Question: company, not just in manufacturing Propose the basic pattern to implement the Kaizen in an organization. (10 marks) [Total: 30 marks] Question 3: (A) A

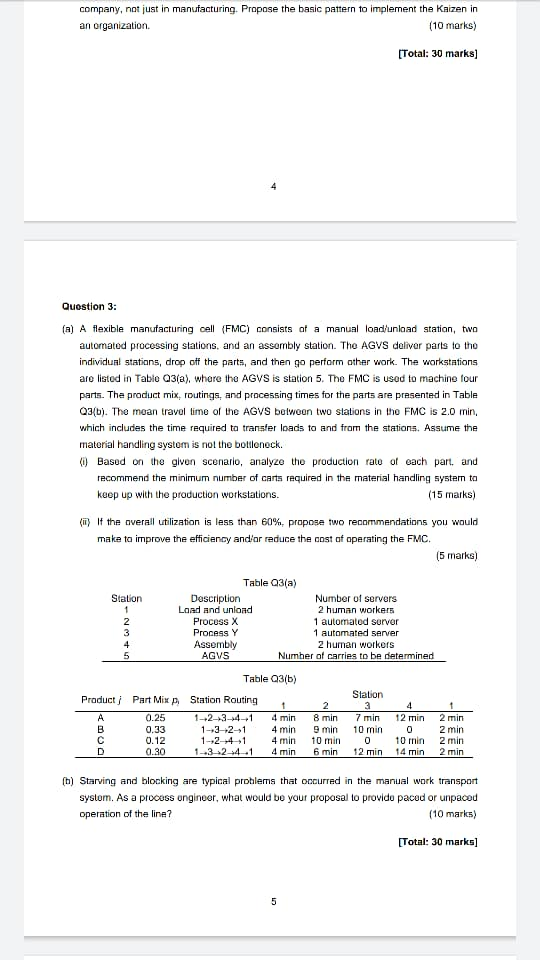

company, not just in manufacturing Propose the basic pattern to implement the Kaizen in an organization. (10 marks) [Total: 30 marks] Question 3: (A) A flexible manufacturing cell (FMC) consists of a manual load/unload station, two automated processing stations, and an assembly station. The AGVS deliver parts to tho individual stations, drop of the parts, and then go perform other work. The workstations are listed in Table 03(a), where the AGVS is station 5. The FMC is used to machine lour parts. The product mix, routings, and processing times for the parts are presented in Table 03(b). The mean travel time of the AGVS bolwoon two stations in the FMC is 2.0 min. which includes the time required to transfer loads to and from the stations. Assume the material handling system is not the bottleneck. (0) Based on the given scenario, analyze the production rate of each part and recommend the minimum number of carts required in the material handling system to keep up with the production workstations. (15 marks) my If the overall utilization is less than 60%, propose two recommendations you would make to improve the efficiency and/or reduce the cost of operating the FMC. (5 marks) Station 1 2 3 4 5 Table 03(a) Description Number of servers Load and unlond 2 human workers Process X 1 automated server Process Y 1 automated server Assembly 2 human workers AGVS Number of carries to be determined Table 93(b) Product Part Mix Station Routing A 0.25 1-2-3-4-1 B 0.33 1--3-2-1 0.12 1-2-4-1 D 0.30 1--3-2-4-1 + 4 min 4 min 4 min 4 min 2 8 min 9 min 10 min 6 min Station 3 7 min 10 min 0 12 min 4 12 min 0 10 min 14 min 2 min 2 min 2 min 2 min (b) Starving and blocking are typical problems that occurred in the manual work transport syslom. As a process ongineer, what would be your proposal to provido pacod or unpacod operation of the line? (10 marks) [Total: 30 marks) 5 company, not just in manufacturing Propose the basic pattern to implement the Kaizen in an organization. (10 marks) [Total: 30 marks] Question 3: (A) A flexible manufacturing cell (FMC) consists of a manual load/unload station, two automated processing stations, and an assembly station. The AGVS deliver parts to tho individual stations, drop of the parts, and then go perform other work. The workstations are listed in Table 03(a), where the AGVS is station 5. The FMC is used to machine lour parts. The product mix, routings, and processing times for the parts are presented in Table 03(b). The mean travel time of the AGVS bolwoon two stations in the FMC is 2.0 min. which includes the time required to transfer loads to and from the stations. Assume the material handling system is not the bottleneck. (0) Based on the given scenario, analyze the production rate of each part and recommend the minimum number of carts required in the material handling system to keep up with the production workstations. (15 marks) my If the overall utilization is less than 60%, propose two recommendations you would make to improve the efficiency and/or reduce the cost of operating the FMC. (5 marks) Station 1 2 3 4 5 Table 03(a) Description Number of servers Load and unlond 2 human workers Process X 1 automated server Process Y 1 automated server Assembly 2 human workers AGVS Number of carries to be determined Table 93(b) Product Part Mix Station Routing A 0.25 1-2-3-4-1 B 0.33 1--3-2-1 0.12 1-2-4-1 D 0.30 1--3-2-4-1 + 4 min 4 min 4 min 4 min 2 8 min 9 min 10 min 6 min Station 3 7 min 10 min 0 12 min 4 12 min 0 10 min 14 min 2 min 2 min 2 min 2 min (b) Starving and blocking are typical problems that occurred in the manual work transport syslom. As a process ongineer, what would be your proposal to provido pacod or unpacod operation of the line? (10 marks) [Total: 30 marks) 5

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts