Question: Conduct a simple technoeconomic analysis (TEA) on an idealized process as shown in the Process Flow schematic below. The process consists of a novel reactor

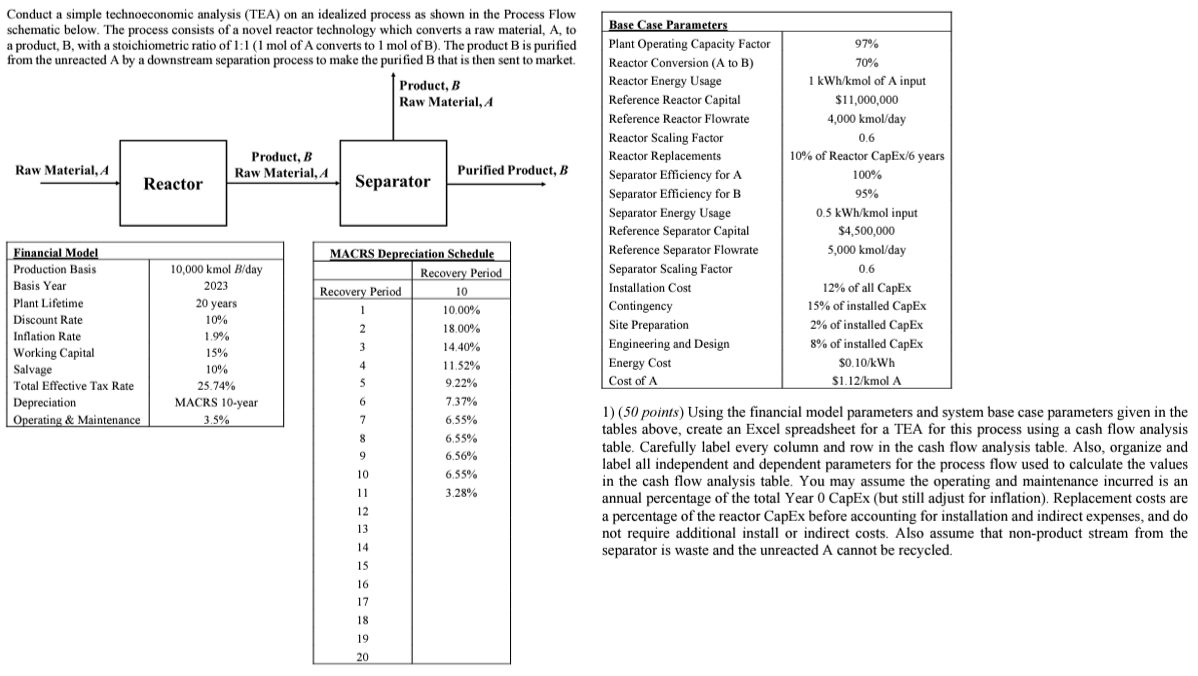

Conduct a simple technoeconomic analysis (TEA) on an idealized process as shown in the Process Flow schematic below. The process consists of a novel reactor technology which converts a raw material, A, to a product, B, with a stoichiometric ratio of 1:1 ( 1mol of A converts to 1mol of B ). The product B is purified 1) (50 points) Using the financial model parameters and system base case parameters given in the tables above, create an Excel spreadsheet for a TEA for this process using a cash flow analysis table. Carefully label every column and row in the cash flow analysis table. Also, organize and label all independent and dependent parameters for the process flow used to calculate the values in the cash flow analysis table. You may assume the operating and maintenance incurred is an annual percentage of the total Year 0 CapEx (but still adjust for inflation). Replacement costs are a percentage of the reactor CapEx before accounting for installation and indirect expenses, and do not require additional install or indirect costs. Also assume that non-product stream from the separator is waste and the unreacted A cannot be recycled. Conduct a simple technoeconomic analysis (TEA) on an idealized process as shown in the Process Flow schematic below. The process consists of a novel reactor technology which converts a raw material, A, to a product, B, with a stoichiometric ratio of 1:1 ( 1mol of A converts to 1mol of B ). The product B is purified 1) (50 points) Using the financial model parameters and system base case parameters given in the tables above, create an Excel spreadsheet for a TEA for this process using a cash flow analysis table. Carefully label every column and row in the cash flow analysis table. Also, organize and label all independent and dependent parameters for the process flow used to calculate the values in the cash flow analysis table. You may assume the operating and maintenance incurred is an annual percentage of the total Year 0 CapEx (but still adjust for inflation). Replacement costs are a percentage of the reactor CapEx before accounting for installation and indirect expenses, and do not require additional install or indirect costs. Also assume that non-product stream from the separator is waste and the unreacted A cannot be recycled

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts