Question: Concrete Mixture design Additional Example Concrete is required for a slab on grade that will be exposed to moisture in a severe freezethaw environment. A

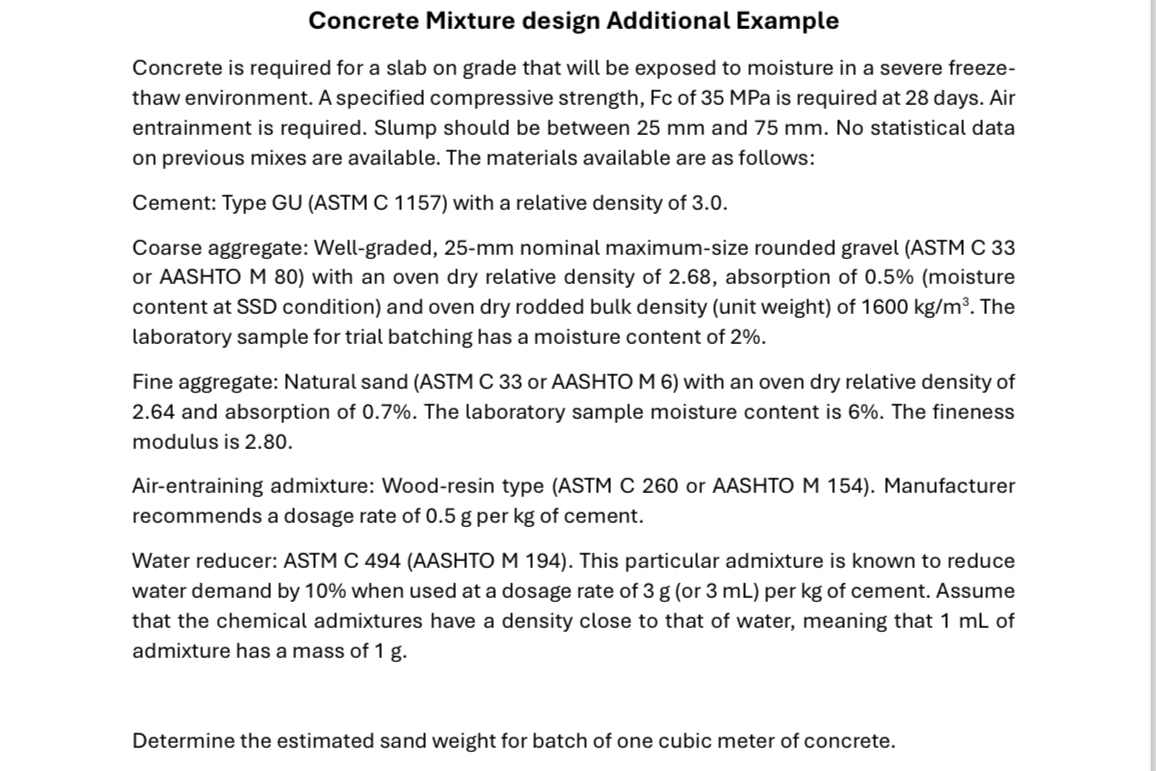

Concrete Mixture design Additional Example

Concrete is required for a slab on grade that will be exposed to moisture in a severe freezethaw environment. A specified compressive strength, of MPa is required at days. Air entrainment is required. Slump should be between and No statistical data on previous mixes are available. The materials available are as follows:

Cement: Type GU ASTM C with a relative density of

Coarse aggregate: Wellgraded, mm nominal maximumsize rounded gravel ASTM C or AASHTO M with an oven dry relative density of absorption of moisture content at SSD condition and oven dry rodded bulk density unit weight of The laboratory sample for trial batching has a moisture content of

Fine aggregate: Natural sand ASTM C or AASHTO M with an oven dry relative density of and absorption of The laboratory sample moisture content is The fineness modulus is

Airentraining admixture: Woodresin type ASTM C or AASHTO M Manufacturer recommends a dosage rate of per of cement.

Water reducer: ASTM C AASHTO M This particular admixture is known to reduce water demand by when used at a dosage rate of or per of cement. Assume that the chemical admixtures have a density close to that of water, meaning that of admixture has a mass of

Determine the estimated sand weight for batch of one cubic meter of concrete.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock