The size and the mesh of plate

Lx ndx; total length in X

Ly Lx; total length in y

xs :dx:Lx; vector of positions in x

ys xs; vector of positions in y

X Y meshgridxs ys; mesh

Ta ; k Temperture of the environment

dTmax ; max temp above the temp of environment

alpha e; thermal diffusivity of copper ms

intial condition

T onesnTa; uniform temperture

T:: Ta dTmax; the hop part temp

c ;

c stands for Periodic boundaries

c stands for Fixed temperature at the boundary

c stands for Insulated BC

c stands for Heat generation with fixed temp BC

q ; the power of the laser focusing on the center of the plate

cp ; heat capacity

rho ; density

for i:runnig thr simulation for cycles s

Tx circshiftT; T shifted to the left aka the right neghbor

Tx circshiftT; T shifted to the right aka the left neghbor

Ty circshiftT; T shifted upwards aka the below neghbor

Ty circshiftT; T shifted downwards aka the above neghbor

the main heat equations

Told T;

T T alphaTxTx TyTyTdxdt; this is all there to it

if cFixed temperature at the boundary

T: Ta;

Tn: Ta;

T: Ta;

T:n Ta;

elseif cinsulated BC

insulated edges

T: Told: alphaTx: Ty:Ty:

Told:dxdt;

left edge,heat flows from right, top, bottom

T:n Told:n alphaTx:n Ty:nTy:nTold:n

dxdt;

right edge,heat flows from left, top, bottom

T: Told: alphaTx: Ty:Tx:

Told:dxdt;

bottom,heat flows from right, top, left

Tn: Toldn: alphaTxn: Txn:Tyn:Toldn:

dxdt;

top edge,heat flows from right, left, bottom

insulated coreners

T Told alphaTx TyTolddxdt;

bottom left corner, heat flows from top and right

Tnn Toldnn alphaTxnn TynnToldnndxdt;

top right corner, heat flows from bottom and left

Tn Toldn alphaTxn TynToldndxdt;

bottom right corner, heat flows from top and left

Tn Toldn alphaTxn TynToldndxdt;

top corner, heat flows from bottom and right

elseif c

T: Ta;

Tn: Ta;

T: Ta;

T:n Ta;

Tn n Tn n qdxdxcprhodt;

end

if modiplotting every th interation

pcolorX Y T

caxisthis fixes the colorbar so that the colors slways

between k

shading interp

colorbar

alternative way to plot

surfX Y T;

axisLxLyTaTadTmax;

shading interp

title t numstrdti s

drawnow

end

end

Can you edit this given matlab code to meet the requirements!

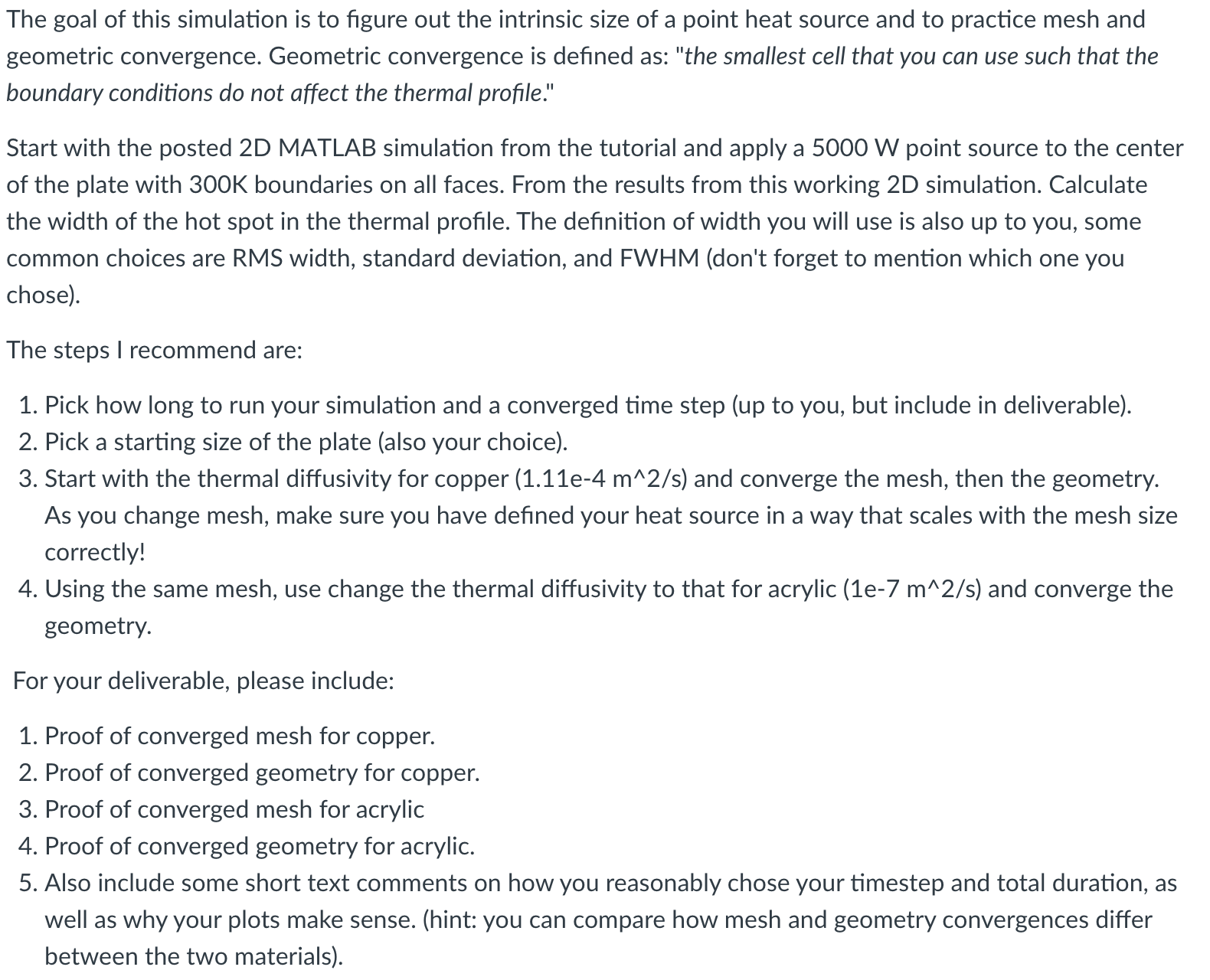

The goal of this simulation is to figure out the intrinsic size of a point heat source and to practice mesh and

geometric convergence. Geometric convergence is defined as: "the smallest cell that you can use such that the

boundary conditions do not affect the thermal profile."

Start with the posted D MATLAB simulation from the tutorial and apply a W point source to the center

of the plate with K boundaries on all faces. From the results from this working D simulation. Calculate

the width of the hot spot in the thermal profile. The definition of width you will use is also up to you, some

common choices are RMS width, standard deviation, and FWHM dont forget to mention which one you

chose

The steps I recommend are:

Pick how long to run your simulation and a converged time step up to you, but include in deliverable

Pick a starting size of the plate also your choice

Start with the thermal diffusivity for copper : ems and converge the mesh, then the geometry.

As you change mesh, make sure you have defined your heat source in a way that scales with the mesh size

correctly!

Using the same mesh, use change the thermal diffusivity to that for acrylic ems and converge the

geometry.

For your deliverable, please include:

Proof of converged mesh for copper.

Proof of converged geometry for copper.

Proof of converged mesh for acrylic

Proof of converged geometry for acrylic.

Also include some short text comments on how you reasonably chose your timestep and total duration, as

well as why your plots make sense. hint: you can compare how mesh and geometry convergences differ

between the two materials

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock